Preparation method for synthesizing spherical-shell-type stable metal nano catalyst by one-pot method

A metal nano-catalyst technology, applied in the field of catalytic chemistry, to achieve the effects of small metal particle size, uniform distribution, and improved utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

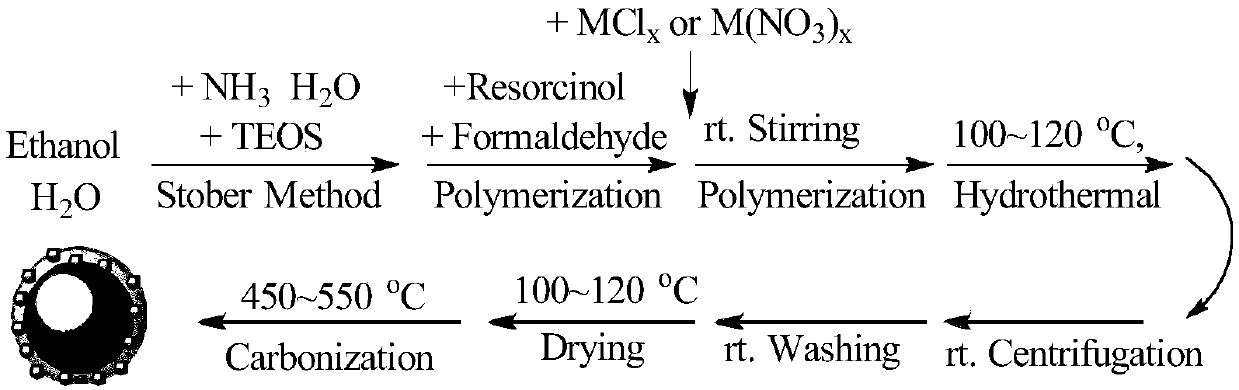

Method used

Image

Examples

Embodiment 1

[0031] The preparation of embodiment 1 Ru-SiRF catalyst

[0032] Add 75mL of ethanol-water system (volume ratio of ethanol to water: 2:1) into a 250mL round-bottomed flask, place it on a magnetic stirrer and mix evenly, add 3mL of ammonia water (NH 3 ·H 2 O, 25%~28%), after stirring vigorously for 10min, add 2.8mL TEOS (98%) dropwise, continue stirring for 10min, then add 0.4g resorcinol (99.8%), after stirring for 10min, add 0.56mL formaldehyde dropwise ( HCHO, 37% to 40%). After continuing to stir for 10-30min, add RuCl containing 1mmol Ru 3 Metal salt, after stirring at room temperature for 24 hours, transfer the reaction mixture into a 100mL hydrothermal kettle and seal it, then place it in an oven at 100°C for 24 hours of hydrothermal reaction and take it out. After cooling to room temperature, transfer the hydrothermal reaction solution to a centrifuge tube After centrifuging at 10,000rpm for 3min in a high-speed refrigerated centrifuge, the lower precipitate was wash...

