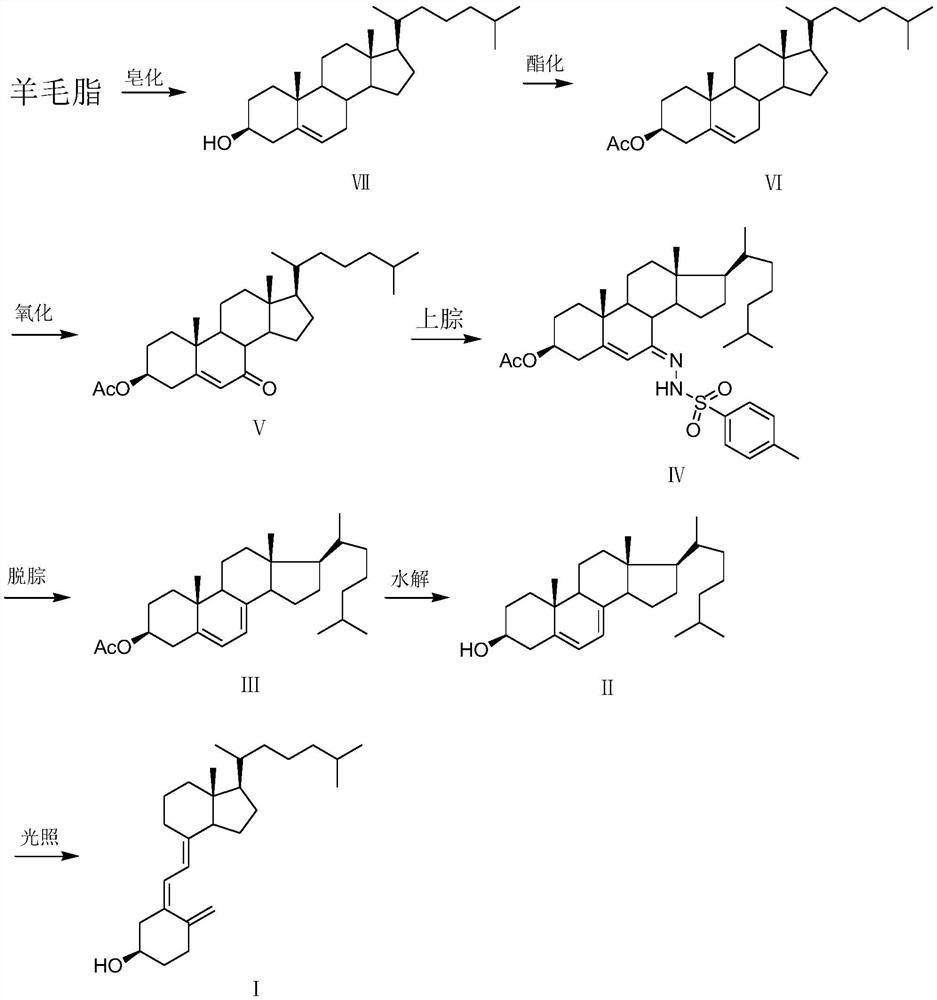

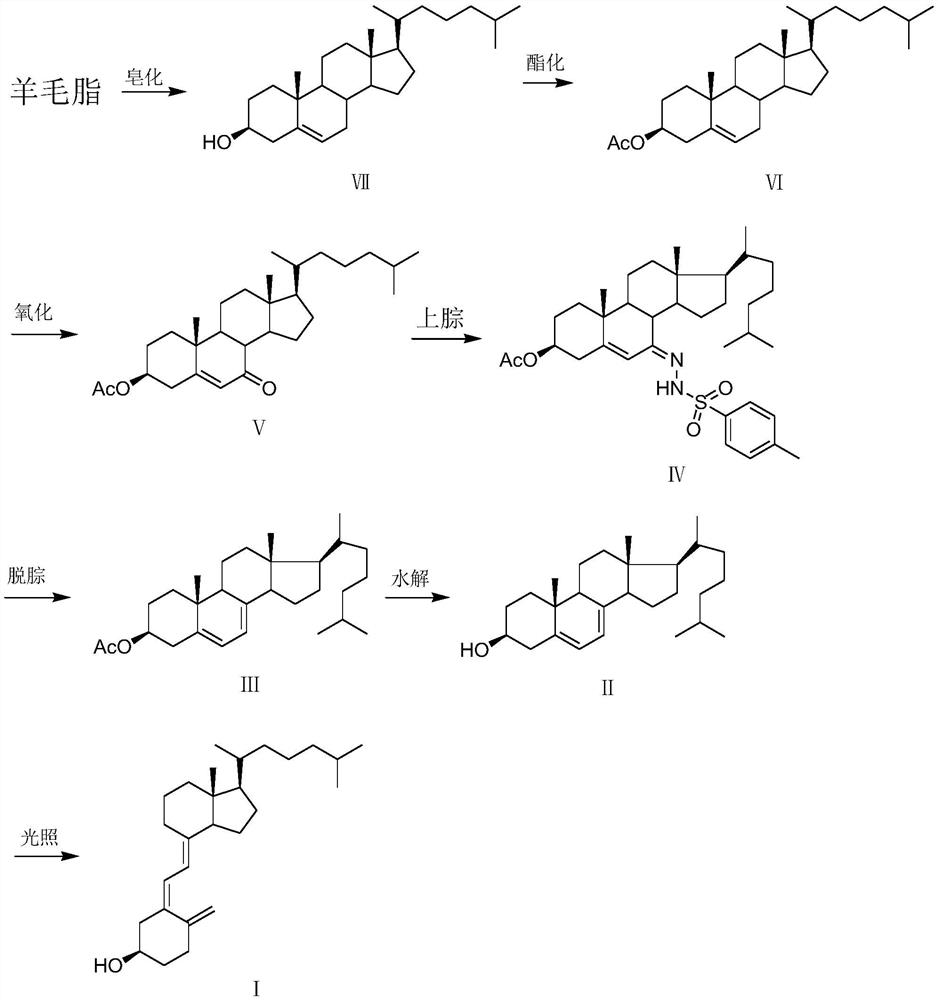

A kind of production of vitamin D with lanolin as raw material 3 new method of industrialization

A vitamin and saponification technology, applied in the direction of organic chemistry, can solve the problems of no industrialization, uneconomical economic cost, low yield and purity, etc., and achieve the effects of reducing reagent consumption, strong industrial operability, and simplified process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1 lanolin saponification

[0030] Add 50 kg of lanolin into the reaction kettle, then add 500 L (about 420 kg) of 80% methanol and 10 kg of sodium hydroxide, and saponify under reflux for 8 hours. Cool naturally after saponification, and filter; the filtrate supplements the consumed sodium hydroxide 3kg and uses it mechanically as the next saponification solution.

[0031] Or: Concentrate the above-mentioned filtrate under reduced pressure to about 50L to precipitate a large amount of sodium lanolate, remove the sodium lanolate by filtration, add 3Kg of sodium hydroxide to the filtrate, and use it as the next saponification solution.

Embodiment 2

[0032] Embodiment 2 Crystallization removes lanolin

[0033] Dry the filter cake obtained in Example 1 to obtain 15 kg, dissolve it with 75-150 kg of petroleum acetone (volume ratio 1:1), cool and crystallize to produce lanolin alcohol, filter, and concentrate the filtrate to dryness under reduced pressure to enter the next step for processing , and the filter cake was dried to obtain 4Kg of lanolin alcohol.

Embodiment 3

[0034] Example 3 Crystallization to remove lanosterol to obtain crude cholesterol

[0035] Add 50 times of weight methanol to the filtrate concentrate in Example 2 to separate out lanosterol, filter and dry to obtain about 4Kg of lanosterol solid; Lanosterol is monitored and detected by thin-layer chromatography until the filtrate only has a single spot of cholesterol and is concentrated to dryness to obtain 7 kg of crude cholesterol.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com