A kind of antibacterial regenerated polyester fiber interlining and its production process

A technology of recycled polyester and production process, which is applied in the textile field, can solve the problems of increasing antibacterial property, limited antibacterial durability, and poor durability, and achieve the effects of reducing tension fluctuations, improving antibacterial performance, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

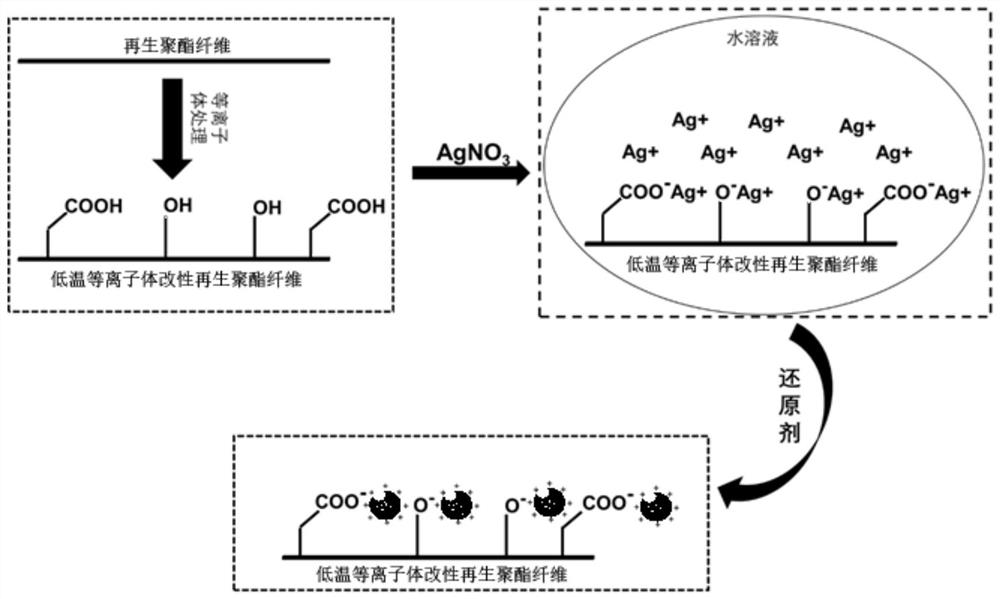

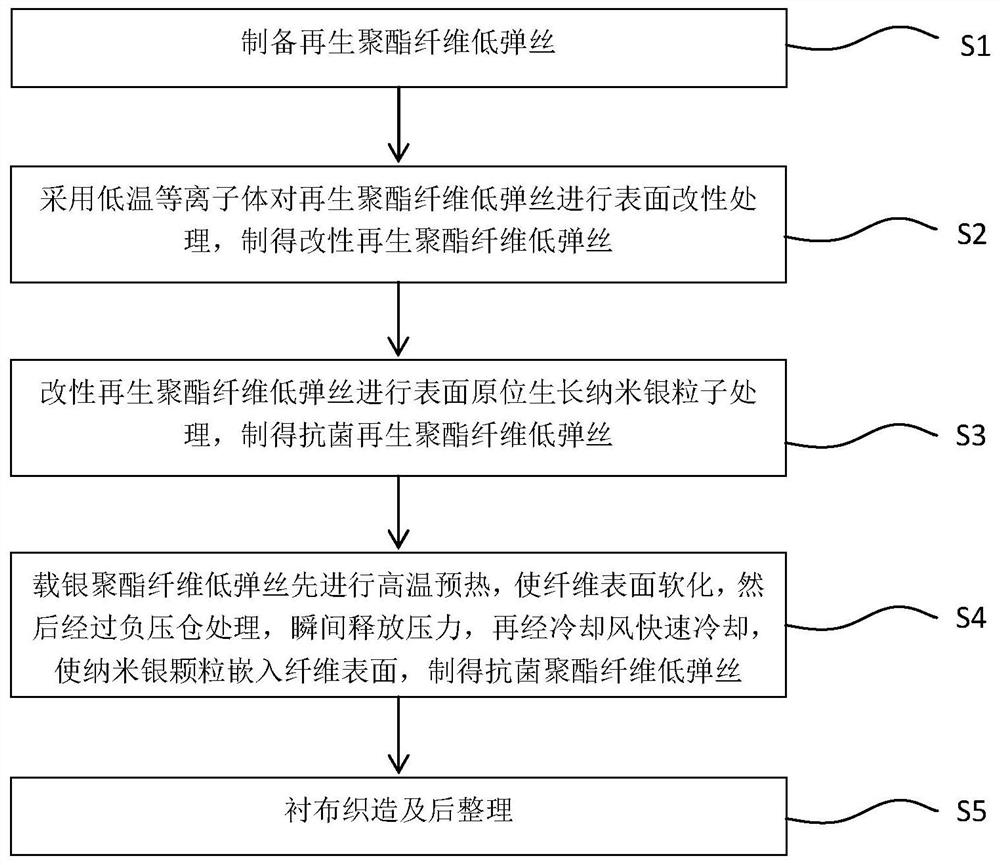

[0063] like figure 2 As shown, a production process of an antibacterial regenerated polyester fiber interlining includes the following steps:

[0064] S1, prepare regenerated polyester fiber low elastic yarn, adopt the method of physical regeneration to prepare regenerated polyester fiber low elastic yarn.

[0065] The preparation of recycled polyester fiber low elastic yarn includes the following steps:

[0066] S11. Sorting, crushing and cleaning waste PET bottles to obtain clean PET bottle flakes;

[0067] S12. Dry the polyester bottle flakes after cleaning, and then melt and filter to obtain a spinning solution;

[0068] S13. Spinning the spinning solution of step S12 to obtain regenerated polyester fibers.

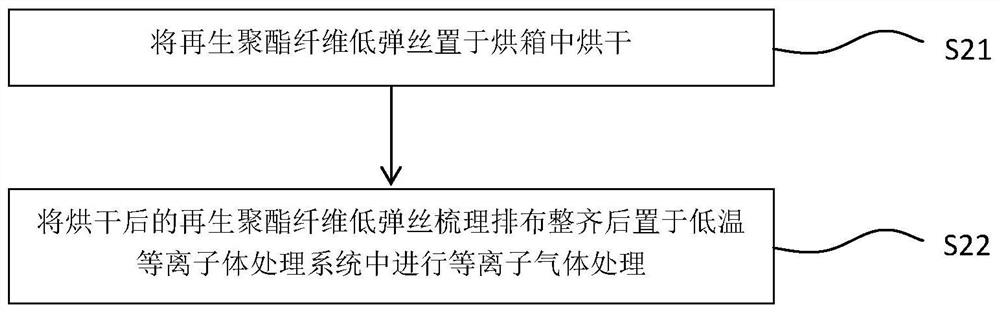

[0069] S2, using low temperature plasma to carry out surface modification treatment on the regenerated polyester fiber low elastic yarn, the fineness of the regenerated polyester fiber low elastic yarn is 15D, to prepare the modified regenerated polyester fiber lo...

Embodiment 2

[0090] like figure 2 As shown, a production process of an antibacterial regenerated polyester fiber interlining includes the following steps:

[0091] S1. Prepare regenerated polyester fiber low elastic yarn, and adopt chemical regeneration method to prepare regenerated polyester fiber low elastic yarn.

