A carrier, catalyst and preparation method for hydrodesulfurization

A technology of hydrodesulfurization and catalyst support, which is applied in the direction of catalyst activation/preparation, catalyst support, chemical instruments and methods, etc. It can solve the problems of poor metal tolerance and single function, and achieve enhanced mechanical strength, good activity, and high metal and the effect of nitrogen removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Weigh 25 grams of activated carbon with a particle size of 6 microns, spray and impregnate the above-mentioned activated carbon with 7.5 mL of ammonium hydrogen phosphate solution with a mass concentration of 28%, and mix the activated carbon with 260 grams of pseudoboehmite dry rubber powder (Wenzhou Jing Crystal Alumina Co., Ltd.), 8 grams of Squatia powder, mixed evenly, adding an appropriate amount of 1.5% acetic acid aqueous solution, kneaded, extruded, and dried at 100 ° C for 6 hours, and dried at 700 °C in an air atmosphere ℃ for 5 hours to obtain the alumina carrier intermediate ZA1.

[0050] Weigh 100 grams of the above-mentioned alumina carrier intermediate ZA1, place it in 500 grams of ammonium bicarbonate solution, the mass concentration of the ammonium bicarbonate solution is 14% aqueous solution, transfer the mixed material into an autoclave and seal it, and heat it at 15°C Raise the temperature to 100°C at a speed of 10°C / min and keep the temperature for...

Embodiment 2

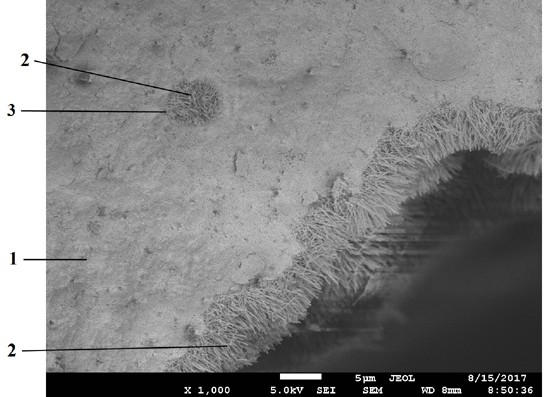

[0052] Same as Example 1, except that the activated carbon was changed to charcoal with a particle size of 4 microns, and the amount of charcoal added was 29 grams to obtain the alumina carrier intermediate ZA2. The quality of ammonium bicarbonate solution is 600 grams, and the mass concentration of ammonium bicarbonate solution is 17.5%. The sealing pretreatment temperature was 90°C, the treatment time was 2 hours, the heat treatment temperature was 110°C, and the treatment time was 8 hours, and the alumina carrier A2 was prepared. The properties of the carrier are shown in Table 1. P in the alumina carrier A2 2 o 5 The content is 1.5wt%, the length of the rod-shaped alumina in the micron-sized pores is mainly 1-3.5 μm, the length of the rod-shaped alumina on the outer surface of the main alumina is mainly 3-8 μm, and the rod-shaped alumina on the outer surface of the main alumina The coverage rate of alumina accounts for about 78%, and the coverage rate of rod-shaped alumi...

Embodiment 3

[0054] The same as in Example 1, except that the activated carbon was changed to wood chips with a particle size of 7 microns, and the amount of wood chips added was 21 grams to obtain the alumina carrier intermediate ZA3. The quality of ammonium bicarbonate solution is 300 grams, and the mass concentration of ammonium bicarbonate solution is 20%. The heating rate before sealing pretreatment was 11°C / min, the heating rate after sealing pretreatment was 5°C / min, the heat treatment temperature was 150°C, and the treatment time was 4 hours to prepare alumina carrier A3. The properties of the carrier are shown in the table 1. P in the alumina carrier A3 2 o 5 The content is 0.8wt%, the length of the rod-shaped alumina in the micron-sized pores is mainly 2.0-6.0 μm, the length of the rod-shaped alumina on the outer surface of the main alumina is mainly 3-8 μm, and the rod-shaped alumina on the outer surface of the main alumina The coverage rate of alumina accounts for about 83%,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com