Method for preparing lithium ion battery cathode material Nb2O5 and Li2O doped tellurium and vanadium glass

A technology for lithium ion batteries and negative electrode materials, which is applied in battery electrodes, negative electrodes, secondary batteries, etc., to achieve the effects of shortening the experimental period, good application prospects, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1: TeO 2 :V 2 o 5 :Nb 2 o 5 : Li 2 O=63:27:5:5 molar ratio;

[0030] The specific preparation steps of a lithium ion battery negative electrode material prepared by melt quenching are as follows:

[0031] The first step is to accurately weigh tellurium oxide (TeO 2 ): 6.0381 g, vanadium pentoxide (V 2 o 5 ): 2.9436 g, niobium pentoxide (Nb 2 o 5 ): 0.7967 g, lithium oxide (Li 2 O): 0.2216 g;

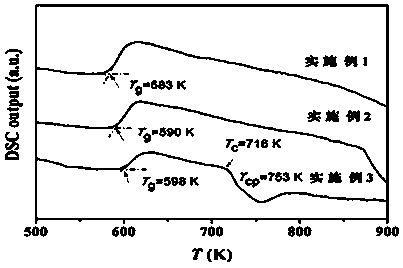

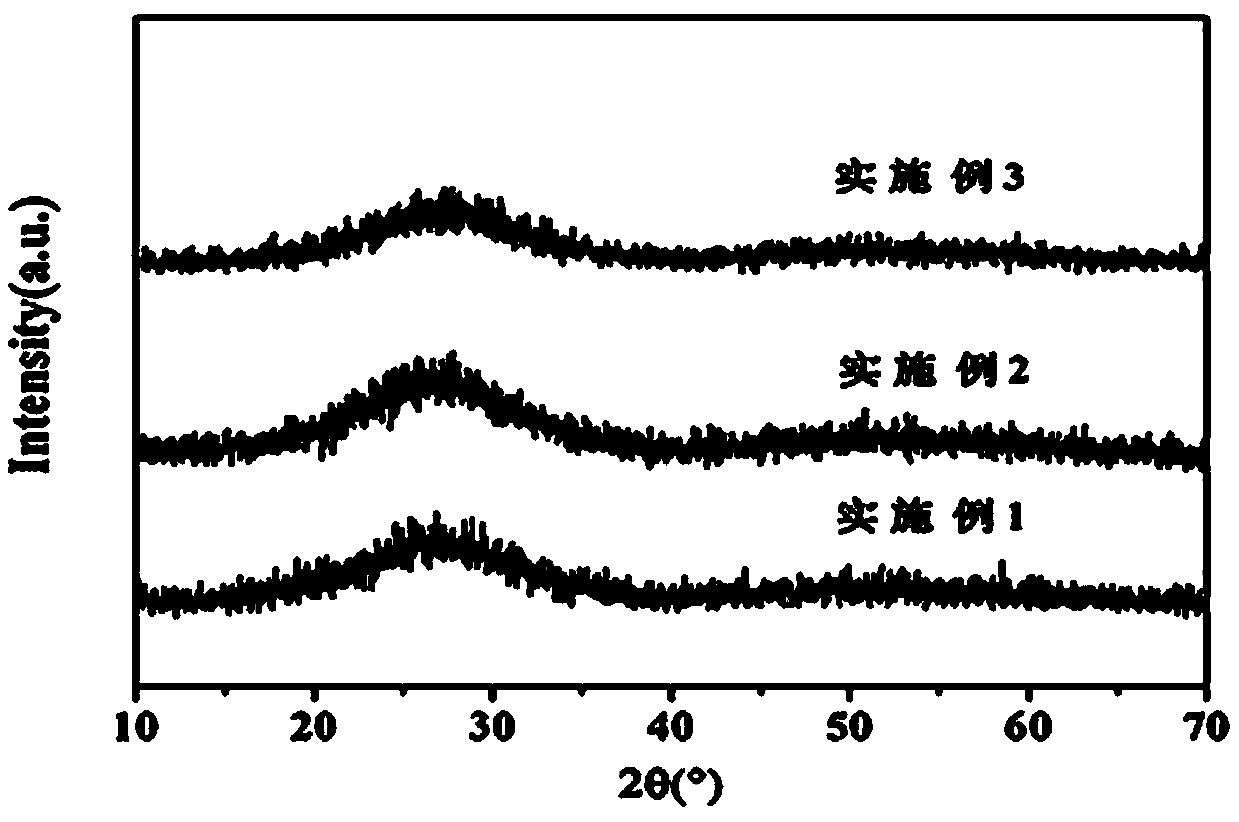

[0032] In the second step, the above-mentioned mixture is fully ground in a mortar, placed in an alumina crucible, melted in an air atmosphere, shaped, annealed, cooled, and finally a glass is obtained. The melting temperature is 900 °C and the holding time is 30 min. The annealing temperature is 250°C and the annealing time is 2 h. The XRD pattern of the prepared sample shows that the sample is amorphous and glass. It can be seen from the DSC pattern that with the doping of Nb 2 o 5 and Li 2 The higher the O content, the higher the glass transition temperat...

