Aluminate red phosphor activated by europium ions Eu3+ and preparation method of aluminate red phosphor

A technology of red fluorescent powder and europium ions, which is applied in the direction of chemical instruments and methods, luminescent materials, etc., can solve the problems of weakening the brightness of luminescence, and the application is not optimistic, and achieves good chromaticity, simple and easy preparation method, and uniform distribution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

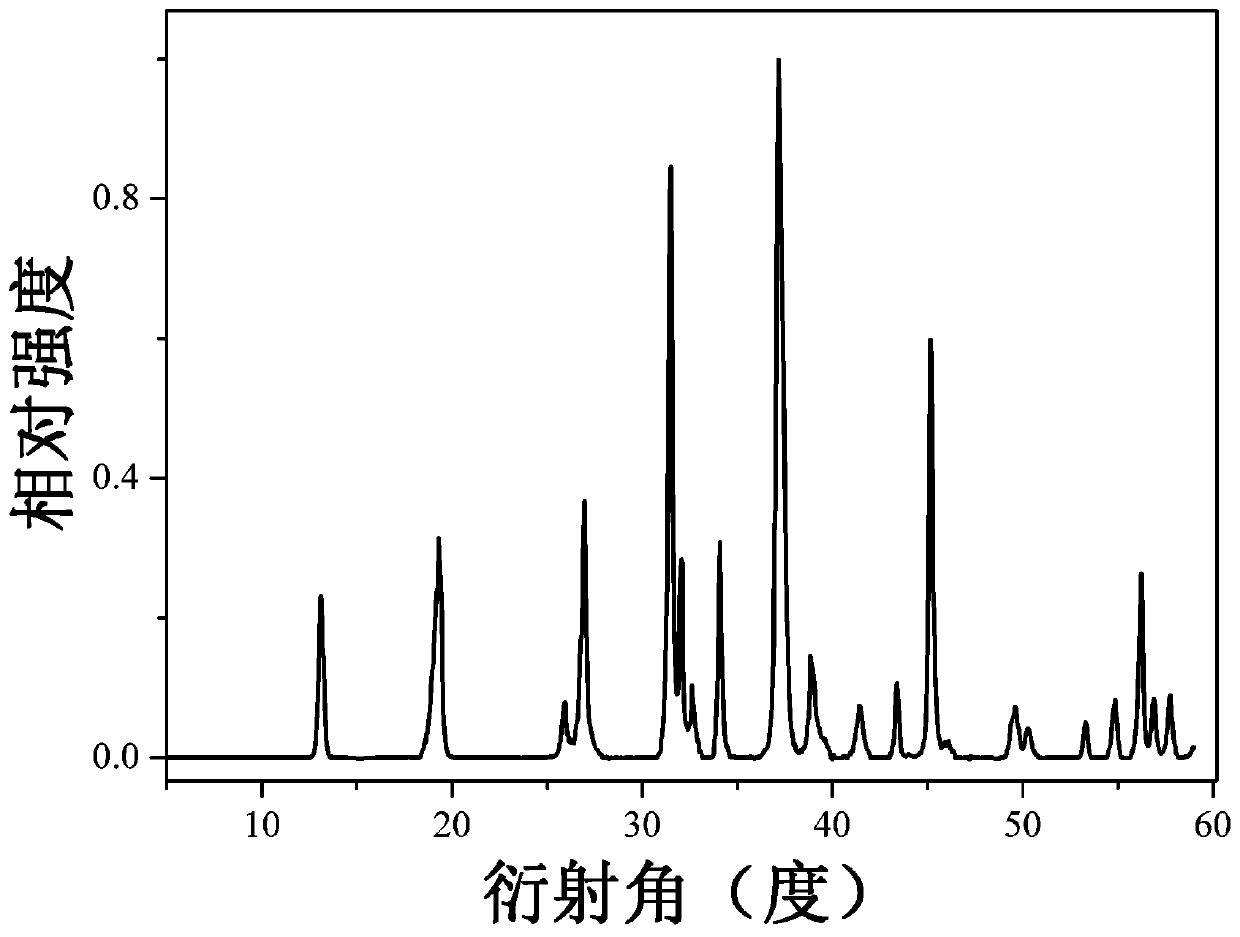

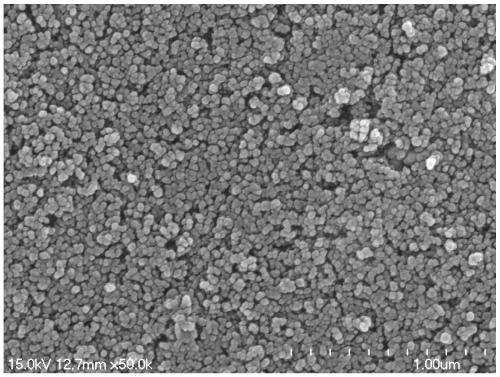

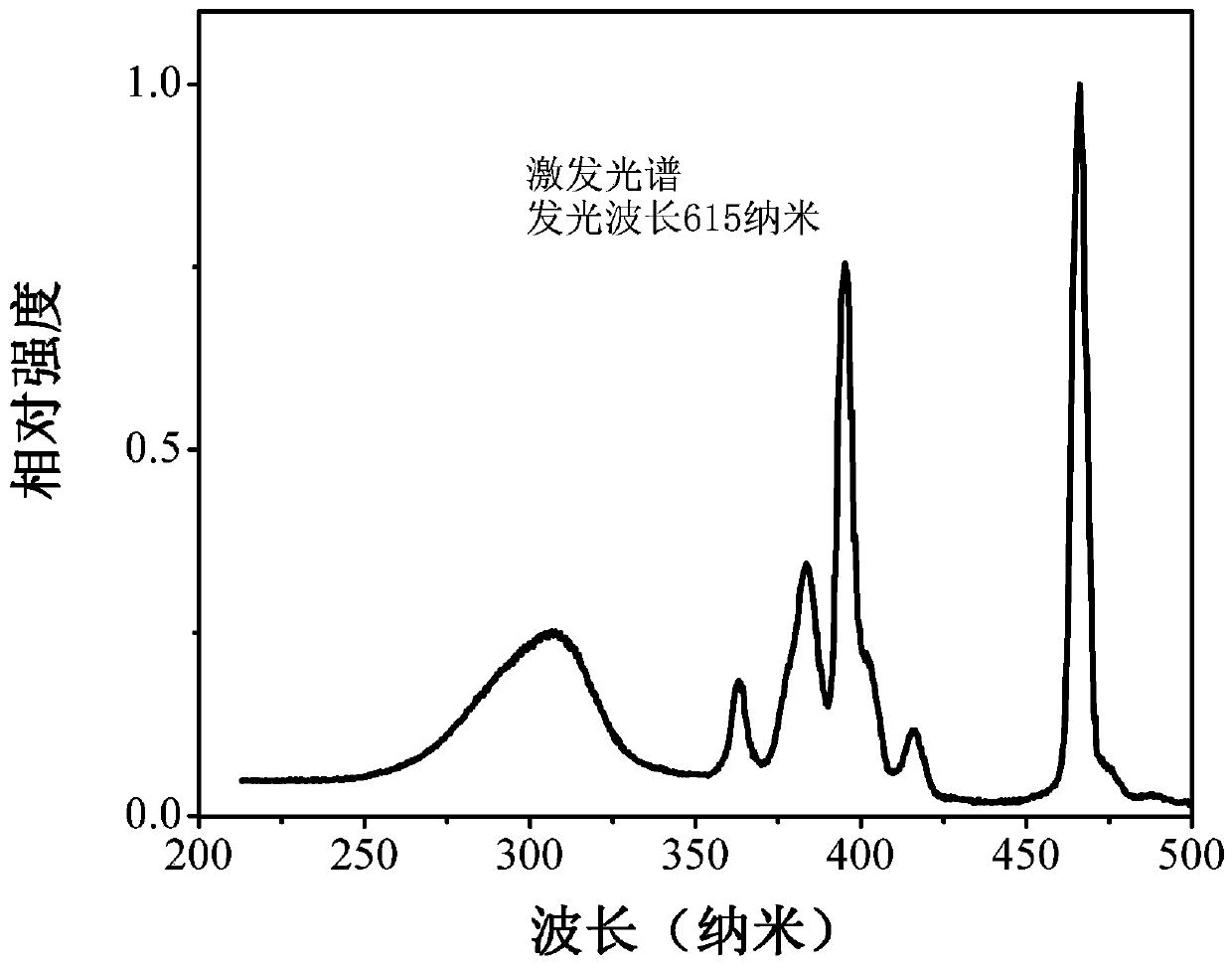

Embodiment 1

[0030] Preparation of Zn 2.79 Eu 0.21 MgAl 22 o 37 : According to the chemical formula Zn 2.79 Eu 0.21 MgAl 22 o 37 The stoichiometric ratio of each element in the raw material is weighed respectively: zinc nitrate Zn(NO 3 ) 2 ·6H 2 O: 1.494g, europium nitrate Eu(NO 3 ) 3 ·6H 2 O: 0.149g, magnesium basic carbonate 4MgCO 3 ·Mg(OH) 2 ·5H 2 O: 0.1748g, aluminum nitrate Al(NO 3 ) 3 9H 2 O: 14.85g, each raw material weighed above was dissolved in nitric acid and diluted with deionized water, 0.91g oxalic acid was added to the zinc nitrate solution, 0.1g oxalic acid was