[0092] The preparation of recycled polyester fiber low elastic yarn includes the following steps:

[0093] S11. Sorting, crushing and cleaning waste PET bottles to obtain clean PET bottle flakes;

[0094] S12. Depolymerize the polyester bottle flakes after cleaning into polyester monomers by chemical reagents, and then polymerize them into high polymers to obtain spinning solution;

[0095] S13. The spinning solution of step S12 is subjected to high-pressure spinning to obtain regenerated polyester fibers.

[0096] S2, using low temperature plasma to carry out surface modification treatment on the regenerated polyester fiber low elastic yarn, the fineness of the regenerat...

Embodiment 3

[0116] like figure 2 As shown, a production process of an antibacterial regenerated polyester fiber interlining includes the following steps:

[0117] S1. Prepare regenerated polyester fiber low elastic yarn, and adopt chemical regeneration method to prepare regenerated polyester fiber low elastic yarn.

[0118] The preparation of recycled polyester fiber low elastic yarn includes the following steps:

[0119] S11. Sorting, crushing and cleaning of waste polyester waste silk;

[0120] S12. First depolymerize polyester waste silk after cleaning into polyester monomer by chemical reagent, and then polymerize into high polymer to obtain spinning solution;

[0121] S13. The spinning solution of step S12 is subjected to high-pressure spinning to obtain regenerated polyester fibers.

[0122] S2, using low-temperature plasma to carry out surface modification treatment on the regenerated polyester fiber low elastic yarn, the fineness of the regenerated polyester fiber low elastic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com