Chitosan-oligosaccharide-modified self-carrying type carrier-free nasal cavity nano preparation brain-targeted delivery system and preparation method thereof

A nano-preparation and delivery system technology, applied in the field of biomedicine, can solve the problems of drugs that are difficult to cross the blood-brain barrier, low bioavailability, and poor druggability, and achieve the effects of small particle size, long circulation time, and high drug loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

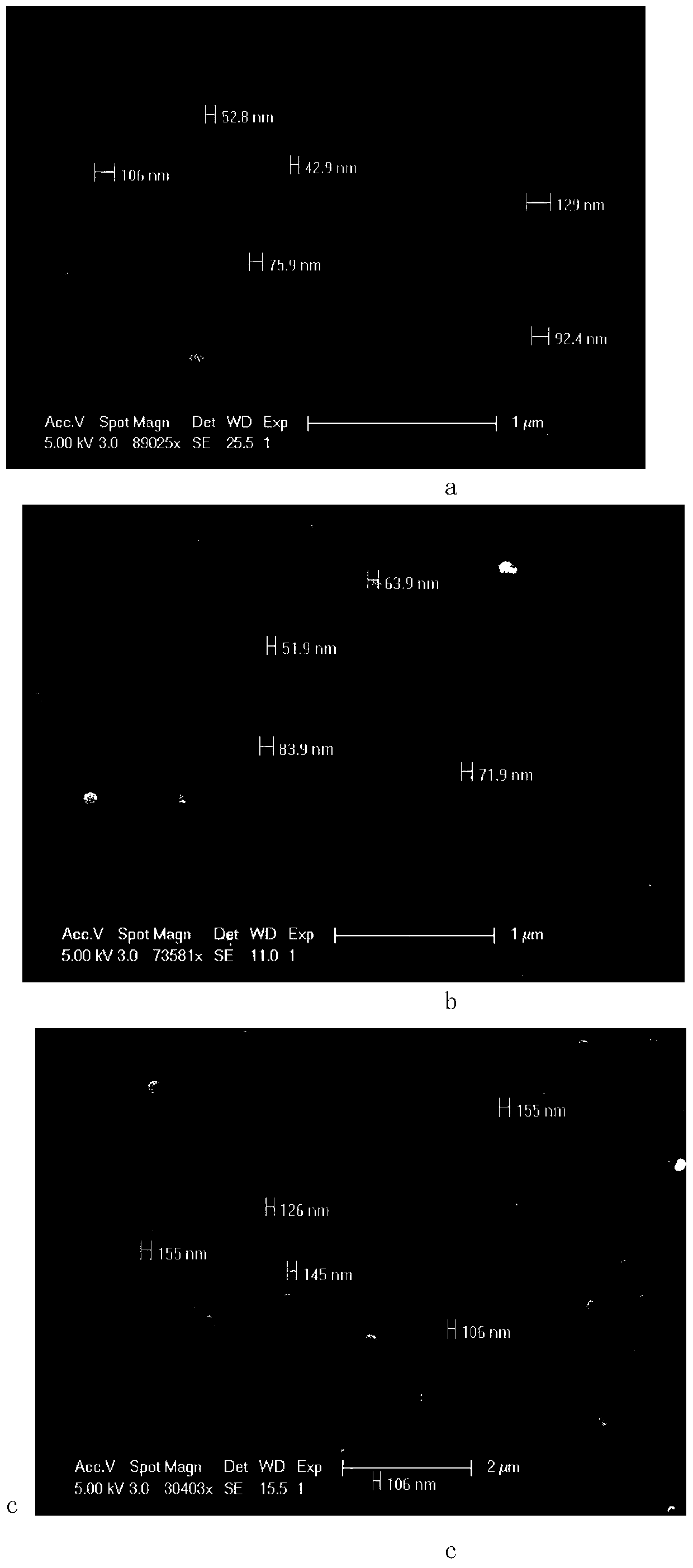

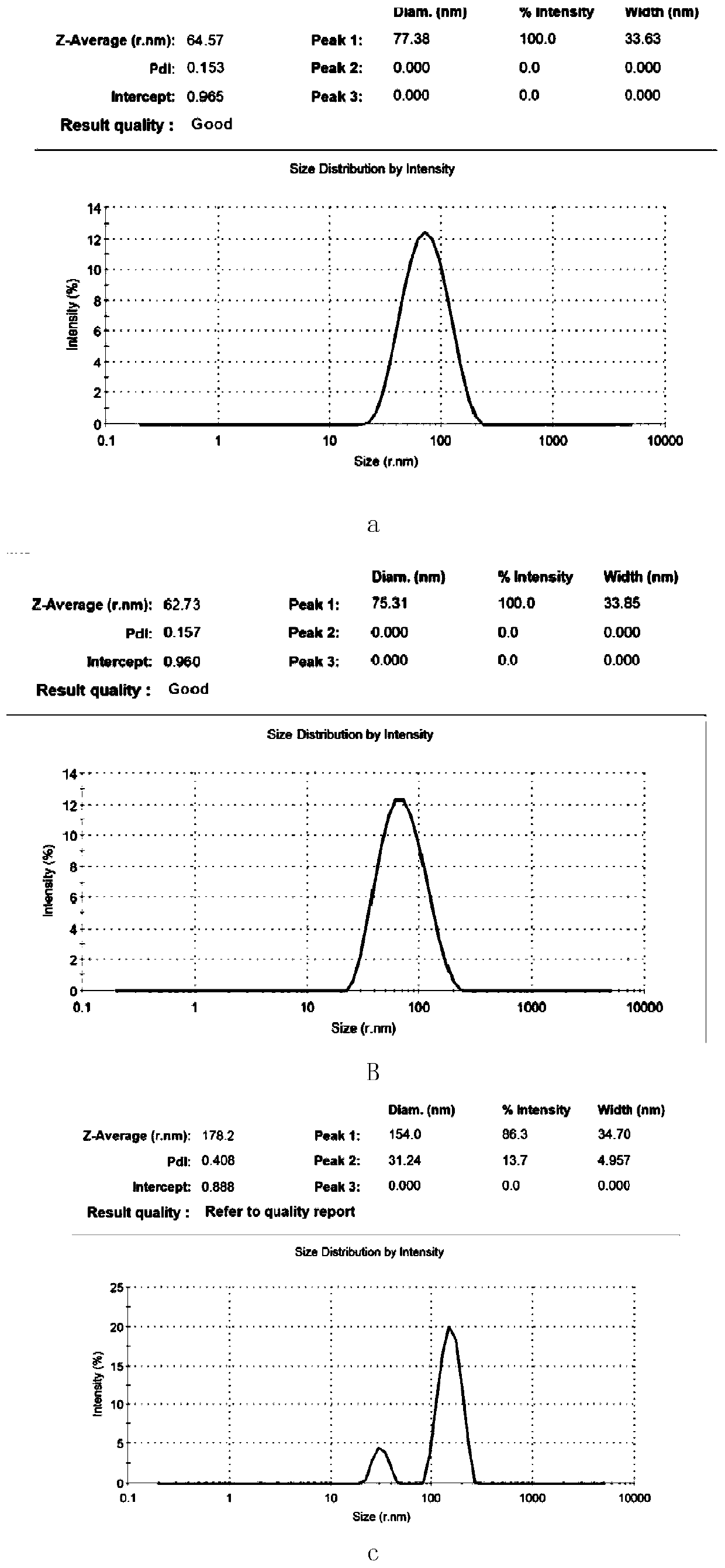

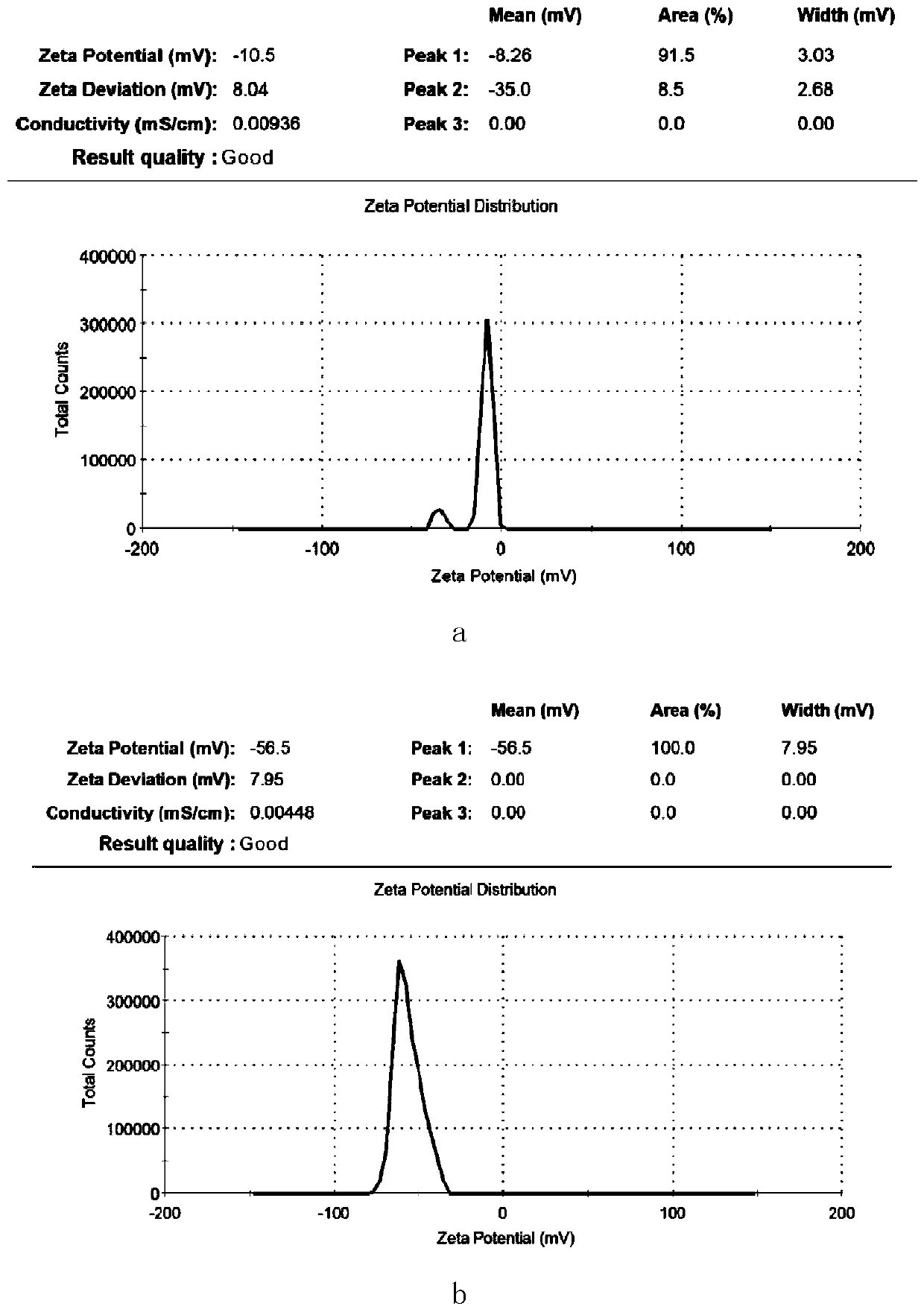

[0083] Embodiment 1: the preparation of curcumin nasal cavity nano preparation

[0084] The curcumin structure used in this implementation is as follows:

[0085]

[0086] Configuration contains 1.5mM concentration of curcumin drug molecules and 2mg / mL of polymaleic anhydride 18 carbene-polyethylene glycol-tetrahydrofuran solution 10mL, get 200 μL of the curcumin solution and add it dropwise to 4mL deionized water. Nitrogen blowing is supplemented at the same time, and the aqueous solution is vigorously stirred to remove the organic solvent. After stirring for 10 minutes, it is allowed