Ceramic particle preparation production line adopting tail gas secondary-combustion process

A technology of secondary combustion and secondary combustion chamber, which is applied in the direction of manufacturing tools, ceramic molding machines, ceramic molding workshops, etc., can solve the problems of increasing equipment investment and material costs, improve sintering quality, reduce organic content, The effect of reducing the burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

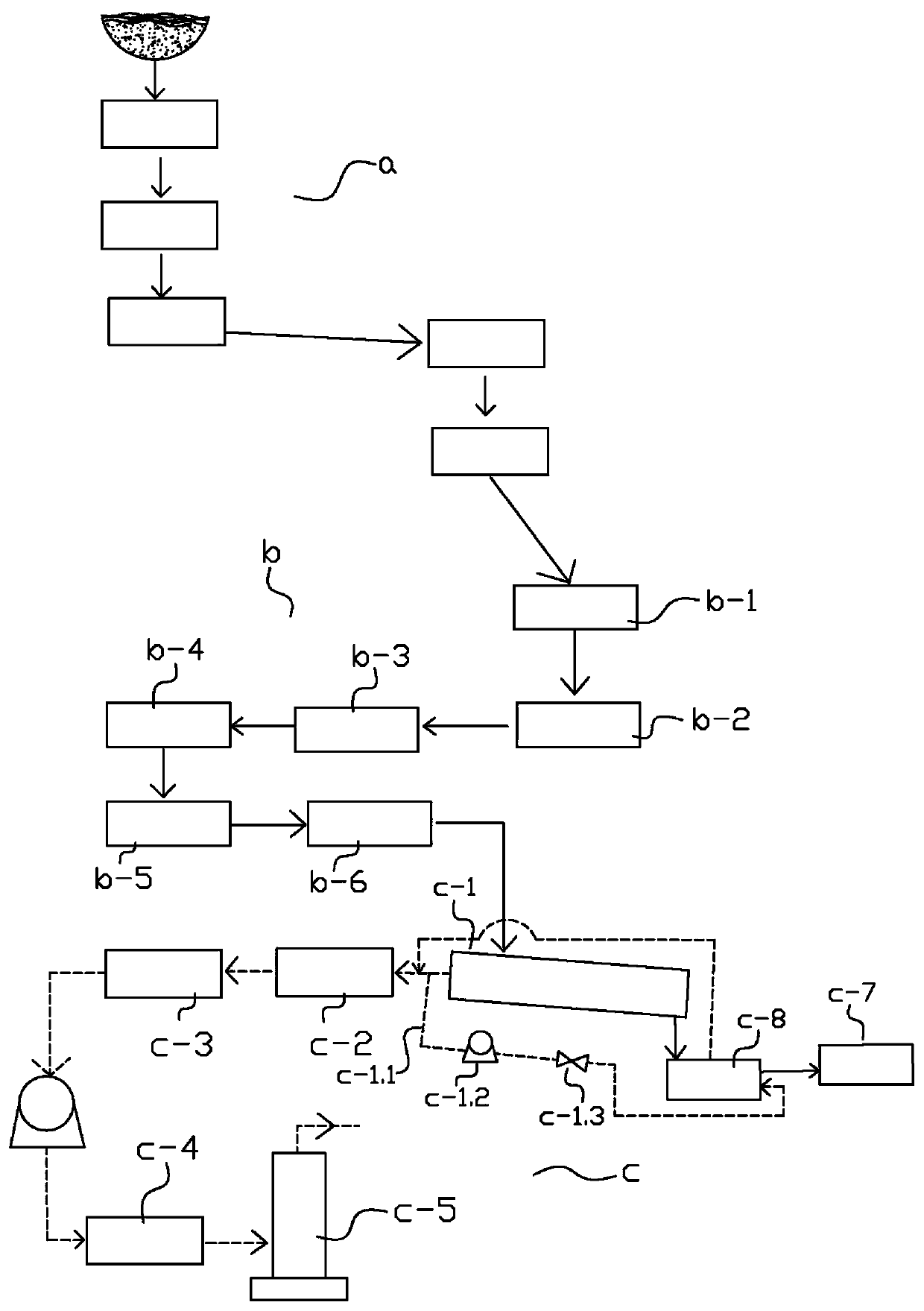

[0038] Example 1: Reference figure 1 , the ceramsite preparation production line using the tail gas secondary combustion process, including:

[0039] A ceramsite raw material mixing supporting equipment group a, which is composed of a plurality of raw material supply lines and a stirring device, and the raw material supply line transports the raw materials to the stirring device after crushing and stirring;

[0040] A ceramsite raw material forming supporting equipment group b, which undertakes the raw material mixed by the ceramsite raw material mixing supporting equipment group a, and the raw material passes through the aging material warehouse b-1, the raw material rolling machine b-2, the second double Shaft mixer b-3, granulating ball machine b-4, round roller sieve b-5 and kiln feeder b-6 to form granular ceramsite blanks;

[0041] A ceramsite sintering equipment group c, including a rotary kiln c-1 for sintering ceramsite raw materials, a return branch c-1.1 is set on ...

