Silicon dioxide-protected carbon-based catalyst as well as preparation method and application thereof

A carbon-based catalyst, silica technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of carbon material pore collapse, few catalytic active sites, affecting catalytic performance, etc. , to achieve the effect of improving electrocatalytic performance, avoiding the reduction of specific surface area, and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The preparation method of the carbon-based catalyst protected by silicon dioxide of the present invention, the specific steps are as follows:

[0041] (1) SiO 2 Coating steps:

[0042] Dissolve ethyl orthosilicate, catalyst, and solid carbon source containing metal and nitrogen in a mixed solvent of water and alcohol, and carry out a stirring reaction; after the reaction, filter the resulting precipitate and wash it with ethanol until the supernatant is neutral , dried to obtain a coated product;

[0043] (2) High temperature annealing steps:

[0044] The coated product is subjected to high temperature treatment in an inert atmosphere to obtain an intermediate product;

[0045] (3) Removal of SiO 2 step:

[0046] The intermediate product obtained in step (2) is acid-washed or alkali-washed, etched and removed from the surface of SiO 2 coating layer to obtain a carbon-based catalyst.

[0047] In step (1), the solid carbon source containing metal and nitrogen is a ze...

Embodiment 1

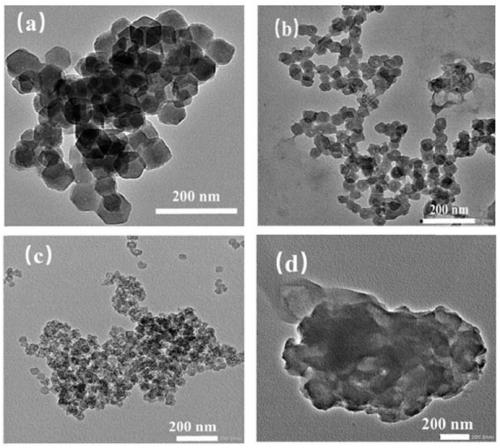

[0062] ① 1mmol (241.86mg) of iron nitrate, 30mmol (8.92g) of zinc nitrate, and 240mmol (19.70g) of dimethylimidazole were weighed according to the corresponding molar ratio, and the metal salts of iron nitrate and zinc nitrate were dissolved in 500mL of methanol. Methimidazole was dissolved in 400 mL of methanol. Then the metal salt solution was slowly added to dimethylimidazole and stirred for 2h. The product is obtained by centrifugation, and the product is washed two to three times with methanol, and dried overnight to obtain the iron-zinc bimetallic ZIF (recorded as Fe-ZIF, TEM sees figure 1 (a)).

[0063] ② Dissolve 600mg of iron-zinc bimetallic ZIF in 240mL of water, add cetyltrimethylammonium bromide solution 6mL (25mg / mL), NaOH solution 10mL (6mg / mL) and tetraethyl orthosilicate solution 1.2mL Dissolve in 6mL of methanol, stir at 25°C for 0.5h; centrifuge, wash with ethanol, and dry to obtain a coated sample (referred to as Fe-ZIF-SiO 2 , TEM see figure 1 (b)).

...

Embodiment 2

[0067] ① 1mmol (290.79mg) of nickel nitrate, 4mmol (1.19g) of zinc nitrate, and 32mmol (2.63g) of dimethylimidazole were weighed according to the corresponding molar ratio, and the metal salt nickel nitrate and zinc nitrate were dissolved in 500mL of methanol. Methimidazole was dissolved in 400 mL of methanol. Then the metal salt solution was slowly added to dimethylimidazole and stirred for 2h. Centrifuge to obtain the product, wash the product two to three times with methanol, and dry overnight to obtain the nickel-zinc bimetallic ZIF;

[0068] ②Dissolve 600mg of nickel-zinc bimetallic ZIF in 240mL of water, add cetyltrimethylammonium bromide solution 6mL (25mg / mL), Na 2 CO 3 Dissolve 10mL of the solution (10mg / mL) and 1.2mL of tetraethyl orthosilicate solution in 6mL of methanol, stir at 25°C for 0.5h; centrifuge, wash with ethanol, and dry to obtain the coating;

[0069] ③Calcinate the coating at high temperature, 1000°C, 3h, Ar 100sccm;

[0070] ④ After calcination, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com