Hydrogenation catalyst and preparation method thereof and preparation method of tetrahydrofurfuryl alcohol

A hydrogenation catalyst and catalyst technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as increased cost and separation difficulty, increased production cost, increased risk, etc., to reach the price Low cost, reduced operating costs, and reduced intermediate steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] In a second aspect, the present invention provides a method for preparing a hydrogenation catalyst, wherein the method comprises: co-processing a mixed aqueous solution containing a silicon oxide precursor, a nickel oxide precursor, a calcium carbonate precursor, and a zirconia precursor precipitation, and the resulting precipitate was dried and roasted.

[0022] In the present invention, the mixed aqueous solution can be prepared in a conventional preparation manner in the art, preferably first preparing an aqueous solution containing a silicon oxide precursor, an aqueous solution containing a nickel oxide precursor, an aqueous solution containing a calcium carbonate precursor, and an aqueous solution containing a Aqueous solutions of zirconia precursors, and then measure the required solutions separately and mix them.

[0023] In the present invention, preferably, the reaction conditions of the co-precipitation include: a temperature of 40-70° C., and a pH value of 6-...

Embodiment 1-7

[0044] Prepare 25% by weight of acidic silica sol, 1.5M Ni(NO 3 ) 2 ·8H 2 O. solution, 1.5M Ca(NO 3 ) 2 4H 2 O and 1.5M ZrOCl 2 ·8H 2 O spare.

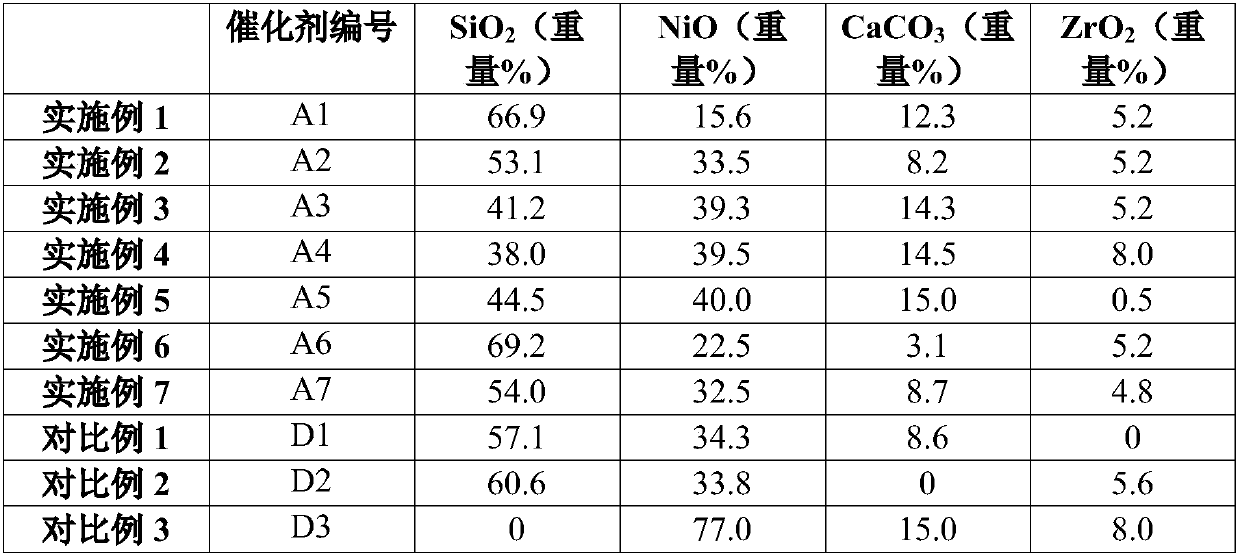

[0045] Accurately measure the above four solutions according to the component content of the catalyst to form a silicon-nickel-calcium-zirconium mixed solution, wherein the amount of each solution makes the content of each component in the final prepared catalyst meet the values shown in Table 1. Add 100mL of deionized water into the reactor, and under continuous stirring, add the silicon-nickel-calcium-zirconium mixed liquid and 1M sodium carbonate solution into the reactor in parallel to control the reaction pH value to 8.5, and at the same time, the reaction liquid The temperature rises to 60°C, after the feeding is completed, continue to heat and stir for 1 hour, filter, dry at 110°C for 12 hours, and then roast in a muffle furnace at 500°C for 4 hours to obtain a catalyst powder sample, and add Zhan catalyst to the obtai...

Embodiment 8-14

[0055] React in a stainless steel reactor to prepare tetrahydrofurfuryl alcohol. Specifically, the hydrogenation catalyst and furfural / water solution (furfural concentration is 70% by weight) will be selected from the hydrogenation catalyst prepared in the above-mentioned examples 1-7 to react, and the reaction temperature 140℃, hydrogen pressure 4MPa, liquid hourly space velocity 0.1hr -1 , the hydroaldehyde molar ratio is 1. After the reaction was stable, the reaction result was analyzed by gas chromatography, and the conversion rate of furfural and the selectivity of tetrahydrofurfuryl alcohol were shown in Table 2 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com