Hydrogenation catalyst used for petroleum resin and preparation method and application of catalyst

A technology of hydrogenation catalyst and petroleum resin, which is applied in the direction of catalyst activation/preparation, chemical instrument and method, metal/metal oxide/metal hydroxide catalyst, etc. Problems such as difficulty in hydrogen, poor hue of C5 petroleum resin, etc., achieve the effects of improving thermal stability and oxidation resistance, simplifying composition, and improving product appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

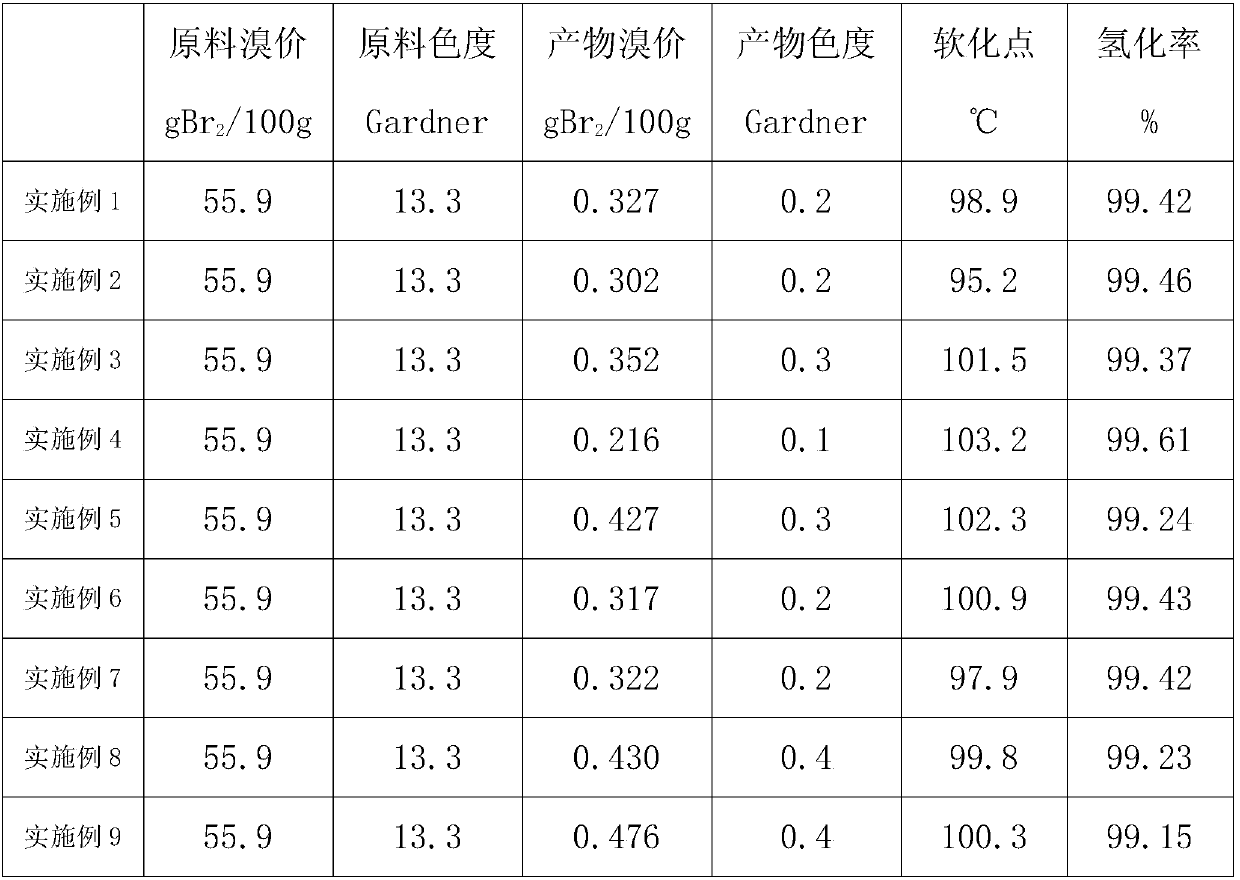

Examples

preparation example Construction

[0021] The invention provides a hydrogenation catalyst for petroleum resin and its preparation method and application. The hydrogenation catalyst is metal nickel loaded on an alumina-titania composite carrier, wherein the mass ratio of alumina to titania is 2-7:1-3, the mass percentage of nickel is 18wt%-25wt%.

[0022] The specific surface area of the hydrogenation catalyst is 90m 2 / g~150m 2 / g, the pore volume is 0.4cm 3 / g~0.6cm 3 / g.

[0023] The nickel salt solution is completely dissolving one or more of nickel nitrate, nickel acetate, nickel sulfate and nickel chloride in a solvent, wherein the solvent is one or both of ethanol and deionized water.

[0024] There is also an additive in the nickel salt solution, and the additive is added after the nickel salt is completely dissolved; the mass percentage of the additive and the solvent in the nickel salt solution is 2wt% to 5wt%; the additive is citric acid and cetyl tris One or both of methyl ammonium bromide.

...

Embodiment 1

[0036] Preparation of alumina

[0037] Boehmite was calcined at 550°C for 4 hours to obtain alumina with a specific surface area of 251.27m 2 / g, the pore volume is 0.60cm 3 / g, the pore size is 8nm.

[0038] Preparation of alumina-titania composite support

[0039] Add 19.17g of tetrabutyl titanate into 76.68mL of absolute ethanol, stir to dissolve it, and obtain an ethanol solution of tetrabutyl titanate; then add 10.5g of alumina prepared above, and add dropwise the solution containing A mixed solution of water ethanol, glacial acetic acid and deionized water, wherein, in the ethanol solution of titanium salt, the titanium salt is tetrabutyl titanate, and the volume ratio of tetrabutyl titanate to ethanol is selected as 5:20; The volume ratio of ethanol, deionized water and glacial acetic acid in the mixed solution containing ethanol, glacial acetic acid and deionized water is 5:2:2; after that, soak for 6 hours at 40°C under continuous stirring to make tetrabutyl tita...

Embodiment 2

[0043] The difference from Example 1 is that the nickel salt solution also contains the additive citric acid, after the nickel salt is completely dissolved, the additive (citric acid) is added to dissolve, and finally the aluminum oxide-titania composite carrier is added for impregnation. The ratio of the mass of citric acid to the volume of deionized water is 3:80 (g / mL).

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com