Catalyst for catalytic combustion of ketone-containing benzene tail gas and preparation method thereof

A technology of combustion catalyst and catalytic combustion, which is applied in the direction of catalyst activation/preparation, combustion method, physical/chemical process catalyst, etc., to achieve the effects of improving wear resistance, avoiding weak adhesion, and improving activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

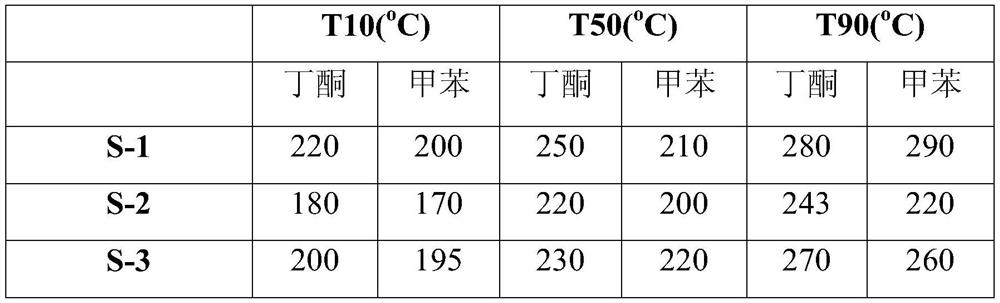

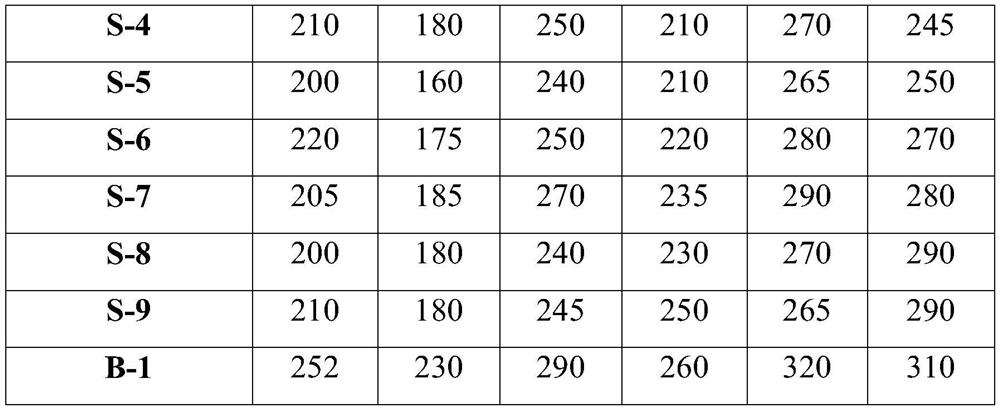

Embodiment 1

[0028] Weigh CeO prepared by homogeneous method 2 1g, to be thin 10g, aluminum nitrate nonahydrate 6.5g, γ-Al 2 o 3 1.3g, aluminum hydroxide Al(OH) 3 6.5g, 30g of water, put into a ball mill and mill for 4 hours to prepare slurry A; soak 1ml of 400-mesh honeycomb ceramic carrier in the slurry for 5min, take it out, blow out the excess slurry in the pores with compressed air, and then microwave dry , baked at 600°C for 2 hours to obtain a carrier B coated with a mixed oxide coating; dip the carrier B coated with a mixed oxide coating into a palladium nitrate solution, blow out the excess solution in the pores of the honeycomb carrier with compressed air; After drying for 5 minutes, it was calcined at 550° C. for 4 hours to obtain monolithic catalyst C. The prepared catalyst was prepared in 10vol.%H 2 -90vol.%N 2 Under atmosphere, 450 DEG C reduced for 2 hours, obtained the monolithic structure catalyst S-1 (0.1wt%Pd / 20wt.%(0.94Al 2 o 3 -0.06CeO 2 ) / cordierite honey...

