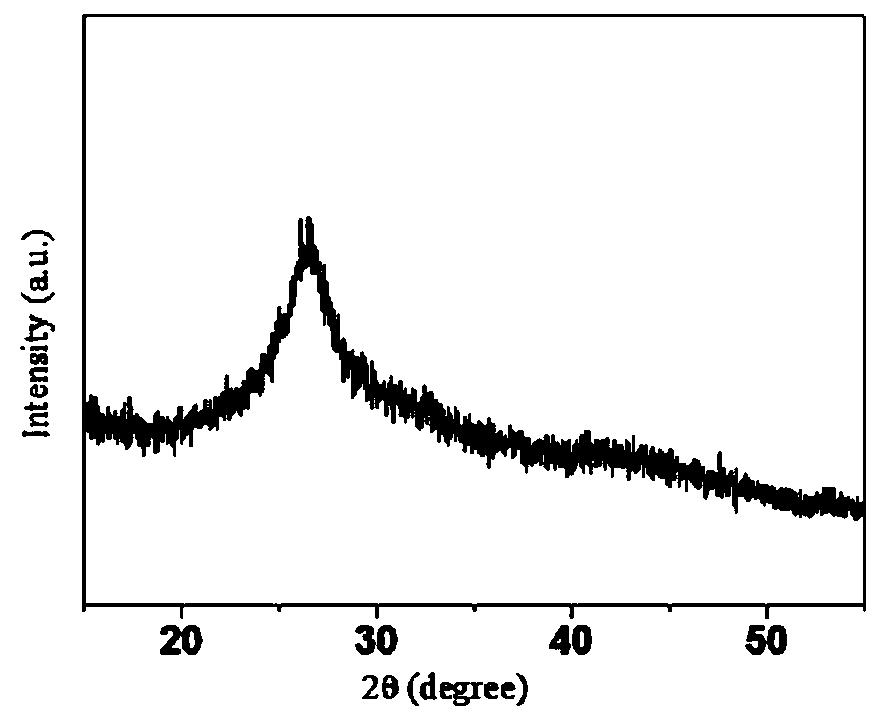

Highly-efficient preparation method for strong-fluorescence graphene quantum dot

A technology of graphene quantum dots and fluorescence, which is applied in the field of nano-fluorescent materials, can solve the problems of complex synthesis mechanism, harsh reaction conditions, and low synthesis yield, and achieve the effect of simple synthesis operation process, wide process window, and mild reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

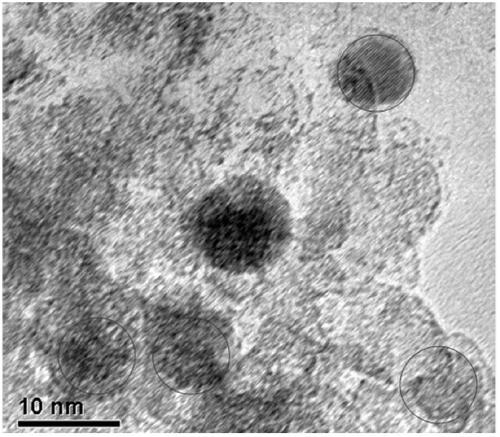

Embodiment 1

[0026] Weigh 40g of pyrene and put it into a 5L water-bath reactor, then add 3.2L of concentrated nitric acid with a concentration of 67wt%, slowly adjust the stirring speed to 150r / min, and set the temperature of the water bath at 60-80°C to make the reaction solution react at a constant temperature in a swirl state After cooling to room temperature for 10-24 hours, add 5-10 times the volume of deionized water to dilute, then perform suction filtration, rinse and dry to obtain about 64.5 g of surface nitro-functionalized intermediate product 1,3,6-trinitropyrene. Using ethanol as a solvent, measure 20ml of hydrazine hydrate and 980ml of ethanol to prepare an alkaline solution with a concentration of 2% by volume, then weigh 5g of 1,3,6-trinitropyrene solid and disperse it in the solution, and ultrasonicate under the condition of power 300W Pulverize for 1 hour to obtain a 1,3,6-trinitropyrene suspension with a concentration of 5 mg / ml. The above suspension was transferred to ...

