Catalyst for preparing diol through hydration of epoxy compound and application of catalyst

An epoxy compound and catalyst technology, which is applied in the directions of organic compound/hydride/coordination complex catalyst, hydroxyl compound preparation, organic compound preparation, etc., can solve the problems of poor catalyst stability, cumbersome preparation steps and high cost, and achieves the The effect of easy separation, good selectivity and easy preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

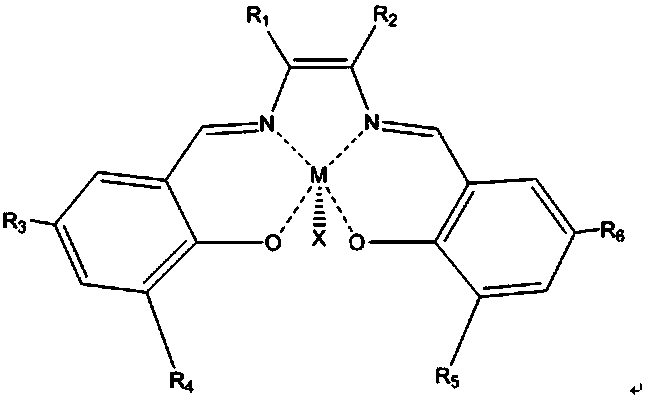

Method used

Image

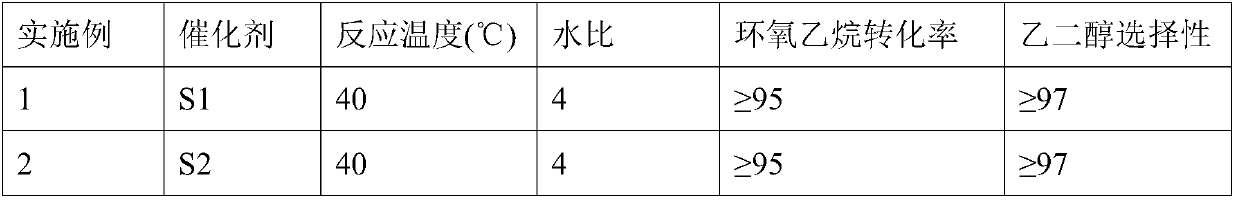

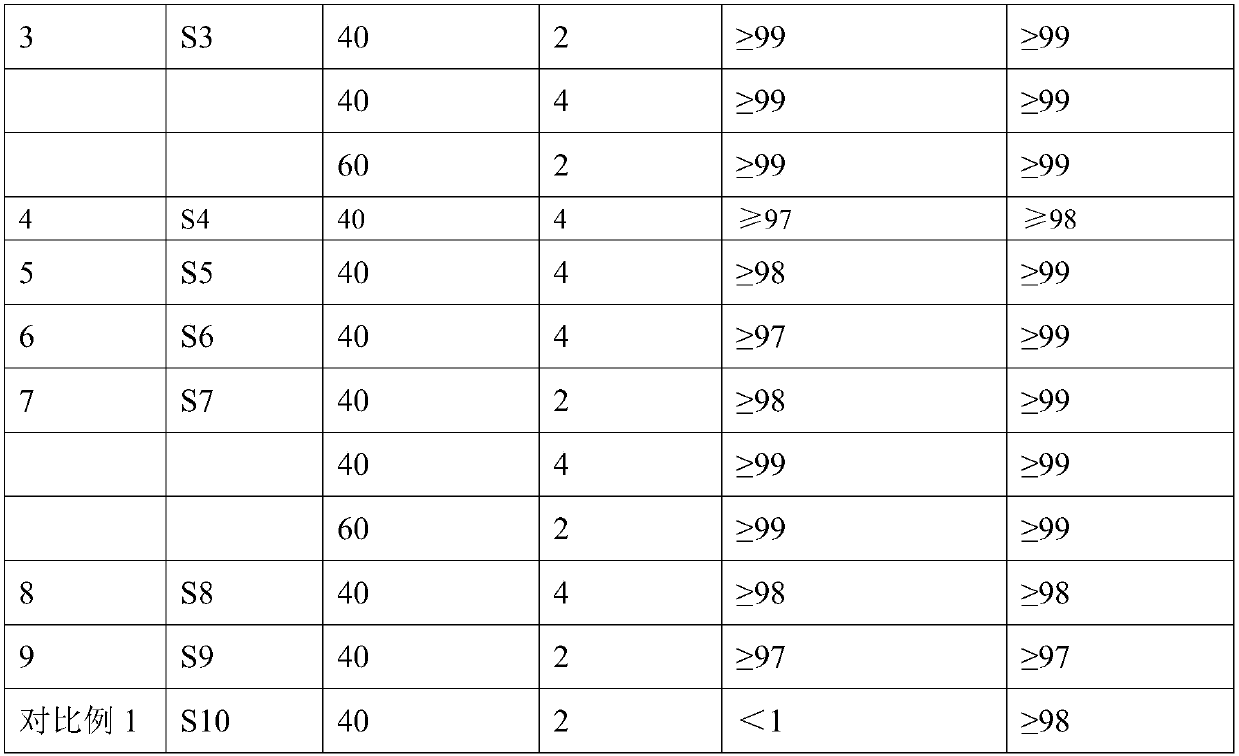

Examples

Embodiment 1

[0037] The preparation of catalyst in the present invention.

[0038]Mix 1g of sodium dodecylbenzenesulfonate with 0.27g of tert-butyl methacrylate, 0.28g of n-butyl methacrylate, 0.33g of ethylene glycol dimethacrylate, 59mg of glucose pentaacetate and 20mg of peroxide Dissolve lauroyl in 1ml of chloroform to obtain a mixed solution; mix 1g of cetyltrimethyl-p-toluenesulfonium ammonium with 0.27g of tert-butyl methacrylate, 0.28g of n-butyl methacrylate, 0.33g of dimethyl Ethylene glycol acrylate, 59 mg of glucose pentaacetate and 25 mg of 4,4'-methylenebis(N,N-dimethylaniline) were dissolved in 1 ml of chloroform to obtain a mixed solution. After the solvent in the two mixed liquids was evaporated and the mixture was obtained, the mixture was dissolved in 100ml of 10% Co(Salen)-OTS chloroform solution respectively, and the solution containing sodium dodecylbenzenesulfonate and the solution containing hexadecyl The trimethyl-p-toluenesulfonium ammonium solution was mixed and...

Embodiment 2