Embodiment 2

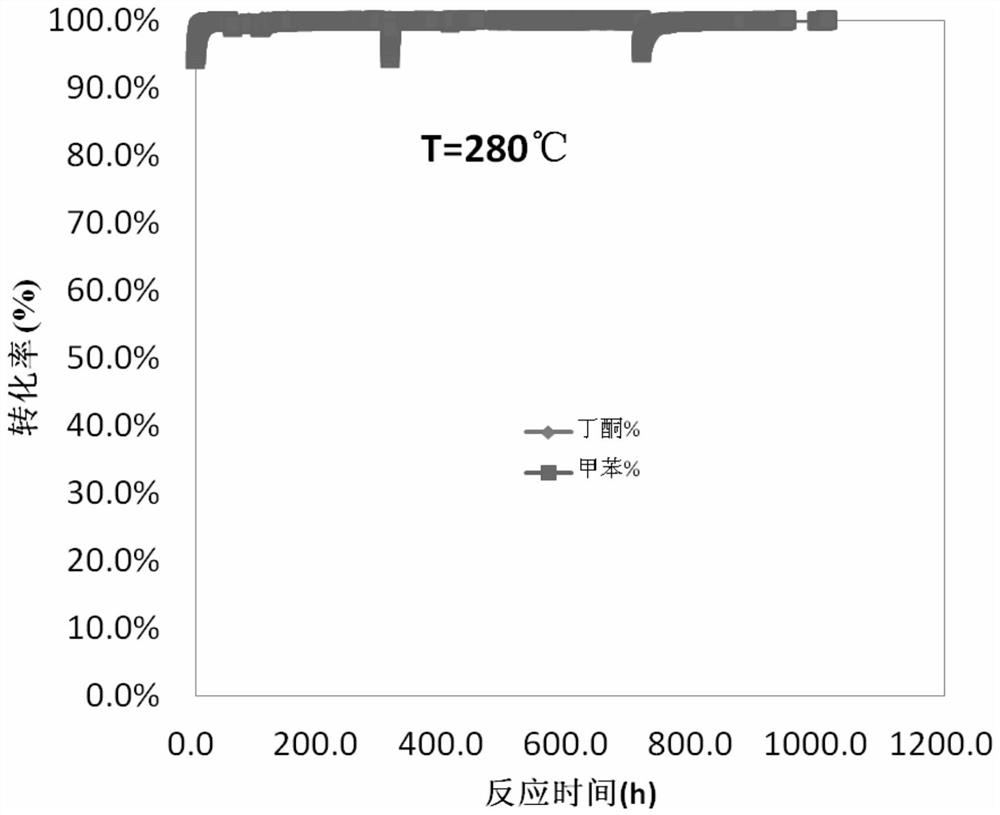

[0030] Weigh 8.0g of ammonium cerium nitrate, 10g of pseudothin, 6.5g of aluminum nitrate, γ-Al 2 o 3 1.3g, aluminum hydroxide Al(OH) 3 6.5g, 30g of water, put into a ball mill jar and mill for 2 hours to prepare slurry A; soak 1ml of 400 mesh honeycomb ceramic carrier in the slurry for 5min and take it out, blow out the excess slurry in the pores with compressed air, and then microwave dry , baked at 600°C for 2 hours to obtain a carrier B coated with a mixed oxide coating; dip the carrier B coated with a mixed oxide coating into a platinum nitrate solution, blow out the excess solution in the pores of the honeycomb carrier with compressed air; After drying for 5 minutes, it was calcined at 550° C. for 4 hours to obtain monolithic catalyst C. The prepared catalyst was heated at 10vol.%H 2 -90vol.%N 2 Under the atmosphere, 450 ℃ reduced for 2 hours, and the monolithic catalyst S-2 (0.2wt%Pt / 30wt.%(0.86Al 2 o 3 -0.14CeO 2 ) / cordierite honeycomb). Catalyst S-2 continuou...

Embodiment 3

[0032] Weigh 2.5g of manganese nitrate, 5g of pseudothin, 4g of aluminum nitrate, γ-Al 2 o 3 8.2g, aluminum hydroxide Al(OH) 3 3g, 30g of dilute nitric acid, added into a ball mill and milled for 4 hours to prepare slurry A; soak 1ml of 400 mesh honeycomb ceramic carrier in the slurry for 5min and take it out, blow out the excess slurry in the pores with compressed air, and then microwave dry , baked at 600°C for 2 hours to obtain a carrier B coated with a mixed oxide coating; dip the carrier B coated with a mixed oxide coating into a palladium nitrate solution, and blow out the excess solution in the pores of the honeycomb carrier with compressed air; microwave After drying for 5 minutes, it was calcined at 550° C. for 4 hours to obtain monolithic catalyst C. The prepared catalyst was heated at 10vol.%H 2 -90vol.%N 2 Under atmosphere, 450 ℃ of reductions 2 hours, make the whole structure catalyst S-3 (0.1wt%Pd / 23wt.%(0.94Al 2 o 3 -0.06MnO 2 ) / cordierite honeycomb).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com