Method for testing and determining rutile TiO2 in titanium ore

A technology of rutile type and titanium ore, which is applied in the preparation of test samples, thermal excitation analysis, material excitation analysis, etc., can solve the problems of low accuracy, low method confidence, and long operation cycle, etc. Reproducibility and accuracy, wide detection range and fast analysis speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] The present embodiment provides a kind of method for measuring rutile TiO in titanium ore, specifically:

[0077] 1) Weigh 0.2000g (accurate to 0.0001g) titanium ore ore sample, add 50ml (2+1) HCl (hydrochloric acid to water ratio 2:1) and 2.0g NaF mixed solvent, cover with a watch glass, in boiling water Dissolve ore in the bath for 1.5 hours, stirring continuously during the period; then cool, filter with slow dense quantitative filter paper, and wash the residue with hot water for 5-6 times;

[0078] 2) Remove the residue together with the filter paper and place it in a high-alumina crucible, start ashing in a muffle furnace from a low temperature (below 300°C) (open the furnace door for ashing, close the furnace door after the smoke is exhausted), and reach 700 °C ℃, a total of 20 minutes, take it out, cool, add 1g of sodium hydroxide, shake well, cover the surface with a little sodium peroxide (about 0.2g), and melt ore in a muffle furnace at 700℃ for 10 minutes; ...

experiment example

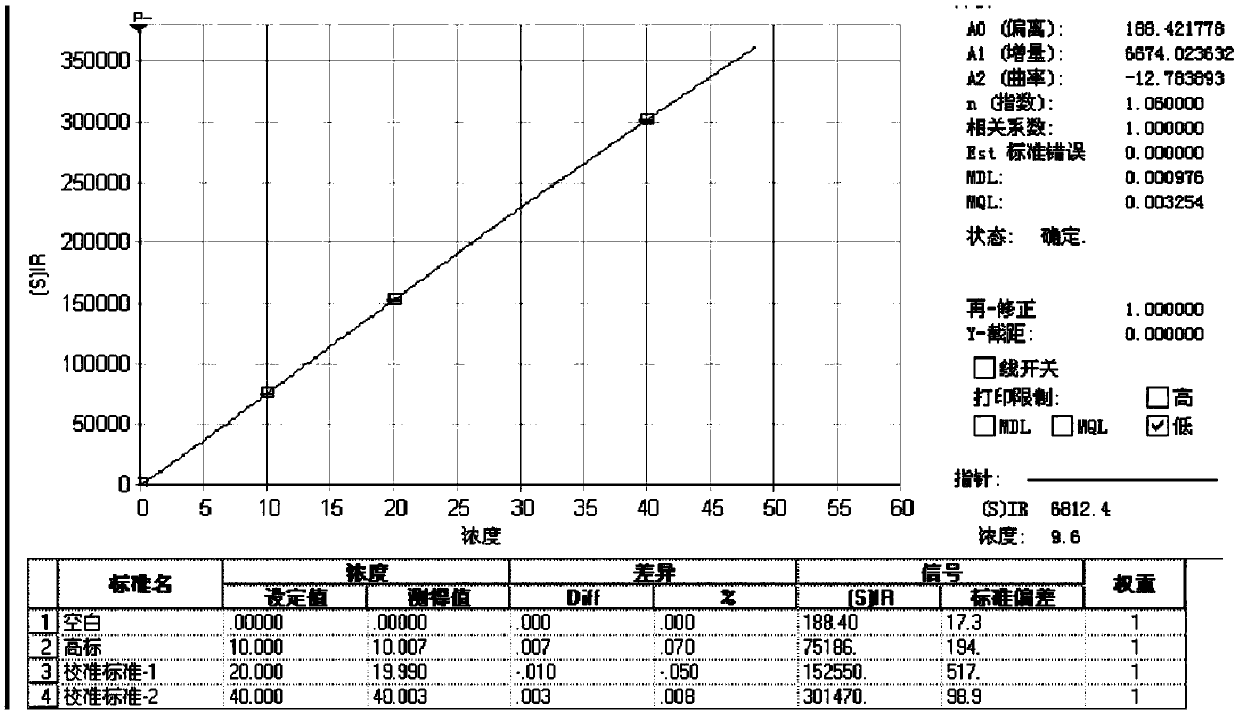

[0094] 1. Method detection limit

[0095] According to the test procedure, prepare 12 blank solutions that do not contain the element to be tested but contain the matrix, adjust the instrument to the best experimental conditions, and measure the 12 blank solutions. Within the selected confidence level, the result is 3 times the standard deviation The corresponding concentration is used as the method detection limit (LD), and the measured method detection limit is shown in Table 3.

[0096] Table 3 method detection limit

[0097]

[0098] The detection limit of this method is 0.0049%, which has a good detection limit. Meet the quality requirements for experimental data in the "Quality Management Specifications for Geological and Mineral Laboratory Testing".

[0099] 2. Method precision

[0100] In the outsourced analysis project of this laboratory (geological survey samples in XXX District, XXX City), 12 samples were randomly selected, and 12 solutions were dissolved acco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com