Power generation building material and preparation method thereof

A technology for building materials and photovoltaic power generation, applied in photovoltaic power generation, circuits, electrical components, etc., it can solve the problems that photovoltaic modules cannot be used in large quantities, flash, dizziness, and single color of components, etc., to achieve colorful appearance, low curing temperature, wide The effect of the application foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

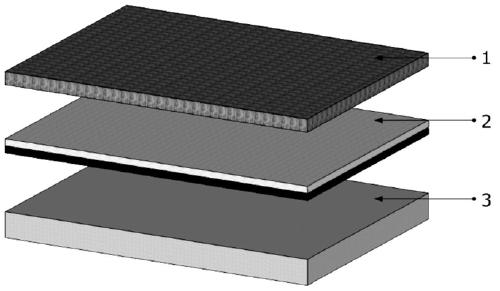

[0069] A building material for power generation. The base layer of the building material is flexible stainless steel foil with a thickness of 0.2 mm. A photoelectric conversion layer is arranged on it, and electrodes are led out through wires. A building material finish protective layer is arranged on the photoelectric conversion layer.

[0070] The preparation method of the photoelectric conversion layer is as follows:

[0071] Clean the flexible stainless steel foil substrate and put it into the magnetron sputtering machine. In order to prevent elements in the stainless steel from diffusing into the solar cell, a WTi barrier layer with a thickness of 0.5 μm was sputtered first. The working gas is Ar gas, the sputtering pressure is 0.7Pa, and the background vacuum is 2.0×10 -3 Pa, the substrate is not heated during sputtering. The Mo film was prepared by the three-layer process, the sputtering pressure of the first layer was 1.5Pa, the sputtering pressure of the second lay...

Embodiment 2

[0076] A power generation building material, the base of which is glass with a thickness of 2.0 mm, a photoelectric conversion layer is arranged on it, and a wire lead-out electrode is provided. The preparation process of the photoelectric conversion layer is similar to that of Example 1, except that the CIGS film is replaced by the copper zinc tin sulfur selenium film, and the post-treatment process of the CZTSSe film is replaced by selenization and sulfurization. A barrier layer is arranged on the battery layer, the barrier layer is EVA and glass, and the building material finish protection layer is prepared by manual spraying.

[0077] The ratio of raw materials for the building material facing protective layer: in parts by weight, the mother liquor accounts for 186 parts, and the pigment accounts for 5 parts. The mother liquor used includes 45 parts of potassium silicate and 130 parts of filler, which is a mixture of talcum powder, calcium carbonate and kaolin in a weight ...

Embodiment 3

[0080] A building material for power generation, the base of which is ceramic tiles with a thickness of 8.0 mm, a photoelectric conversion layer is arranged on it, and lead-out electrodes are arranged. The photoelectric conversion layer is a CdTe solar cell, and a barrier layer is arranged on the cell layer. The barrier layer is PVB and ETFE, and a building material facing protective layer is prepared on the barrier layer, and its thickness is 5mm.

[0081] Raw material ratio of building material facing protective layer: by weight, the mother liquor accounts for 100 parts, and the pigment accounts for 5 parts. The mother liquor raw material includes base material, filler and auxiliary agent; the base material accounts for 60 parts, the filler accounts for 18 parts, and the auxiliary agent accounts for 3.8 parts. The base material includes fluorocarbon resin; the pigment includes mica, coral, cadmium red, iron blue and organic green; the filler includes wollastonite powder, qua...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com