Embodiment 2

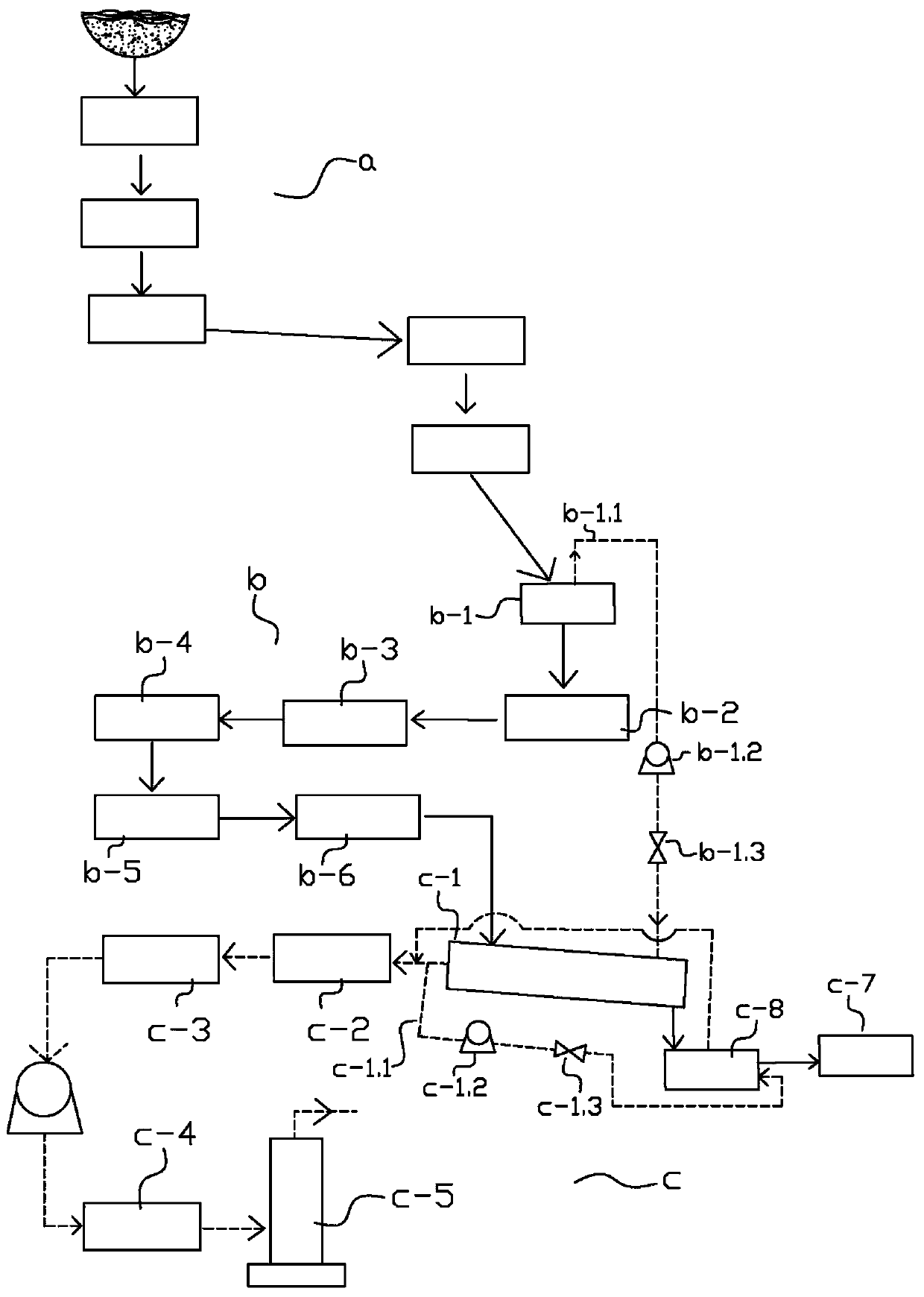

[0046] Example 2: Reference figure 2 , the ceramsite preparation production line that adopts tail gas secondary combustion process differs from embodiment 1 in that: it also includes an aging material warehouse b-1, and the ceramsite raw material that contains municipal sludge and industrial sludge is mixed and After proportioning, it is stored in it. The aged material warehouse b-1 is provided with a waste gas supplementary air branch b-1.1, and the aged material warehouse b-1 removes the raw material inlet, the raw material outlet and the exhaust gas supplementary air branch There is no opening outside the connecting port of b-1.1, that is, when the material does not circulate, the aging material warehouse b-1 is airtight;

[0047] The waste gas supplementary air branch b-1.1 inputs the volatilized waste gas in the aged material warehouse b-1 into the rotary kiln c-1 for secondary combustion, and the exhaust gas supplementary air branch b-1.1 is provided with exhaust gas th...