Embodiment 2

[0035] Example 2: TeO 2 :V 2 o 5 :Nb 2 o 5 : Li 2 O=56:24:10:10 molar ratio;

[0036] The first step is to accurately weigh tellurium oxide (TeO 2 ): 5.3563 g, vanadium pentoxide (V 2 o 5 ): 2.6162 g, niobium pentoxide (Nb 2 o 5 ): 1.5901 g, lithium oxide (Li 2 O): 0.4424 g;

[0037] In the second step, the above-mentioned mixture is fully ground in a mortar, placed in an alumina crucible, melted in an air atmosphere, shaped, annealed, cooled, and finally a glass is obtained. The melting temperature is 900 °C and the holding time is 30 min. Annealing temperature 250℃, annealing time 2 h;

[0038] In the third step, prepare according to the method in the third step of Example 1.

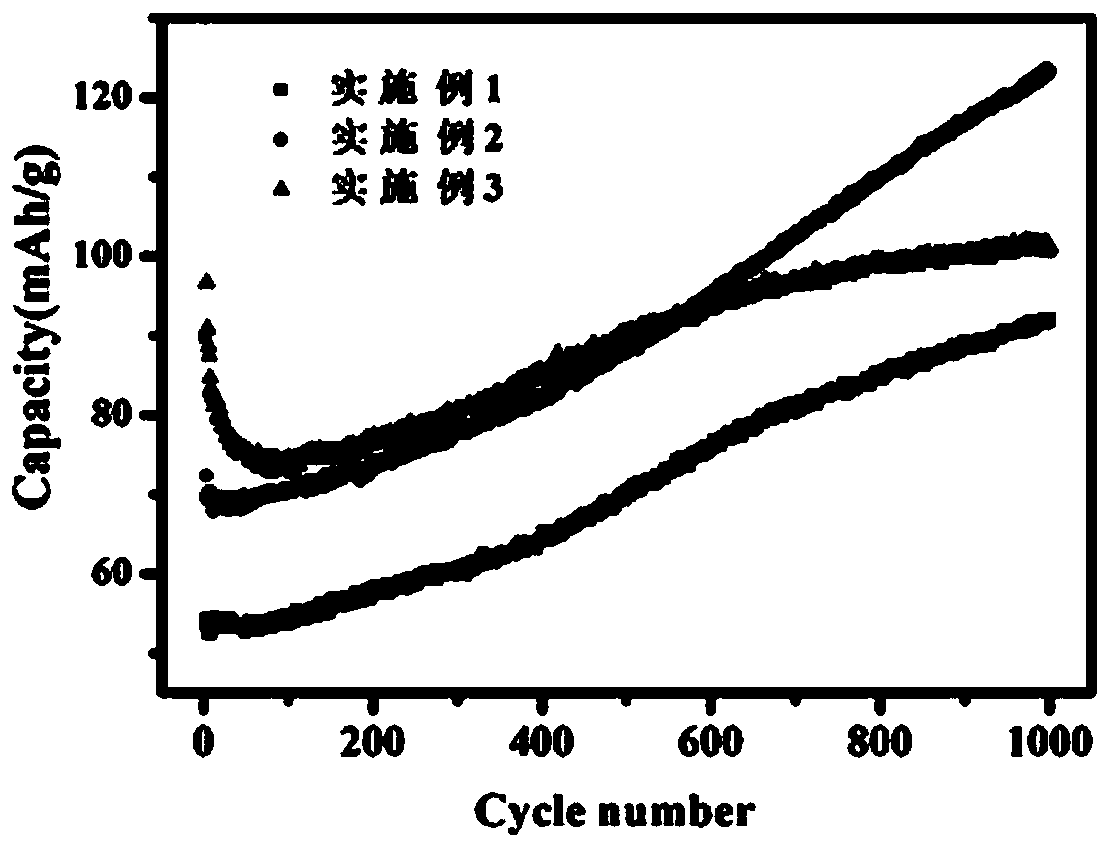

[0039] The negative electrode material prepared by using the above examples is charged and discharged at a charge and discharge voltage of 0.01-3.0 V and a current density of 1000 mA / g. The specific capacity of the first discharge is 72.3 mA h / g. After 1000 cycles, the specific capacity o...

Embodiment 3

[0040] Example 3: TeO 2 :V 2 o 5 :Nb 2 o 5 : Li 2 O=49:21:15:15 molar ratio;

[0041] Step 1: Accurately weigh tellurium oxide (TeO 2 ): 4.6772 g, vanadium pentoxide (V 2 o 5 ): 2.2802 g, niobium pentoxide (Nb 2 o 5 ): 2.3804 g, lithium oxide (Li 2 O): 0.6622 g;

[0042] Step 2: Grind the above-mentioned mixture fully in a mortar, put it in an alumina crucible, melt it in an air atmosphere, shape it, anneal it, cool it, and finally get a glass. The melting temperature is 900°C and the holding time is 30 minutes. The annealing temperature was 250°C, and the annealing time was 2 h.

[0043] The 3rd step, prepare according to the method for the 3rd step of embodiment 1;

[0044] The negative electrode material prepared by using the above examples is charged and discharged at a charge and discharge voltage of 0.01-3.0 V and a current density of 1000 mA / g. The specific capacity of the first discharge is 96.7 mA h / g. After 1000 cycles, the specific capacity of the disch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com