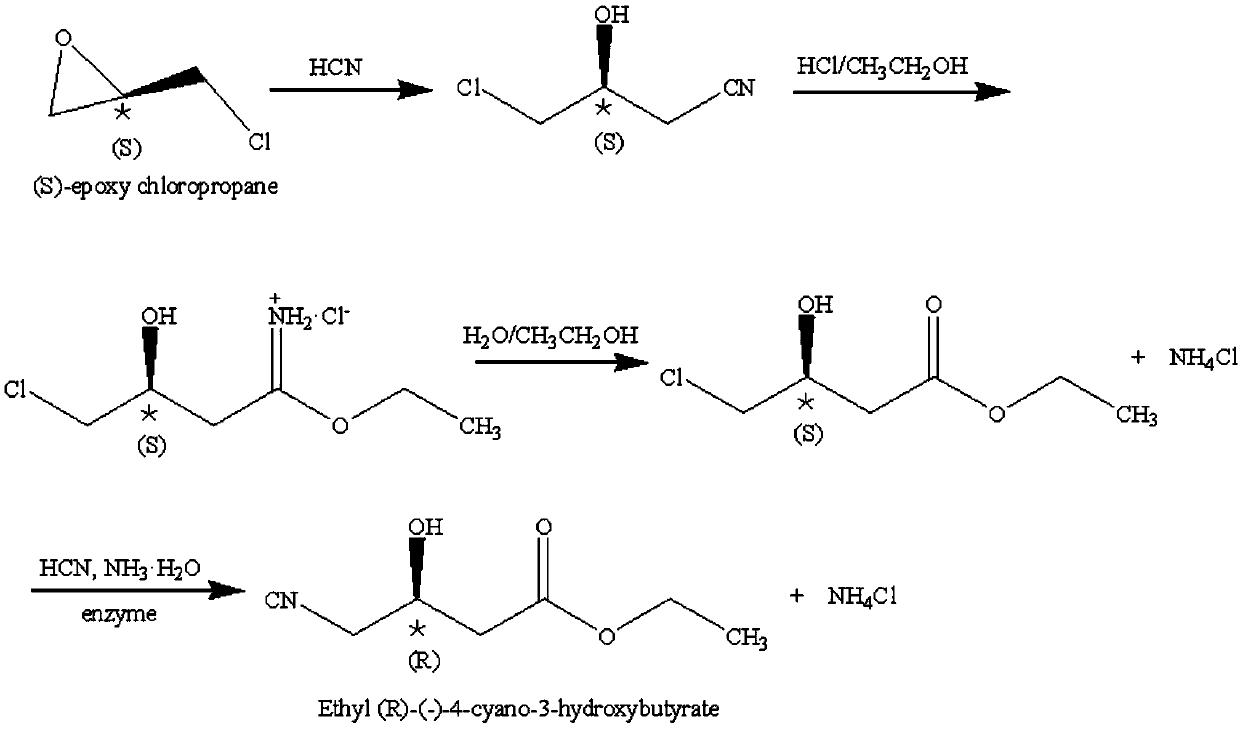

Environmental protection preparation method of (R)-(-)-4-cyano-3-hydroxy ethyl butyrate

A green and environmentally friendly technology of ethyl hydroxybutyrate, which is applied in the fields of medicine and chemical industry, can solve the problems of poor atom economy, high preparation cost, and low yield, and achieve the effects of low production cost, simple preparation process, and few by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