Embodiment 3

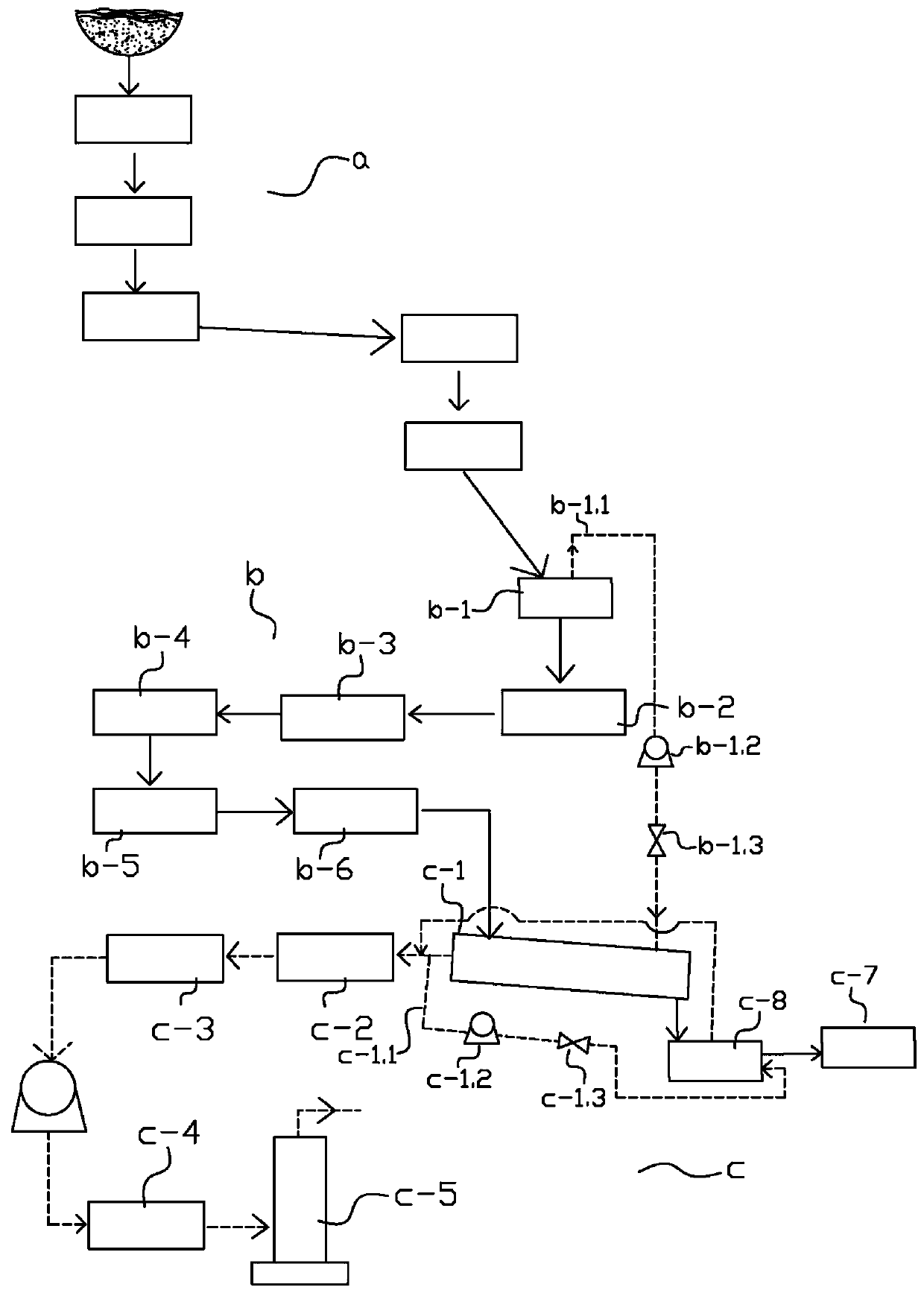

[0048] Example 3: Reference image 3 , the ceramsite preparation production line that adopts tail gas secondary combustion process differs from Example 2 in that: it also includes a cooling kiln c-7 connected to the rear of the secondary combustion chamber c-8, and the return branch c-1.1 will Part of the tail gas is delivered to the secondary combustion chamber c-8 to pre-cool the materials therein.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com