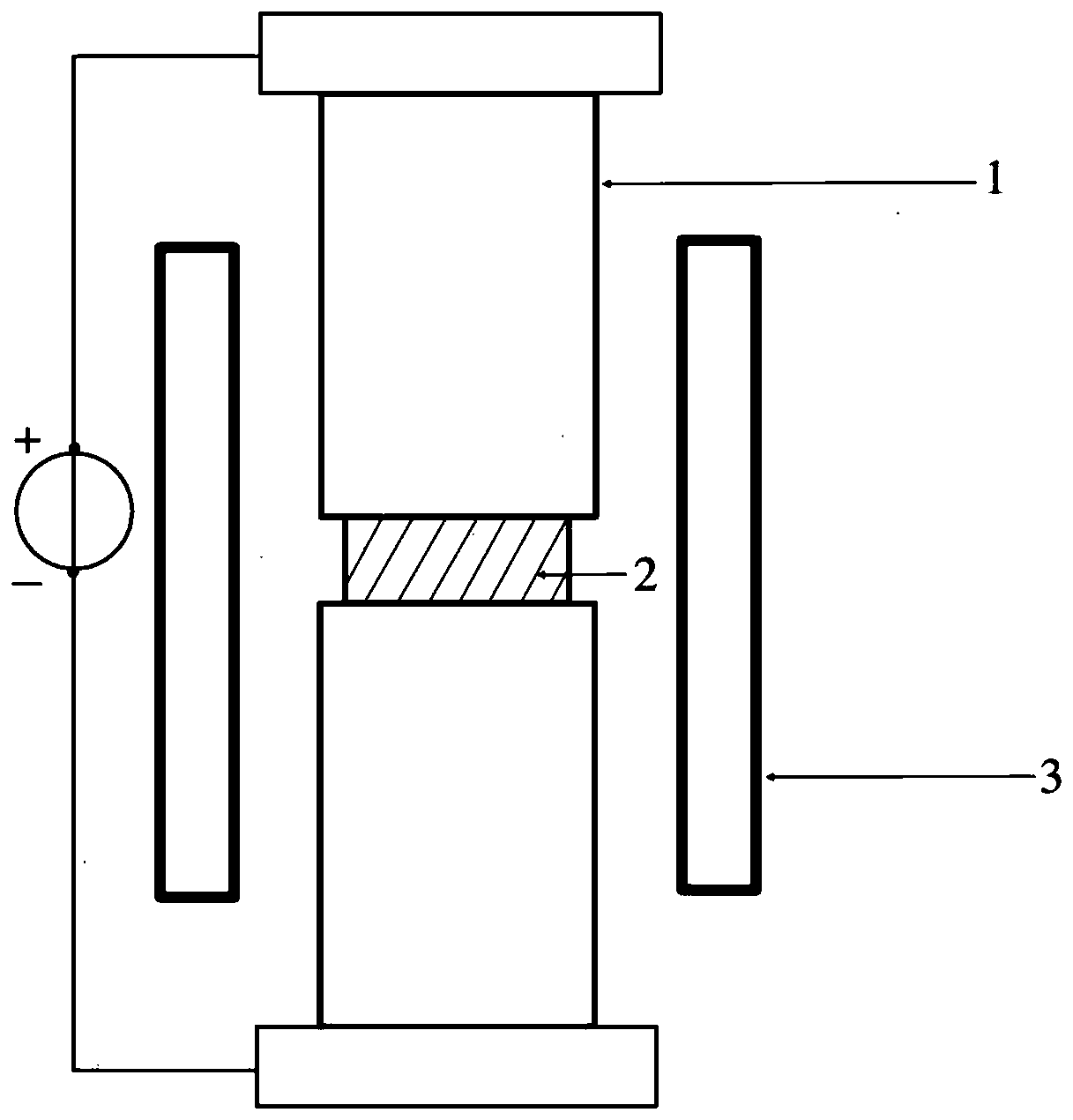

Electric field assisted quick sintering method of ultrafine-grained hafnium oxide ceramic

An electric field-assisted sintering and hafnium dioxide technology, which is applied in the field of electric field-assisted rapid sintering of ultra-fine grain hafnium dioxide ceramics, can solve the problems of long time, few people involved in hafnium dioxide ceramics, and high melting point, so as to improve the powder Conductivity, inhibition of grain growth, and uniform grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

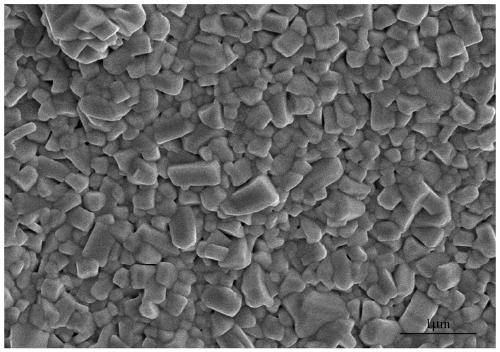

Embodiment 1

[0025] Weigh 1.4g of HfO 2 The powder is pressed at 100MPa into a green body with a thickness of Φ10mm and a thickness of 4.5mm. The sample is placed between two silicon-molybdenum rod electrodes, and the radiation heating element of the radiation heating equipment is used to heat the sample. After rising to 800°C, Start to enter the heat preservation stage, and at the same time, increase the voltage at both ends of the sample to 200V (the field strength is about 444.4V / cm), hold the heat for 10 minutes, and then increase the voltage to 250V (the field strength is about 555.6V / cm), heat and hold the pressure After 10 minutes, the voltage rises to 300V (the field strength is about 666.7V / cm), and after 10 minutes of heat preservation and pressure holding, the voltage rises to 360V (the field strength is about 800V / cm), and the current value is controlled to 5A. The terminal voltage and the power supply of the muffle furnace allowed the samples to cool down to room temperature n...

Embodiment 2

[0027] Weigh 30.5g of HfO 2 The powder is pressed at 200MPa into a green body with a diameter of Φ50mm and a thickness of 4.0mm. The sample is placed between two silicon-molybdenum rod electrodes, and the radiation heating element of the radiation heating equipment is used to heat the sample. After rising to 1300°C, Start to enter the heat preservation stage, and at the same time, increase the voltage at both ends of the sample to 200V (the field strength is about 500.0V / cm), hold the heat for 10 minutes, and then increase the voltage to 250V (the field strength is about 625.0V / cm), heat and hold the pressure After 10 minutes, the voltage rises to 300V (the field strength is about 750.0V / cm), after 10 minutes of heat preservation and pressure holding, the voltage rises to 320V (the field strength is about 800.0V / cm), the current value is controlled to 1A, and the sample is turned off after 180s The voltage at both ends and the power supply of the muffle furnace allow the sampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com