Biomass composite for toothbrush handle and preparation method of biomass composite

A composite material and biomass technology, applied in the field of biodegradable polymer materials, can solve the problem of poor toughness, strength, plasticity and physical and mechanical properties of composite materials, product toughness, plasticity and physical and mechanical properties, and affect the complete degradability of blends and other problems, to achieve excellent mechanical properties, good biodegradability, improve the effect of dispersion and interfacial bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

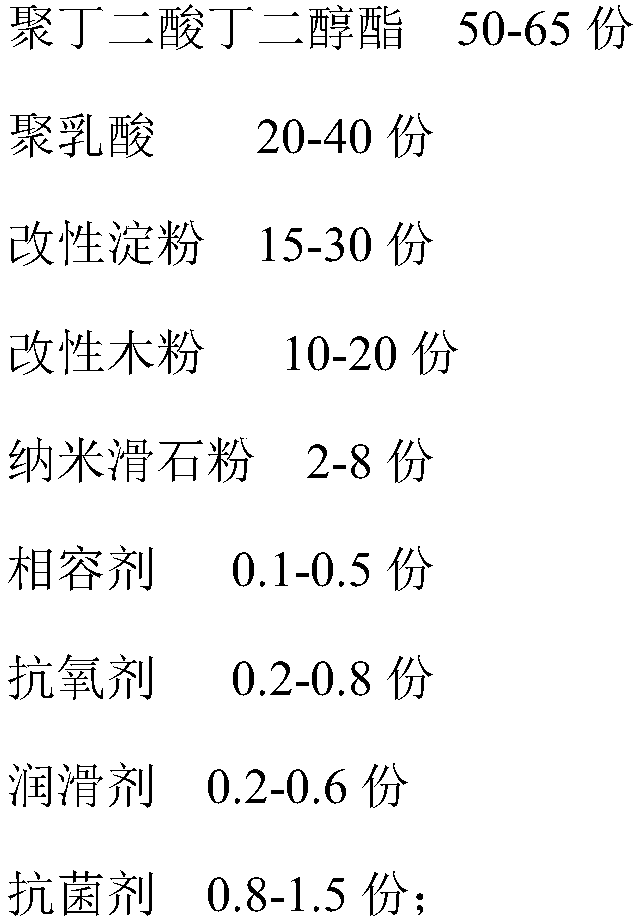

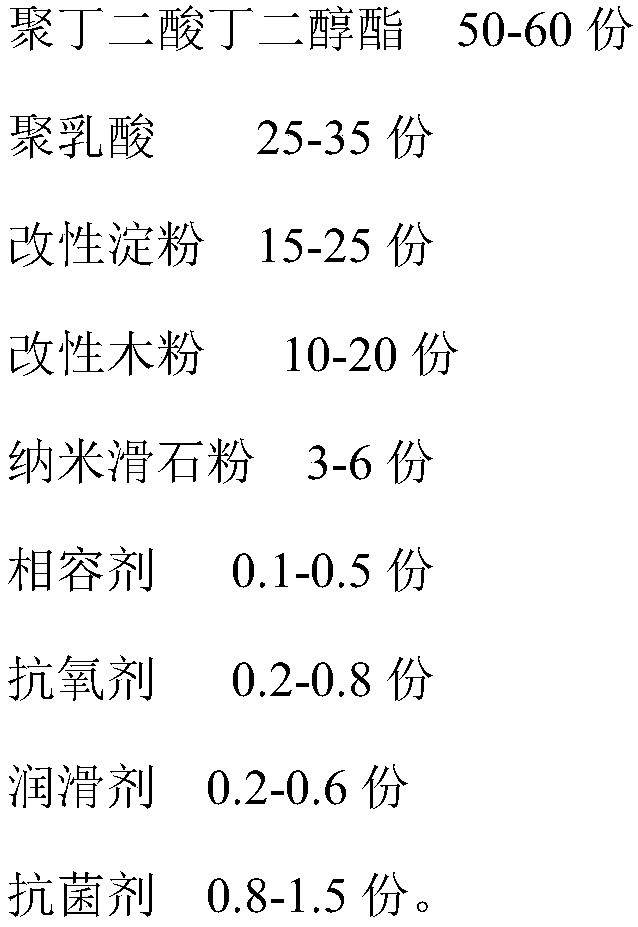

[0039] A kind of biomass composite material that is used for toothbrush handle of the present embodiment, preparation method is as follows (the following components are all in parts by weight):

[0040] Step a, prepare modified wood flour:

[0041] a1) Weigh 45 parts of L-lactide and 50 parts of log powder and dry at 60°C for 3.5 hours to control the moisture content to ≤0.02%; weigh 2 parts of stannous octoate and use toluene as a solvent to prepare the mass of stannous octoate Concentration is 2% toluene solution, standby;

[0042] a2) Add L-lactide into the reactor, and gradually raise the temperature to 110°C under stirring. After the L-lactide is completely melted, add the dried log powder and keep the constant temperature to make the L-lactide and log powder Mix well and evenly;

[0043] In the above steps, the log powder is a mixture of teak powder, birch powder and poplar powder in a mass ratio of 1:1:1, and the particle size is 60 mesh.

[0044] a3) Warm up to 130°...

Embodiment 2

[0053] A kind of biomass composite material that is used for toothbrush handle of the present embodiment, preparation method is as follows (the following components are all in parts by weight):

[0054] Step a, prepare modified wood flour:

[0055] a1) Weigh 40 parts of L-lactide and 55 parts of log powder and dry at 65°C for 3 hours to control the moisture content to ≤0.02%; weigh 1 part of dibutyltin dilaurate and use toluene as a solvent to prepare dilauric acid Dibutyltin mass concentration is 2-6% toluene solution, standby;

[0056] a2) Add L-lactide into the reactor, and gradually raise the temperature to 115°C under stirring. After the L-lactide is completely melted, add the dried log powder and keep a constant temperature to make L-lactide and log powder Mix well and evenly;

[0057] In the above steps, the log powder is a mixture of poplar wood powder and pine wood powder in a mass ratio of 2:1, and its particle size is 70 orders;

[0058] a3) Warm up to 130°C, add...

Embodiment 3

[0067] A kind of biomass composite material that is used for toothbrush handle of the present embodiment, preparation method is as follows (the following components are all in parts by weight):

[0068] Step a, prepare modified wood flour:

[0069] a1) Weigh 55 parts of L-lactide and 45 parts of log powder and dry at 55°C for 4 hours to control the moisture content to ≤0.02%; weigh 3 parts of stannous octoate and use toluene as a solvent to prepare the mass concentration of stannous octoate 6% toluene solution, standby;

[0070] a2) Add L-lactide into the reactor, and gradually raise the temperature to 120°C under stirring. After the L-lactide is completely melted, add the dried log powder and keep a constant temperature to make the L-lactide and log powder Mix well and evenly;

[0071] In the above steps, the log powder is a mixture of teak powder, birch powder and poplar powder in a mass ratio of 3:5:1, and its particle size is 80 orders;

[0072] a3) Warm up to 130°C, ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com