Embodiment 2

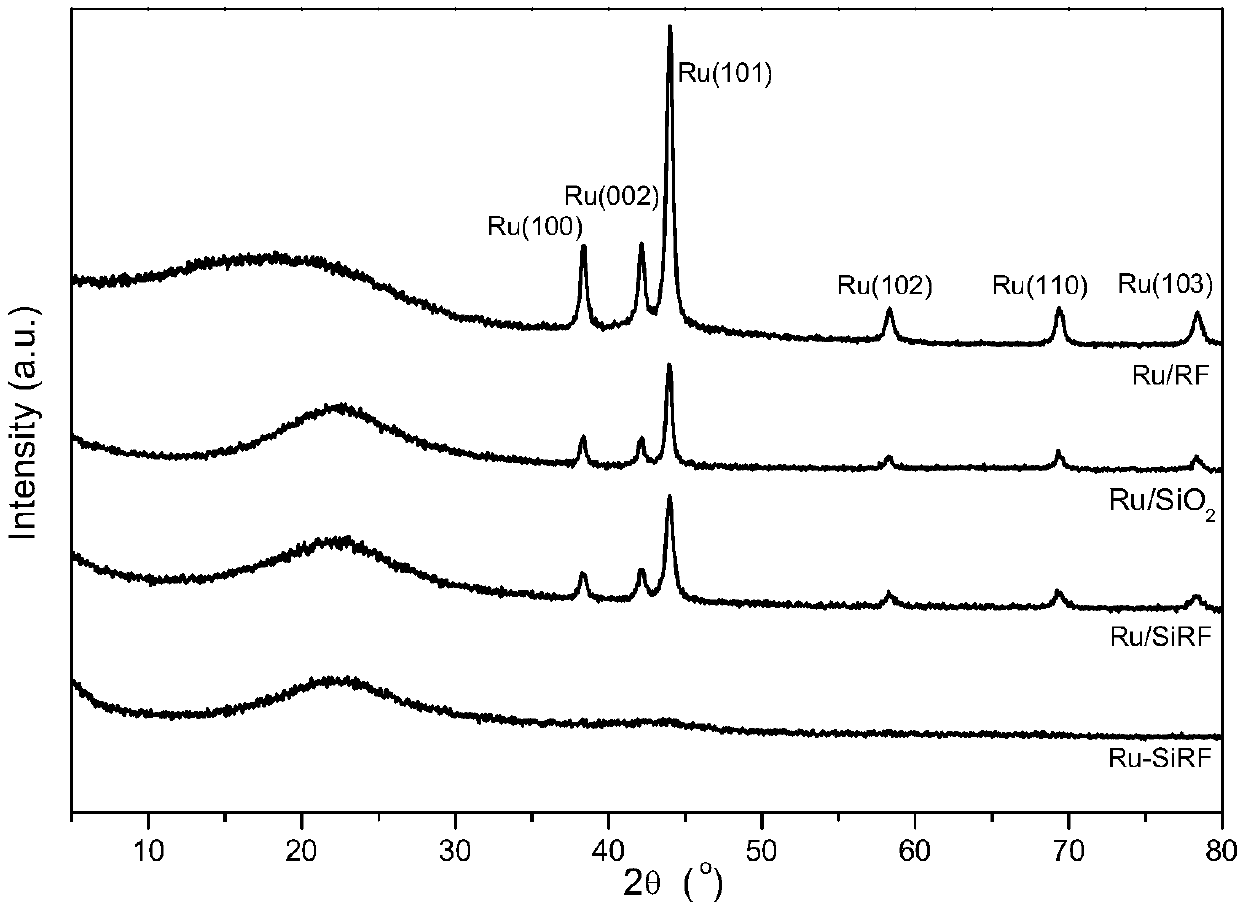

[0035] Example 2 Ru-SiRF and Ru / SiO 2 , XRD characterization of Ru / RF, Ru / SiRF catalysts, the characterization results are as follows figure 2 As shown, the results show that the metal nanocatalyst prepared by this method has the characteristics of small metal nanoparticles and high dispersion compared with the catalyst prepared by the impregnation method.

Embodiment 3

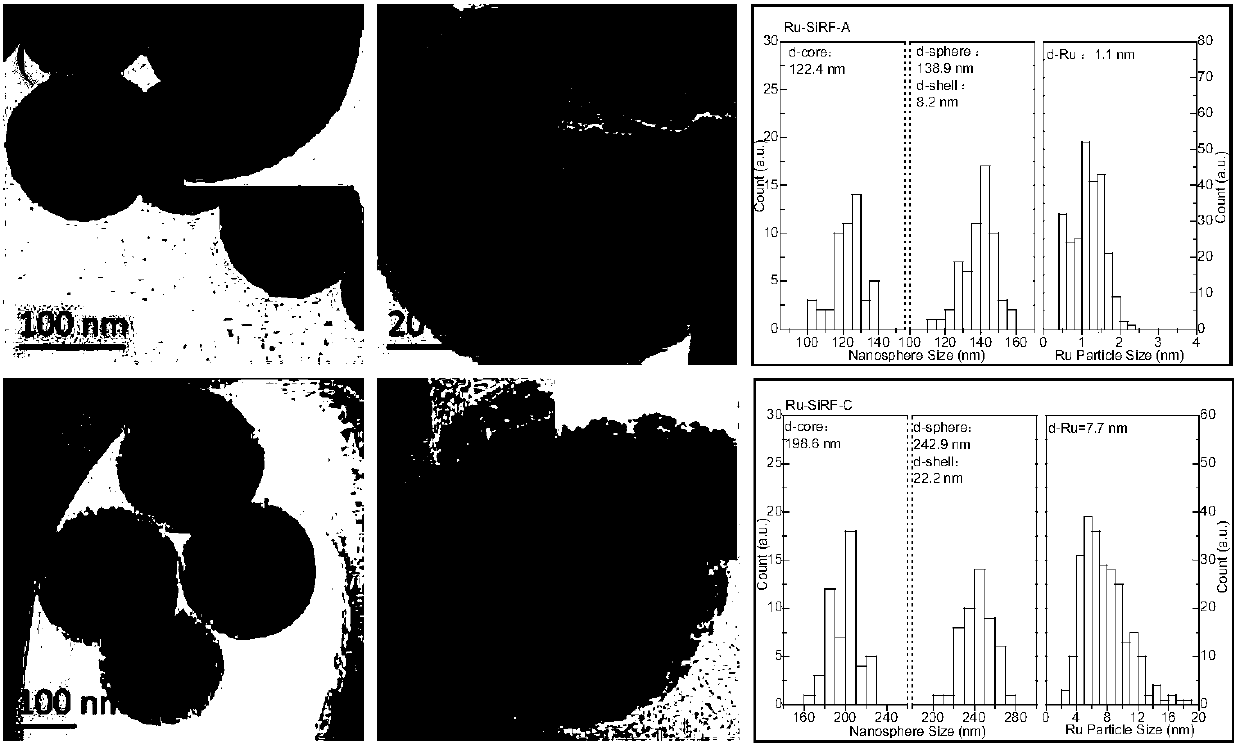

[0036] The TEM characterization of embodiment 3 Ru-SiRF and Ru / SiRF catalyst, the characterization result is as follows image 3 As shown, the results show that the metal nanocatalyst prepared by this method has the characteristics of uniform dispersion of metal nanoparticles and small particle size.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com