to stand still to obtain a self-contained carrier-free curcumin nanoparticle suspoemulsion, which is freeze-dried to form a freeze-dried powder. Before use, redisperse the lyophilized powder in isotonic saline, add it dropwise into chitosan oligosaccharide (0.1w / v) saline solution, stir for 0.5h, and use physical adsorption for 1 hour to react with 10000 centrifuge at a speed of *g for 10 mi...

Embodiment 2

[0096] Embodiment 2: the preparation of curcumin analog M1 nasal cavity nano preparation

[0097] The curcumin analog M1 used in the present embodiment is the isomer mixture of the curcumin analog of the following structural formula:

[0098]

[0099] According to the applicant's computer simulation results, in the mixture, the higher the ratio of the cis isomer, the stronger the biological activity of the product. But in practice, the higher the product, the higher the yield of by-products.

[0100] In this embodiment, a method for obtaining an isomer product with a conversion rate of 30% is provided, the preparation method is simple, and no by-products are generated.

[0101] According to the hydrophobic nature of curcumin analogues, they are dissolved in good solvents and subjected to different radiation conditions, different degrees of isomer conversion can occur, and different ratios of cis-trans isomer mixtures can be obtained. Among them, the conversion rate of sun...

Embodiment 3

[0128] Example 3: M1 nasal cavity nano-preparation brain-targeted delivery system loaded with fluorescent probe TPAAQ

[0129] TPAAQ is a hydrophobic small molecule fluorescent probe excited at 473nm and emitted at 650nm, which can be used to monitor the fluorescence distribution of nanomaterials in vivo. Because it is also a small hydrophobic molecule, the preparation process of the M1 nanoparticle in Example 2 is similar, and the M1 nasal cavity nano-preparation loaded with TPAAQ can be obtained by the same method.

[0130] Prepare 5 mL of a tetrahydrofuran solution containing 1 mg / mL of M1 and 2 mg / mL of TPAAQ, mix well, take 200 μL of the M1 molecular solution, add it dropwise to 5 mL of deionized water, and blow with nitrogen to remove the organic solvent. After 10 minutes of magnetic stirring at 25°C, it was left to stand, and the M1 self-contained carrier-free nanoparticle suspoemulsion loaded with the fluorescent probe TPAAQ was obtained, and lyophilized to form a lyop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com