Preparation method for reinforced polyvinylidene fluoride hollow fiber membrane

A polyvinylidene fluoride and fiber membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as needing improvement, fracture and damage, and affecting treatment effect, so as to reduce irreversible deposition and prolong service life The effect of increasing the lifespan and increasing the mechanical bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

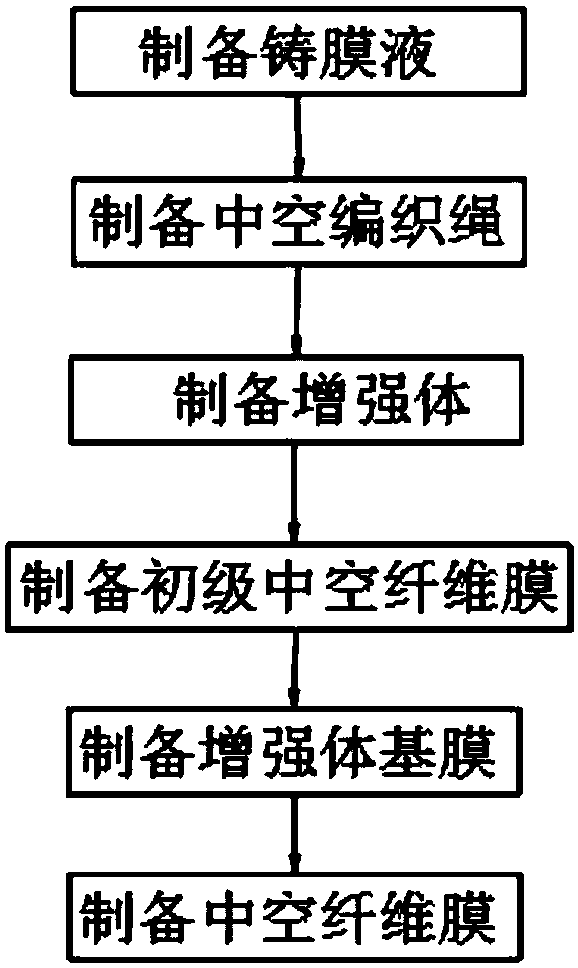

[0023] Example: such as figure 1 Shown, the present invention provides a kind of preparation method of reinforced polyvinylidene fluoride hollow fiber membrane, comprises the steps:

[0024] 1) Preparation of casting solution: mix polyvinylidene fluoride, inorganic additives, porogen, coupling agent, initiator and solvent, and then ultrasonically disperse at 60-80°C for 30-60min to obtain a solution; add organic additives to In the solution, stir to dissolve, specifically stir at 60-80°C at a stirring speed of 200-400r / min for 8h, then raise the temperature to 80-90°C and stir for 2-5h, then cool down to 70-80°C and stir for 6-10 hours, After filtering and defoaming, the casting solution is obtained;

[0025] 2) Preparation of hollow braided rope: under the condition of 30-80°C, soak the hollow braided rope with a mass concentration of 10% sodium hydroxide aqueous solution for 0.5h-1h to remove the oil stain on the surface, take it out and wash it with water and dry it for la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com