Single-component polyurethane bonding adhesive and preparation method thereof

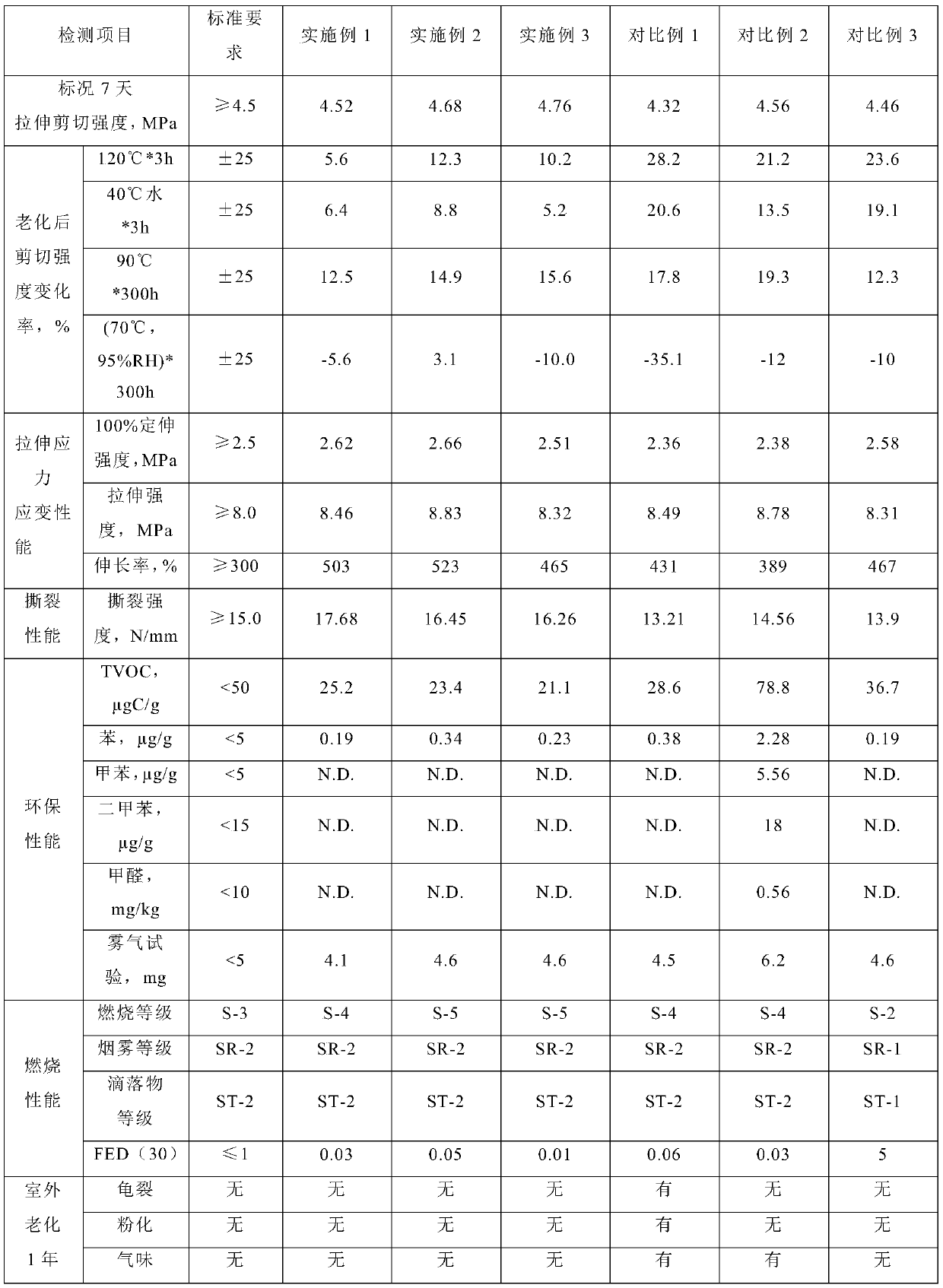

A technology of adhesive and polyurethane, which is applied in the field of adhesive, can solve problems such as cracking on the surface of the colloid, reduction of mechanical properties, pulverization, etc., and achieves good aging resistance, flame retardancy, excellent thixotropy, and extrudability good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] The first polyurethane prepolymer 300g, the second polyurethane prepolymer 70g, synthetic vegetable ester 150g, triisopropylphenyl phosphate 40g, 3-butyl-2-(1-ethylpentyl) oxazolidine 10g Add to the stirred tank, close the tank, vacuumize, and stir until the materials are evenly mixed;

[0073] Stirring was stopped, the vacuum valve was closed, the vacuum was vented with nitrogen, and 120 g of carbon black after dehydration and drying, 100 g of polyurethane grade calcium carbonate, 15 g of calcium oxide, and 18 g of fumed silica were added to the kettle, and stirred until uniform under vacuum;

[0074] Stop stirring, close the vacuum valve, release the vacuum with nitrogen, add 5 g of γ-(2,3-glycidoxy) propyltrimethoxysilane, 0.4 g of stannous octoate and 1.0 g of dimorphinyl diethyl ether In the kettle, vacuumize and stir until a one-component polyurethane adhesive is obtained, which is a black homogeneous fine paste, and the tank is used for equipment.

Embodiment 2

[0076] Add 350g of the first polyurethane prepolymer, 40g of the second polyurethane prepolymer, 70g of octyl epoxy stearate, 90g of phenyl sulfonate, 30g of tris(xylylene) phosphate, and 10g of methylbenzenesulfonyl isocyanate In the stirring kettle, close the lid of the kettle, vacuumize, and stir until the materials are evenly mixed;

[0077] Stop stirring, close the vacuum valve, release the vacuum with nitrogen, add 130g of carbon black, 80g of polyurethane grade kaolin, 25g of polyurethane grade calcium carbonate, 19g of calcium oxide, and 21g of polyamide wax into the kettle, vacuumize, and stir until uniform;

[0078] Stop stirring, close the vacuum valve, release the vacuum with nitrogen, add 5g of 3-mercaptopropyltrimethoxysilane, 0.5g of zinc isooctanoate, and 0.8g of triethylenediamine into the kettle, vacuumize and stir until one-component polyurethane is obtained Adhesive, which is a black homogeneous fine paste, used for tank equipment.

Embodiment 3

[0080] Add 300g of the first polyurethane prepolymer, 70g of the second polyurethane prepolymer, 156g of synthetic vegetable ester, 30g of triisopropylphenyl phosphate, 20g of aluminum hydroxide, and 12g of triethyl orthoformate into the stirring tank, close the tank Cover, vacuumize, and stir until the material is evenly mixed;

[0081] Stop stirring, close the vacuum valve, release the vacuum with nitrogen, add 120g of carbon black, 90g of polyurethane grade calcium carbonate, and 20g of polyurea into the kettle, vacuumize, and stir until uniform;

[0082] Stirring was stopped, the vacuum valve was closed, and the vacuum was released with nitrogen, and 5 g of γ-(2,3-epoxypropoxy)propyltrimethoxysilane, 0.4 g of bismuth naphthenate and 1.0 g of bismorphine diethyl ether were Add it into the kettle, vacuumize and stir until a one-component polyurethane adhesive is obtained, which is a black homogeneous fine paste, and can be used for equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com