added to the basic magnesium carbonate solution, and 0.1g oxalic acid was added to the europium nitrate solution Add 0.07g of oxalic acid, add 7.13g of oxalic acid to the aluminum nitrate solution, stir for a period of time until the oxalic acid dissolves to obtain each raw material solution; mix the above raw material solutions, and stir at 85°C, and dry to obtain the precursor sol ; The precursor ...

Embodiment 2

[0037] Preparation of Zn 2.7 Eu 0.3 MgAl 22 o 37 : According to the chemical formula Zn 2.7 Eu 0.3 MgAl 22 o 37 The stoichiometric ratio of each element in the formula is weighed respectively Raw materials: zinc oxide ZnO: 0.88g, europium oxide Eu 2 o 3 : 0.212g, magnesium nitrate Mg(NO 3 ) 2 : 0.6g, aluminum oxide Al 2 o 3 : 4.48g, each raw material weighed above is dissolved in nitric acid respectively and diluted with deionized water, 2.07g of citric acid is added in the zinc oxide solution, citric acid is added in the magnesium nitrate solution: 0.77g, in the europium oxide solution Add citric acid: 0.115g, add citric acid: 4.45g to the alumina solution, stir for a period of time until the citric acid dissolves to obtain each raw material solution; mix the above raw material solutions, stir at 50°C, and dry Finally, the precursor sol was obtained; the precursor sol was calcined at 350°C for 10h to obtain a precursor mixture, and then the precursor mixture was g...

Embodiment 3

[0040] Preparation of Zn 2.997 Eu 0.003 MgAl 22 o 37 : According to the chemical formula Zn 2.997 Eu 0.003 MgAl 22 o 37 The stoichiometric ratio of each element is weighed respectively Raw materials: zinc hydroxide Zn(OH) 2 : 2.68g, europium nitrate Eu(NO 3 ) 3 ·6H 2 O: 0.0129g, magnesium oxide MgO: 0.36g, aluminum hydroxide Al(OH) 3 : 15.44g, each raw material weighed above was dissolved in nitric acid and diluted with deionized water, 2.67g oxalic acid was added to the zinc hydroxide solution, oxalic acid was added to the magnesium oxide solution: 0.891g was added to the europium nitrate solution Oxalic acid: 0.01g, add oxalic acid: 19.6g to the aluminum hydroxide solution, stir for a period of time until the oxalic acid is dissolved to obtain each raw material solution; mix the above raw material solutions, stir at 80°C, and dry to obtain the precursor body sol; the precursor sol was calcined at 650°C for 7h to obtain a precursor mixture, and then the precursor m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com