A kind of sanitary napkin preparation process

A preparation process and technology of sanitary napkins, which are applied in the field of sanitary products, can solve the problems of uneven female care effects, unguaranteed comfort, single function of sanitary napkins, etc., to inhibit the growth and reproduction of bacteria, promote rapid transmission, and improve sterilization and antibacterial The effect of bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

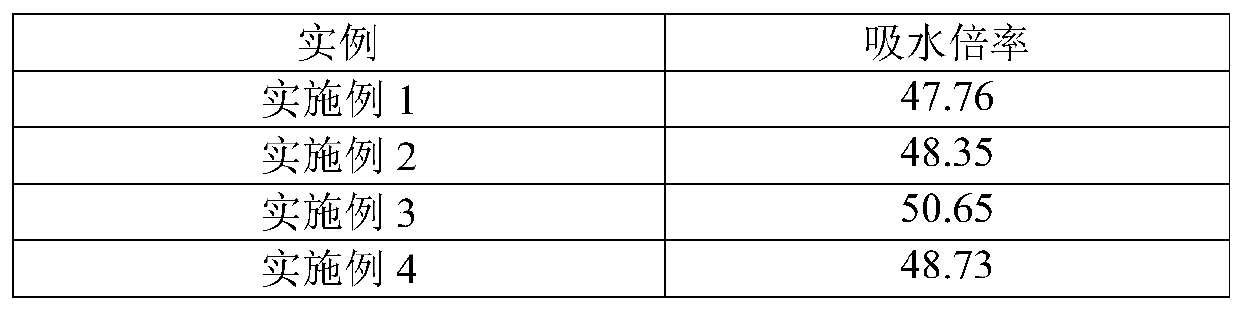

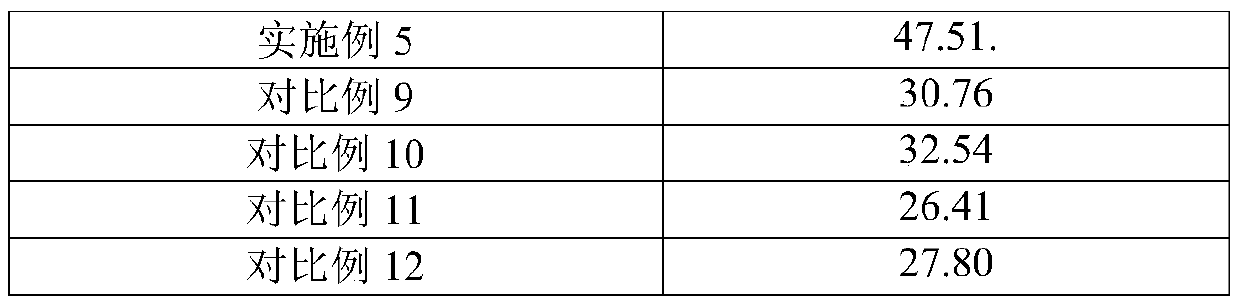

Examples

Embodiment 1

[0040] A kind of sanitary napkin preparation process, comprises the following steps:

[0041] (1) Dissolve 5 parts by weight of starch in 60 parts by weight of water, adjust the temperature of the water bath to 60°C and add 10 parts by weight of sodium hydroxide, 25 parts by weight of acrylic acid, 20 parts by weight of potassium persulfate, and 3 parts by weight of pentaerythritol Triallyl ether and 6 parts by weight of methylene succinic acid were stirred at 150 r / min for 20 minutes and then dried to obtain a superabsorbent material; the cotton fiber and bamboo fiber with a weight ratio of 1:1 were sheared and mixed and then melted and extruded After the composite fiber is cooled, it is formed into a web, bonded and strengthened, trimmed and wound, and then filled with superabsorbent material. The filling amount of superabsorbent material is 3000g / m 2 , to obtain a water-absorbing layer;

[0042] (2), heat 300 parts by weight of polyethylene at 100°C to melt, add 10 parts b...

Embodiment 2

[0048] A kind of sanitary napkin preparation process, comprises the following steps:

[0049] (1) Dissolve 10 parts by weight of starch in 80 parts by weight of water, adjust the temperature of the water bath to 60°C and add 20 parts by weight of sodium hydroxide, 35 parts by weight of acrylic acid, 40 parts by weight of potassium persulfate, 6 parts by weight of N , N-methylenebisacrylamide and 10 parts by weight of L-ascorbic acid, stirred at 150r / min for 20min and then dried to obtain a superabsorbent material; the cotton fiber and bamboo fiber with a weight ratio of 1:3 were cut and mixed and then melted Extruded to form composite fibers, after the composite fibers are cooled, formed into a net, bonded and reinforced, trimmed and wound, filled with super-absorbent material, the filling amount of super-absorbent material is 3000g / m 2 , to obtain a water-absorbing layer;

[0050] (2) Heat 500 parts by weight of polyethylene at 100°C to melt, add 20 parts by weight of polyvi...

Embodiment 3

[0056] A kind of sanitary napkin preparation process, comprises the following steps:

[0057] (1) Dissolve 8 parts by weight of starch in 70 parts by weight of water, adjust the temperature of the water bath to 60°C and add 16 parts by weight of sodium hydroxide, 30 parts by weight of acrylic acid, 32 parts by weight of potassium persulfate, 4.5 parts by weight of N -(3-Dimethylaminopropyl) methacrylamide and 8 parts by weight of citric acid, stirred at 150r / min for 20min and then dried to obtain a superabsorbent material; the cotton fiber and bamboo fiber with a weight ratio of 1:2 were sheared After mixing, melt and extrude to form composite fibers. After the composite fibers are cooled, they are formed into a net, bonded and reinforced, trimmed and wound, and then filled with super-absorbent materials. The filling amount of super-absorbent materials is 5000g / m 2 , to obtain a water-absorbing layer;

[0058] (2) Heat 400 parts by weight of polyethylene to melting at 100°C, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com