Hydrogen-reduced thin-layer titanium carbide loaded cuprous oxide photo-cathode material for photoelectrolysis of water and preparation method for photo-cathode material

A technology of cuprous oxide light and cuprous oxide, which is applied in the direction of electrodes, electrolytic processes, electrolytic components, etc., can solve the problems of application limitations, poor stability, photocorrosion, etc., easy to achieve conditions, simple preparation process, and improved photoelectrochemical performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

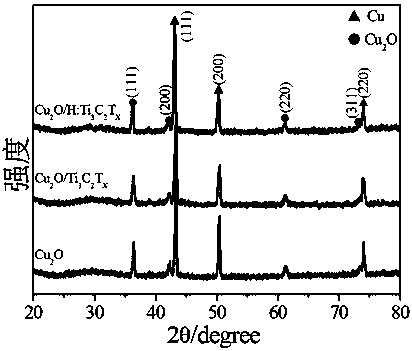

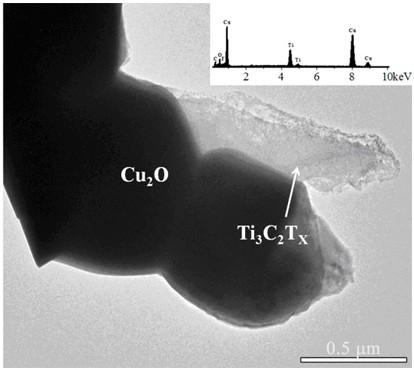

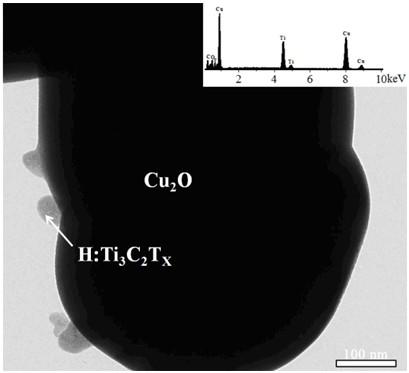

[0033] Cu 2 O / Ti 3 C 2 T x and Cu 2 O / H:Ti 3 C 2 T x Preparation of composite electrodes

[0034] (1) Put titanium aluminum carbide in hydrofluoric acid and stir at room temperature for 20 h, wash until neutral, filter with suction, and dry in vacuum;

[0035](2) Add the substance obtained in step (1) into the dimethyl sulfoxide solution and stir for 20 h, wash to remove excess dimethyl sulfoxide, then sonicate under an argon atmosphere, centrifuge and dry to obtain a thin layer of titanium carbide, namely Ti 3 C 2 T x ;

[0036] (3) React the thin-layer titanium carbide obtained in step (2) in a reducing atmosphere of hydrogen at 400°C for 30 min to obtain reduced thin-layer titanium carbide, namely H:Ti 3 C 2 T x ;

[0037] (4) Stir and disperse potassium hydroxide and ammonium persulfate in water evenly to obtain an aqueous solution of 0.23 mol / L potassium hydroxide and 1.47 mol / L ammonium persulfate, then place the copper sheet in the solution, react for 5 m...

Embodiment 2

[0042] Cu 2 O / Ti 3 C 2 T x and Cu 2 O / H:Ti 3 C 2 T x Preparation of composite electrodes

[0043] (1) Put titanium silicon carbide in hydrofluoric acid and stir at room temperature for 24 h, wash until neutral, filter with suction, and dry in vacuum;

[0044] (2) Add the substance obtained in step (1) into the dimethyl sulfoxide solution and stir for 24 h, wash to remove excess dimethyl sulfoxide, then sonicate under an argon atmosphere, centrifuge and dry to obtain a thin layer of titanium carbide, namely Ti 3 C 2 T x ;

[0045] (3) React the thin-layer titanium carbide obtained in step (2) in a reducing atmosphere of hydrogen at 500°C for 30 min to obtain reduced thin-layer titanium carbide, namely H:Ti 3 C 2 T x ;

[0046] (4) Copper sheet is used as working electrode, platinum sheet is used as counter electrode, 3 mol / L sodium hydroxide solution is used as electrolyte, and the current is 5 mA / cm 2 After reacting for 10 min, the copper sheet was rinsed with ...

Embodiment 3

[0051] Cu 2 O / Ti 3 C 2 T x and Cu 2 O / H:Ti 3 C 2 T x Preparation of composite electrodes

[0052] (1) Put titanium aluminum carbide in hydrofluoric acid and stir at room temperature for 24 h, wash until neutral, filter with suction, and dry in vacuum;

[0053] (2) Add the substance obtained in step (1) into the dimethyl sulfoxide solution and stir for 24 h, wash to remove excess dimethyl sulfoxide, then sonicate under an argon atmosphere, centrifuge and dry to obtain a thin layer of titanium carbide, namely Ti 3 C 2 T x ;

[0054] (3) React the thin-layer titanium carbide obtained in step (2) in a reducing atmosphere of hydrogen at 600°C for 30 min to obtain reduced thin-layer titanium carbide, namely H:Ti 3 C 2 T x ;

[0055] (4) Add 3 mg / mL lactic acid solution to 0.3 mg / mL copper nitrate solution as the electrolyte, adjust the pH to be alkaline, use FTO conductive glass as the substrate, platinum sheet as the counter electrode, and silver / silver chloride elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com