Red fluorescence polymer and red fluorescence powder, preparation methods and applications thereof

A technology of red light fluorescent powder and red light fluorescence is applied in the direction of conjugated synthetic polymer rayon, single-component synthetic polymer rayon, chemical instruments and methods, etc., and can solve the problem of non-conjugated polymer fluorescent agent production. In order to solve the problems of low yield, single color of non-conjugated polymers, and high price of organic dyes, it achieves the effects of good water solubility, simple and easy preparation method, and low biological toxicity and environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

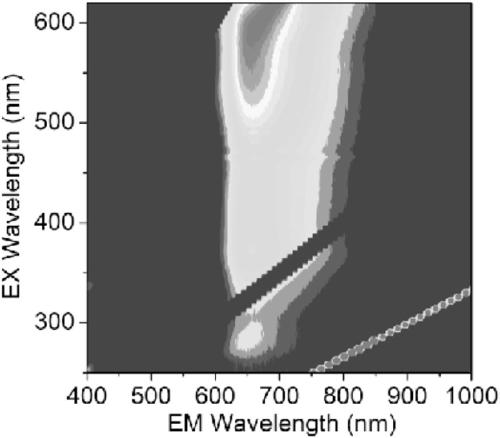

[0105] Weigh 19.2g of maleic anhydride-vinyl acetate linear alternating copolymer (MVL) into 200mL of ethanol solution, stir to disperse; Weigh 4.8g of sodium hydroxide into 200mL of deionized water to dissolve; Dissolve MVL’s ethanol The dispersion was added dropwise to the aqueous solution of sodium hydroxide while stirring until fully mixed. After that, it was treated in a 40°C constant temperature oven for 48 hours to remove the ethanol in it to obtain an aqueous solution of a strong base modified polymer. The solid obtained after drying the aqueous solution at 65°C for 48 hours is heated in a constant temperature blast drying oven at 180°C until it becomes uniform red to obtain a red fluorescent polymer, which shows bright red fluorescence under ultraviolet light. Its three-dimensional fluorescence spectrum is as follows figure 1 As shown, its excitation range is between 300-640nm, that is, covering the full spectrum region from ultraviolet to yellow light, and its emissio...

Embodiment 2

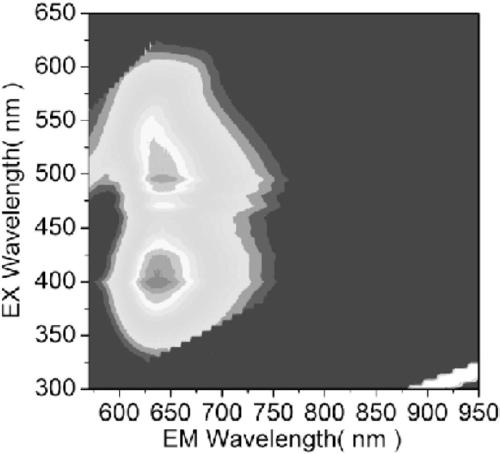

[0107] Weigh 19.2g of maleic anhydride-vinyl acetate linear alternating copolymer (MVL) into 500mL of ethanol solution, stir to disperse; Weigh 2.88g of lithium hydroxide into 500mL of deionized water to dissolve; Dissolve MVL in ethanol The dispersion was added dropwise to the aqueous solution of lithium hydroxide while stirring until fully mixed. After that, it was treated in a 40°C constant temperature oven for 48 hours to remove the ethanol in it to obtain an aqueous solution of a strong base modified polymer. The solid obtained after drying the aqueous solution at 65°C for 48 hours is heated in a constant temperature blast drying oven at 180°C until it becomes uniform red to obtain a red fluorescent polymer, which shows bright red fluorescence under ultraviolet light. Its three-dimensional fluorescence spectrum is as follows figure 2 As shown, its excitation range is between 300-640nm, that is, covering the full spectrum region from ultraviolet to yellow light, and its em...

Embodiment 3

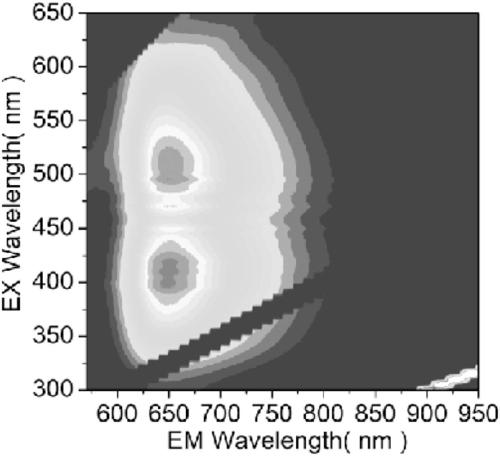

[0109] Weigh 19.2g of maleic anhydride-vinyl acetate linear alternating copolymer (MVL) into 150mL of ethanol solution, stir and disperse; Weigh 6.72g of potassium hydroxide into 100mL of deionized water to dissolve; Dissolve MVL’s ethanol The dispersion was added dropwise to the aqueous potassium hydroxide solution while stirring until fully mixed. After that, it was treated in a 40°C constant temperature oven for 48 hours to remove the ethanol in it to obtain an aqueous solution of a strong base modified polymer. The solid obtained after drying the aqueous solution at 65°C for 48 hours is heated in a constant temperature blast drying oven at 180°C until it becomes uniform red to obtain a red fluorescent polymer, which shows bright red fluorescence under ultraviolet light. Its three-dimensional fluorescence spectrum is as follows image 3 As shown, its excitation range is between 300-640nm, that is, covering the full spectrum region from ultraviolet to yellow light, and its em...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com