[0040] Mix 1g of sodium dodecylbenzenesulfonate with 0.27g of tert-butyl methacrylate, 0.28g of n-butyl methacrylate, 0.33g of ethylene glycol dimethacrylate, 59mg of glucose pentaacetate and 20mg of peroxide Dissolve lauroyl in 1ml of chloroform to obtain a mixed solution; mix 1g of cetyltrimethyl-p-toluenesulfonium ammonium with 0.27g of tert-butyl methacrylate, 0.28g of n-butyl methacrylate, 0.33g of dimethyl Ethylene glycol acrylate, 59 mg of glucose pentaacetate and 25 mg of 4,4'-methylenebis(N,N-dimethylaniline) were dissolved in 1 ml of chloroform to obtain a mixed solution. After the solvent in the two mixed liquids was evaporated, the solid phase was obtained and dissolved in 100ml of chloroform solution containing 20% Co(Salen)-OTS respectively. The solution containing sodium dodecylbenzenesulfonate and the solution containing cetyl The alkyl trimethyl ammonium p-toluenesulfonate solution was mixed and stirred at a volume ratio of 4, and reacted at 40°C under a nit...

Embodiment 3

[0042] Mix 1g of sodium dodecylbenzenesulfonate with 0.27g of tert-butyl methacrylate, 0.28g of n-butyl methacrylate, 0.33g of ethylene glycol dimethacrylate, 59mg of glucose pentaacetate and 20mg of peroxide Dissolve lauroyl in 1ml of chloroform to obtain a mixed solution; mix 1g of cetyltrimethyl-p-toluenesulfonium ammonium with 0.27g of tert-butyl methacrylate, 0.28g of n-butyl methacrylate, 0.33g of dimethyl Ethylene glycol acrylate, 59 mg of glucose pentaacetate and 25 mg of 4,4'-methylenebis(N,N-dimethylaniline) were dissolved in 1 ml of chloroform to obtain a mixed solution. After the solvent in the two mixed liquids was evaporated, the solid phase was obtained and then dissolved in 100ml of 30% Co(Salen)-OTS chloroform solution, and the solution containing sodium dodecylbenzenesulfonate and the solution containing cetyl The alkyl trimethyl ammonium p-toluenesulfonate solution was mixed and stirred at a volume ratio of 4, and reacted at 40°C under a nitrogen atmosphere....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com