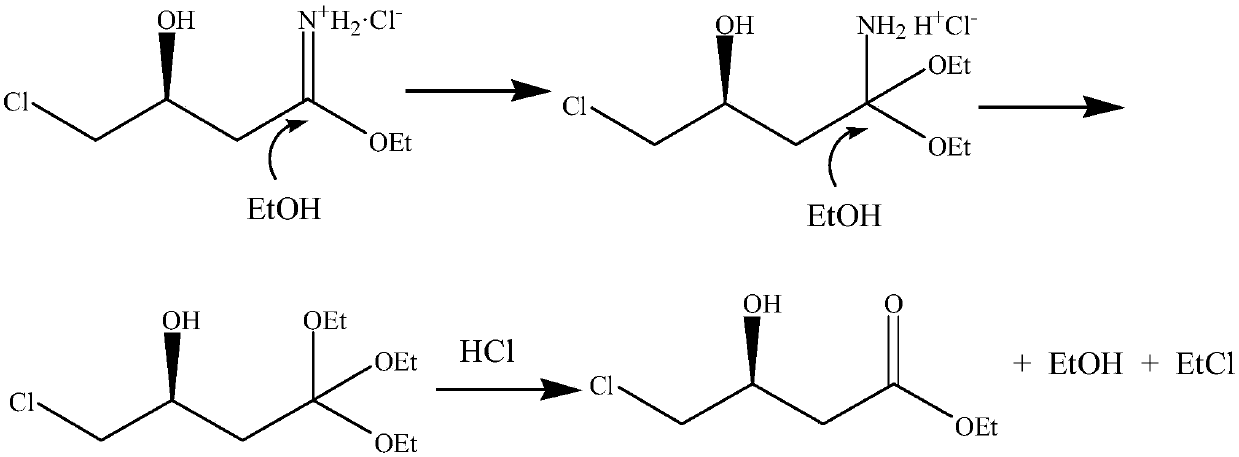

Method used

Image

Examples

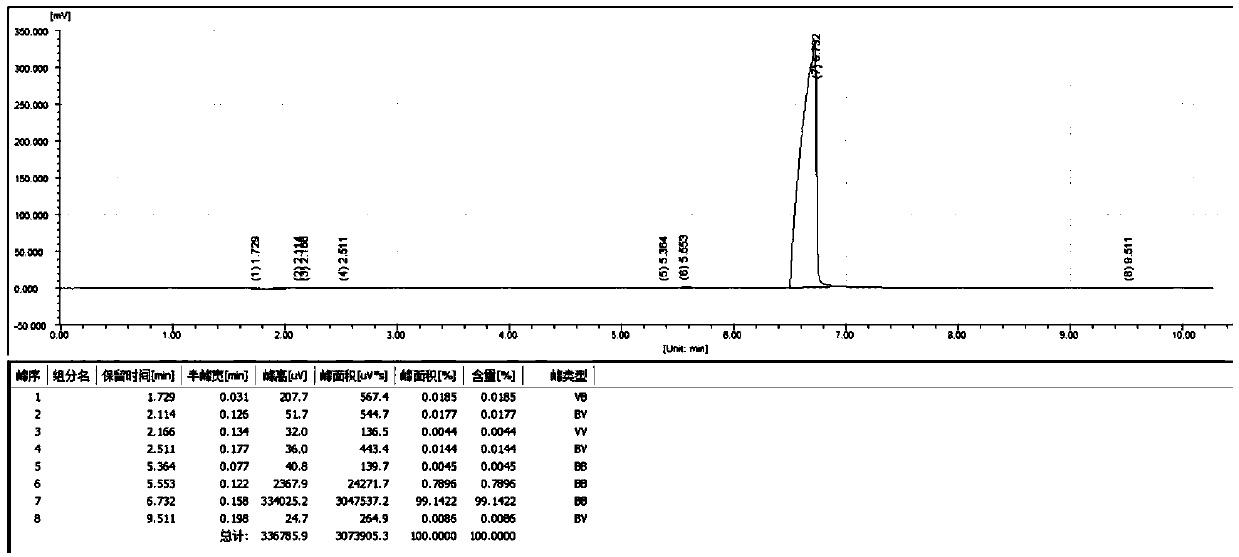

Embodiment 1

[0066] Embodiment 1 prepares (S)-(-)-4-chloro-3-hydroxybutyronitrile

[0067] Add 100g (1.08mol) (S)-epichlorohydrin, 200g water and 2g diethylamine into a 1000mL three-necked flask at one time, stir and mix for 5min to obtain a mixed solution, and drop 1-2 drops per second under the condition of 20°C Add 37.9g (1.40mol) of liquid hydrocyanic acid to the above-mentioned mixed solution at a speed of 20°C, continue stirring and reacting for 10h to obtain a reaction solution, adjust the pH value of the reaction solution to 5 with 50% sulfuric acid, and distill under reduced pressure Remove water, then high vacuum rectification obtains 119.6g content 99.14% (specific rotation [α] D 25 =-16.8°) of (S)-(-)-4-chloro-3-hydroxybutyronitrile, yield 92.71%.

Embodiment 2

[0068] Embodiment 2 prepares (S)-(-)-4-chloro-3-hydroxybutyronitrile

[0069] Add 100g (1.08mol) (S)-epichlorohydrin, 200g water and 2g diethylamine into a 1000mL three-neck flask at one time, stir and mix for 5 minutes to obtain a mixed solution, and at 25°C, 1-2 drops per second Add 43.8g (1.62mol) of liquid hydrocyanic acid to the above-mentioned mixed solution at a speed of 25°C, continue to stir and react for 6h to obtain a reaction solution, adjust the pH value of the reaction solution to 5 with 50% sulfuric acid, and distill under reduced pressure Remove water, then high vacuum rectification obtains 122.5g content 99.34% (specific rotation [α] D 25 =-17.0°), (S)-(-)-4-chloro-3-hydroxybutyronitrile, yield 94.96%.

Embodiment 3

[0070] Embodiment 3 prepares (S)-(-)-4-chloro-3-hydroxybutyronitrile

[0071] Add 100g (1.08mol) (S)-epichlorohydrin, 200g water and 2g diethylamine into a 1000mL three-neck flask at one time, stir and mix for 5 minutes to obtain a mixed solution, and at 25°C, 1-2 drops per second Add 30% sodium cyanide solution and 50% sulfuric acid to the above-mentioned mixed solution at the same speed, continue to stir and react for 12 hours at 25°C to obtain a reaction solution, adjust the pH value of the reaction solution to 5 with 50% sulfuric acid, reduce Press distillation to remove water, filter to remove salt, then high vacuum rectification to obtain 105g content 99.06% (specific rotation [α] D 25 =-16.9°) of (S)-(-)-4-chloro-3-hydroxybutyronitrile, yield 81.26%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com