Embodiment 2

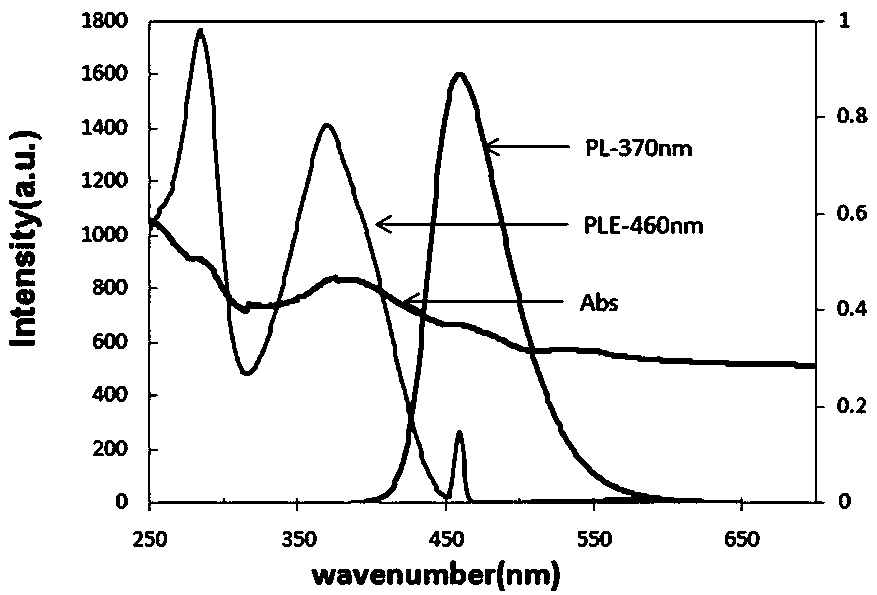

[0029] Configure 980ml of mixed solvents with a volume ratio of pure water and ethanol of 1:1, then add 20ml of hydrazine hydrate to configure an alkaline solution with a volume percentage concentration of 2%, then weigh 5g of the 1,3,6-trinitrogen prepared in Example 1 The pyrene solid was dispersed in the solution and ultrasonically pulverized for 1 hour at a power of 300W to obtain a suspension with a 1,3,6-trinitropyrene concentration of 5 mg / ml. The above suspension was transferred to a 5L high-pressure polytetrafluoroethylene reactor, sealed, and hydrothermally reacted in an oven at 200°C for 10 hours. After cooling, a tan solution with a graphene quantum dot content of about 1.45g was obtained. After the reaction, the solution was suction-filtered, and 5ml of the filtrate sample was taken for a fluorescence comparison test, and the remaining solution was dried to obtain graphene quantum dot powder.

[0030] The parameters of the fluorescence spectrometer were fixed, and...

Embodiment 3

[0032] Using ethanol as a solvent, measure 20ml of hydrazine hydrate and 980ml of ethanol to configure an alkaline solution with a concentration of 2% by volume, then weigh 15g of the 1,3,6-trinitropyrene solid prepared in Example 1 and disperse it in the solution Ultrasonic pulverization for 1 hour under the condition of power 300W to obtain a suspension with a concentration of 15 mg / ml of 1,3,6-trinitropyrene. Transfer the suspension to a 5L high-pressure polytetrafluoroethylene reactor, seal it, and react it hydrothermally in an oven at 200°C for 10 hours. After cooling, the content of graphene quantum dots is about 8.7g. volume mean) black solution. After the reaction, the solution was suction-filtered, and 5ml of the filtrate sample was taken for a fluorescence comparison test, and the remaining solution was dried to obtain graphene quantum dot powder.

[0033] The parameters of the fluorescence spectrometer were fixed, and it was found through testing that the fluoresce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com