A temperature-resistant and salt-resistant multi-component copolymer and its preparation method and application

A multi-component copolymer and water-soluble polymer technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of terminal halogen loss, decreased control effect, and less research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

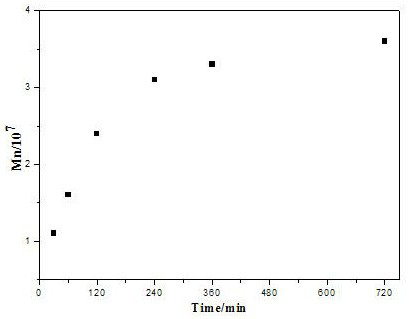

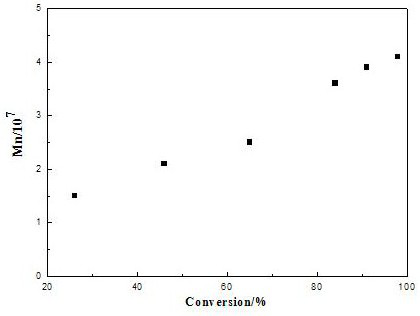

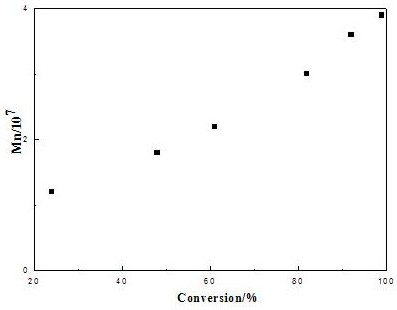

Image

Examples

Embodiment 1

[0052] Embodiment 1: the preparation of temperature-resistant polyfunctionality macromolecular initiator

[0053] PVP is a temperature-resistant water-soluble multi-component copolymer, and FO (fluorenone) is a photoinitiator to prepare a temperature-resistant multifunctional macromolecular initiator containing dormant groups in the side chain. The steps are as follows:

[0054] In a 200mL quartz photoreactor, add 5.0g PVP K30 (polyvinylpyrrolidone-K30) dissolved in 50mL water to prepare 10wt% PVP aqueous solution, 1.25g FO dissolved in 50mL ethanol to prepare 2.5wt% FO ethanol solution, the system was mixed uniformly, and then 3.5g of monomer AM (acrylamide) and 1.5g of AMPS (2-acrylamido-2-methylpropanesulfonic acid) were added to the solution; the reaction system was closed after 10 minutes of deoxygenation with nitrogen gas , the reaction system was irradiated under a UV light source, and the light intensity was set to 4000μW / cm 2 ; The irradiation time was set to 30 minu...

Embodiment 2

[0055] Embodiment 2: the preparation of temperature-resistant polyfunctionality macromolecular initiator

[0056] PVP is a temperature-resistant water-soluble multi-polymer, FO is a photoinitiator, and the temperature-resistant multifunctional macromolecular initiator containing dormant groups in the side chain is prepared. The steps are as follows:

[0057] In a 200mL quartz photoreactor, add 10wt% PVP aqueous solution prepared by dissolving 5.0g PVP K30 in 50mL water, and 5wt% FO ethanol solution prepared by dissolving 1.0g FO in 25mL ethanol. Add 4.0g of monomer AM and 1.0g of AMPS; after 10 minutes of deoxygenation with nitrogen gas, the reaction system is closed, and the reaction system is irradiated under an ultraviolet light source, and the light intensity is set to 2000μW / cm 2 ; The irradiation time was set to 30 minutes. After the reaction, the polymer mixed solution was precipitated with 100mL cold ethanol, and the temperature-resistant multifunctional macromolecula...

Embodiment 3

[0058] Embodiment 3: the preparation of temperature-resistant polyfunctionality macromolecular initiator

[0059] PVP is a temperature-resistant water-soluble multi-polymer, FO is a photoinitiator, and the temperature-resistant multifunctional macromolecular initiator containing dormant groups in the side chain is prepared. The steps are as follows:

[0060] In a 200mL quartz photoreactor, add 10wt% PVP aqueous solution prepared by dissolving 5.0g PVP K30 in 50mL water, and 5wt% FO ethanol solution prepared by dissolving 1.25g FO in 25mL ethanol. Add 8.0g of monomer AM and 2.0g of AMPS; after 10 minutes of deoxygenation with nitrogen gas, the reaction system is sealed, and the reaction system is irradiated under an ultraviolet light source, and the light intensity is set to 5000μW / cm 2 ; The irradiation time was set to 30 minutes. After the reaction, the polymer mixed solution was precipitated with 100mL cold ethanol, and the temperature-resistant multifunctional macromolecul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com