A kind of preparation method and application of europium-doped calcium molybdate powder

A technology of europium calcium molybdate and powder, which is applied in the field of luminescent material preparation, can solve the problems of cumbersome dichromate detection method and poor dichromate sensitivity, and achieve the effects of easy implementation, simple operation and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) CaMoO 4 :Eu 3+ Powder preparation

[0030] (1) Mix 15mL of absolute ethanol, 0.4676g Ca(NO 3 ) 2 , 67uL 0.2mol / L Eu(NO 3 ) 3 Pour the aqueous solution into a mortar, add 2g of gum arabic powder, and then grind for 5min;

[0031] (2) Add 0.353g (NH 4 ) 6 MoO 24 , grind for 30min;

[0032] (3) Put the above-mentioned mortar into an oven, bake at 100°C for 4 hours, put it in a muffle furnace after drying, and roast at 600°C for 3 hours, and then get CaMoO after cooling 4 :Eu 3+ Powder.

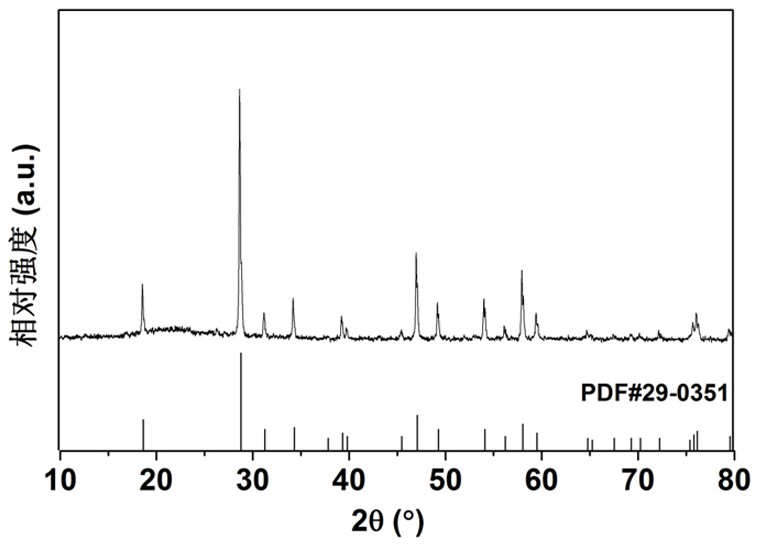

[0033] The obtained product was analyzed by X-ray diffraction as figure 1 shown by figure 1 It can be seen that according to JCPDS29-0351, the obtained calcium molybdate has a scheelite structure.

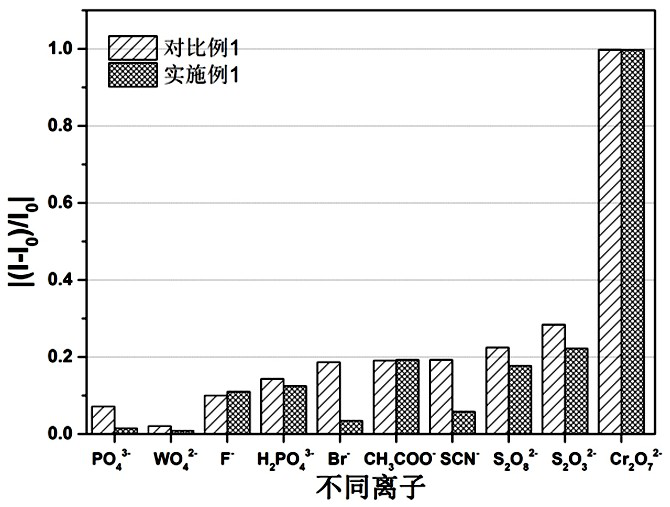

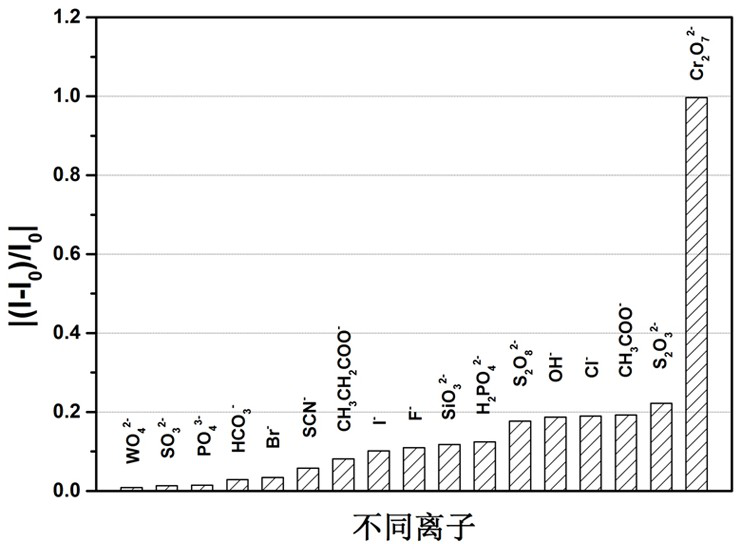

[0034] (2) Detection of different anions

[0035] 0.0070g CaMoO 4 :Eu 3+ The powder was dissolved in 50ml water to prepare CaMoO 4 :Eu 3+ solution, prepare several groups of centrifuge tubes, pipette 1500 μL CaMoO 4 :Eu 3+ solution in individual centrifuge tubes. Prepa...

Embodiment 2

[0062] (1) CaMoO 4 :Eu 3+ Powder preparation

[0063] (1) Mix 15mL of absolute ethanol, 0.4676g Ca(NO 3 ) 2 , 67uL 0.2mol / L Eu(NO 3 ) 3 Pour the aqueous solution into a mortar, add 2g of gum arabic powder, and then grind for 5min;

[0064] (2) Add 0.353g (NH 4 ) 6 MoO 24 , grind for 30min;

[0065] (3) Put the above-mentioned mortar into an oven, bake at 100°C for 4 hours, put it in a muffle furnace after drying, and roast at 600°C for 3 hours, and then get CaMoO after cooling 4 :Eu 3+ Powder.

[0066] The obtained product was analyzed by X-ray diffraction as figure 1 shown by figure 1 It can be seen that according to JCPDS29-0351, the obtained calcium molybdate has a scheelite structure.

[0067] (2) Drawing of standard curve

[0068] (1) Add 0.0070g CaMoO 4 :Eu 3+ The powder is dissolved in 50ml of water, and a series of concentration gradients of potassium dichromate and the above-mentioned CaMoO 4 :Eu 3+ Standard solution mixed with solution, the final c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com