Biodegradable composite hydrogel and a preparation method and application thereof

A composite hydrogel, biodegradation technology, applied in the application of adsorbing heavy metals, degradable composite hydrogel and its preparation field, can solve the problems of weak hydrogel strength, poor mechanical strength, application limitations, etc. Low cost, improved mechanical properties and stability, low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: the preparation of PSI

[0036] Take 39.6 parts of maleic anhydride in the reactor, add 40 mL of deionized water, and hydrolyze at 60°C for 30 minutes. Next, ammonia water was added under ice-water bath conditions, wherein the molar ratio of ammonia water to maleic anhydride was 1.2:1, and then the temperature was raised to 85° C. for 2 h, and then dried to obtain a white ammonium salt solid for later use. Take 20 parts of ammonium salt and 2 parts of solid acid catalyst into the reaction kettle, then add 200mL of propylene carbonate, open the reaction kettle, polymerize at a constant temperature of 180°C for 2 hours, cool down to 80°C after completion, turn off the instrument, and take out The reaction solution. Add absolute ethanol to the reaction solution, extract and separate the liquid to obtain the intermediate product polysuccinimide (PSI), and obtain the PSI solid for future use after drying.

[0037] The molecular weight distribution of the PSI ...

Embodiment 2

[0038] Embodiment 2: the preparation of hydrogel:

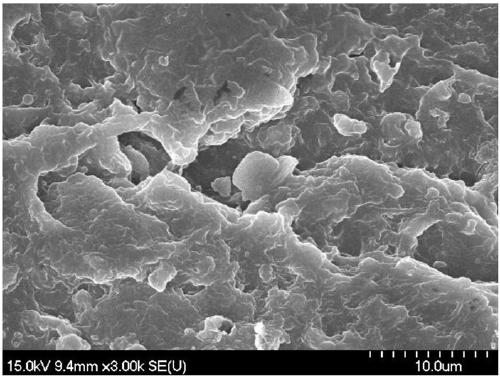

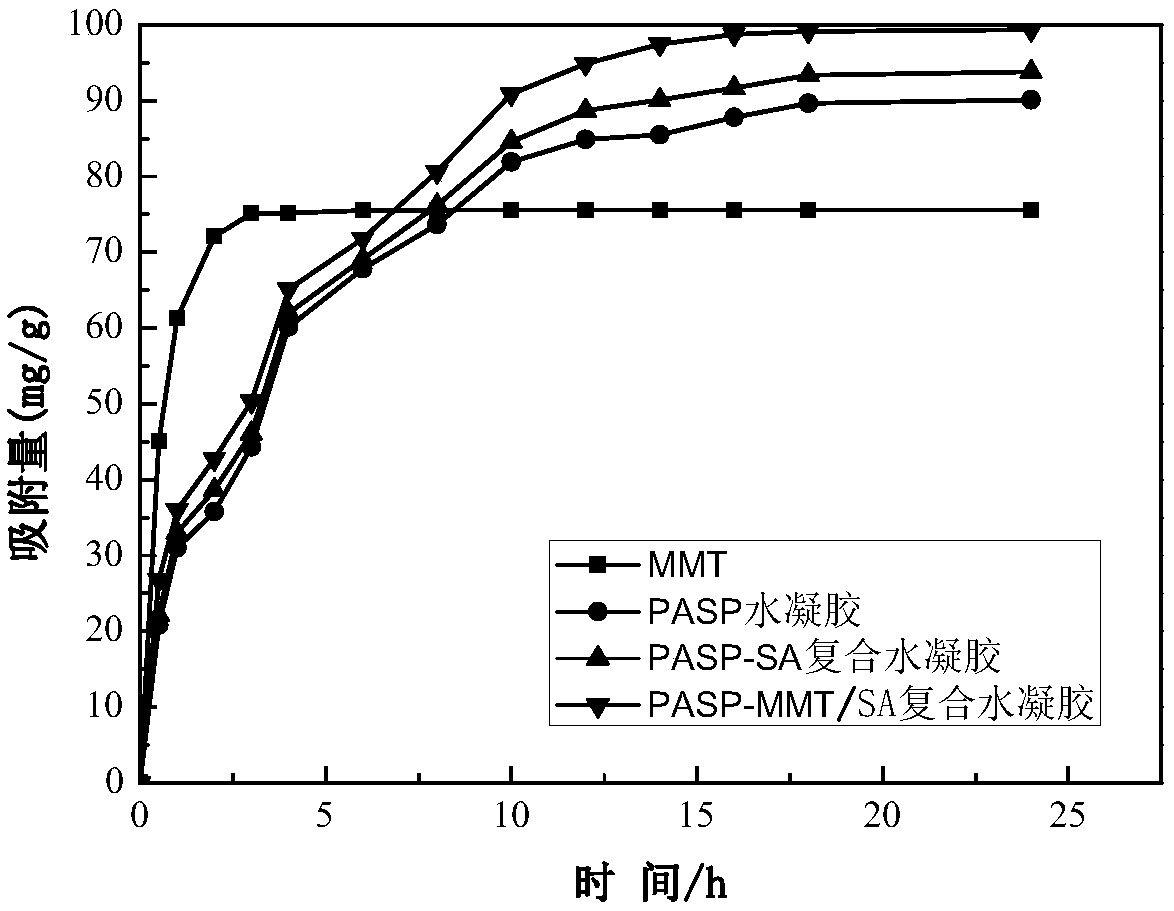

[0039](1) Take 4g PSI and disperse it in a beaker with 20mL deionized water for magnetic stirring, then add 1g linear polymer sodium alginate (purchased by Aladdin, viscosity 200±20mpa.s) and 2g montmorillonite (add Ultrasound is required for 0.5h to disperse evenly). After mixing evenly, add 15 mL of hydrazine hydrate (crosslinking agent) with a mass fraction of 98% and 10 mL of NaOH (hydrolyzing agent) solution with a concentration of 2 mol / L, and make the mixed solution at a pH of 9 to 10 at a room temperature of 20°C-30°C. Stirring reaction is carried out under the environment of environment, and cross-linking, hydrolysis are simultaneously carried out in the process, and reaction is completed after 8 hours, and the precipitate produced is the required composite hydrogel.

[0040] (2) washing the hydrogel to remove unreacted chemical substances therein; it can be washed directly, or can be washed with water after removin...

Embodiment 3

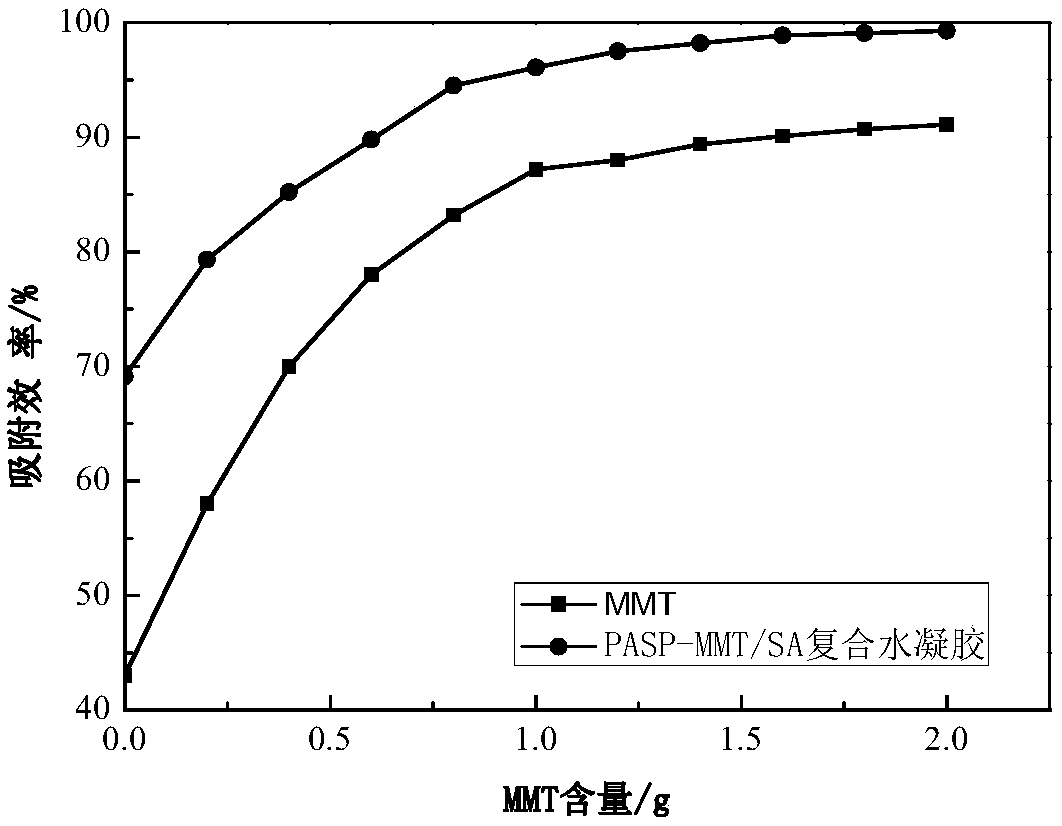

[0042] It is basically the same as Example 2, except that the addition amount of montmorillonite is changed to 0.2g, 0.4g, 0.6g, 0.8g, 1g, 1.2g, 1.4g, 1.6g, 1.8g to obtain a degradable composite Hydrogels.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com