Lithium-sulfur battery diaphragm and preparation method thereof

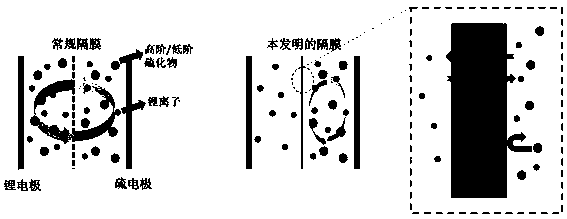

A lithium-sulfur battery and separator technology, applied in the field of lithium battery and its preparation, can solve problems such as uneven surface of lithium metal negative electrode, reduction of coulombic efficiency of lithium-sulfur battery, loss of sulfur-containing components of the battery, etc., to inhibit the growth of lithium dendrites , Improve cycle efficiency, improve cycle stability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

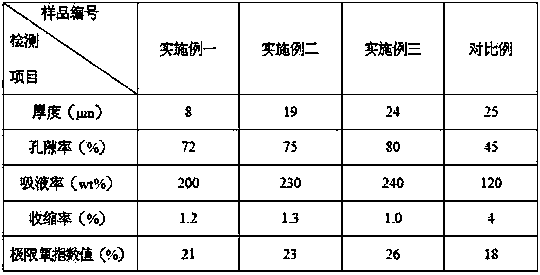

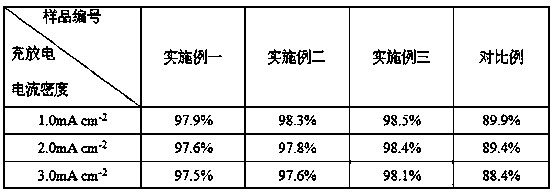

Examples

Embodiment 1

[0021] Step 1: Soak 20g of K-type carrageenan powder in 50g of NaOH solution with a concentration of 3mol / L, and magnetically stir (250rpm) in a water bath at 50°C for 30 minutes to obtain a clear and transparent solution. Centrifuge at 3500 rpm for 5 minutes, take the supernatant and add absolute ethanol to adjust the concentration to 10%, to prepare an electrospinning solution.

[0022] Step 2: Put the electrospinning solution obtained in step 1 into the spinneret, wind the 5 μm polyethylene diaphragm on the receiving drum, the speed of the receiving drum is 400rpm, and the distance from the spinneret to the receiver drum is 12cm. The power output was 15kV static voltage, the temperature was 30°C, the humidity was 20% and the spinning speed was 0.002mm / s, and the polyethylene separator coated with carrageenan gel coating on one side was prepared.

[0023] Step 3: the polyethylene diaphragm that the single side that step 2 obtains is coated with carrageenan gel coating is wou...

Embodiment 2

[0025] Step 1: Soak 30g of L-type carrageenan powder in 200g of NaOH solution with a concentration of 5mol / L, and magnetically stir (280rpm) in a water bath at 60°C for 40 minutes to obtain a clear and transparent solution. Centrifuge at 3500 rpm for 5 minutes, take the supernatant and add absolute ethanol to adjust the concentration to 11%, to prepare an electrospinning solution.

[0026] Step 2: Put the electrospinning solution obtained in step 1 into the spinneret, wind the 15 μm polyvinylidene fluoride diaphragm on the receiving drum, the speed of the receiving drum is 500 rpm, and the distance from the spinneret to the receiver drum is 15 cm. The high-voltage DC power supply output 18kV static voltage, the temperature is 35 ℃, the humidity is 22% of the environment, the spinning speed is 0.003mm / s, and the polyvinylidene fluoride diaphragm coated with carrageenan gel coating on one side is prepared. .

[0027] Step 3: Wind the polyvinylidene fluoride diaphragm coated wit...

Embodiment 3

[0029] Step 1: Soak 20g of K-type carrageenan powder and 20g of I-type carrageenan powder in 300g of NaOH solution with a concentration of 6mol / L, and stir magnetically (320rpm) in a water bath at 70°C for 50 minutes to obtain clarification transparent solution, centrifuge the obtained solution at 3500 rpm for 5 minutes, take the supernatant and add absolute ethanol to adjust the concentration to 12%, to prepare an electrospinning solution.

[0030] Step 2: Put the electrospinning solution obtained in step 1 into the spinneret, wind the 20 μm non-woven fabric diaphragm on the receiving drum, the speed of the receiving drum is 600 rpm, and the distance from the spinneret to the receiver drum is 18 cm. The output of the DC power supply is 20kV static voltage, the temperature is 40°C, the humidity is 25% and the spinning speed is 0.005mm / s, and the non-woven separator coated with carrageenan gel coating on one side is prepared.

[0031] Step 3: Wind the non-woven membrane of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com