Preparation method for self-support ferrocobalt phosphide nanosphere electrocatalyst

A cobalt iron phosphide, nano-microsphere technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of high cost, scarcity, application limitations, etc. Effects of transport, low cost, good stability and catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

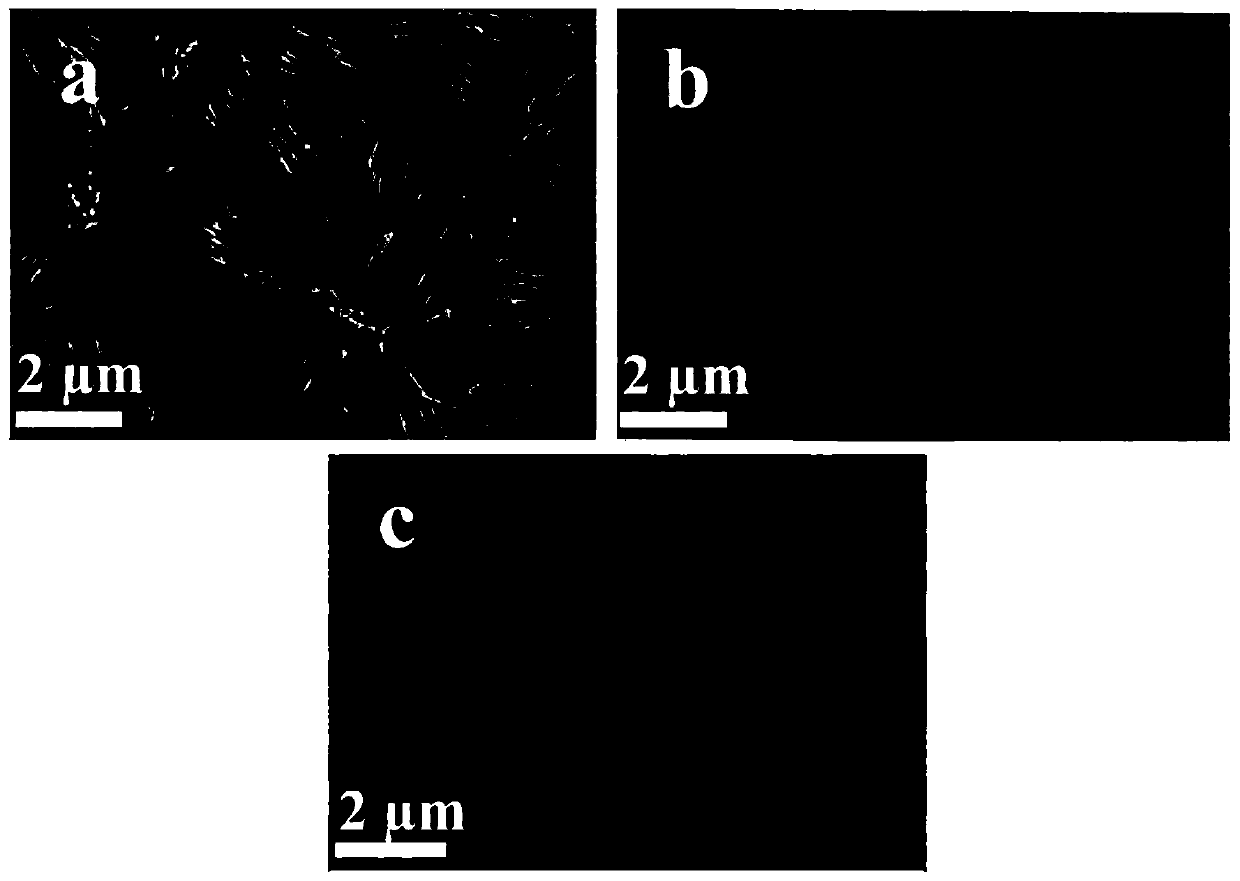

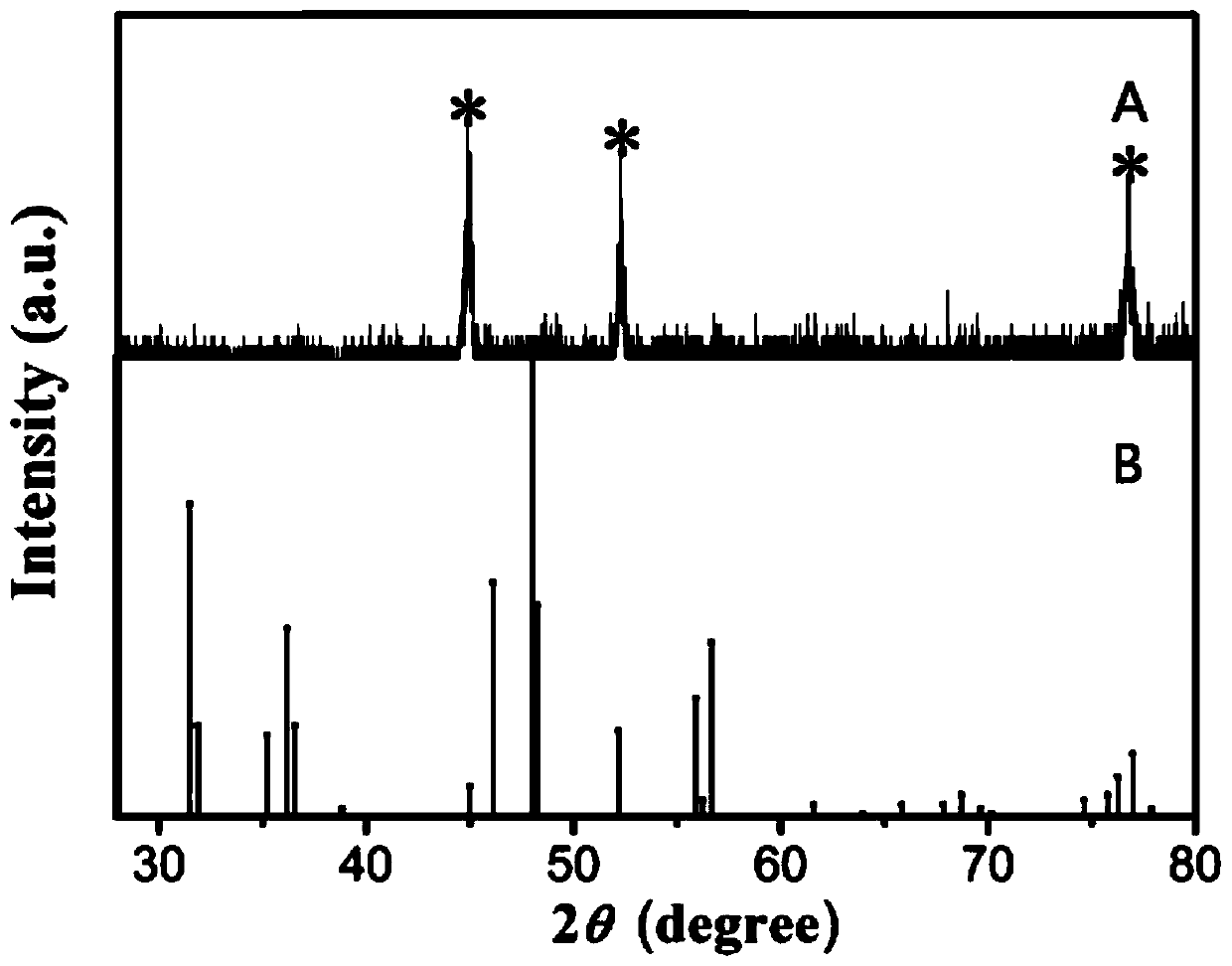

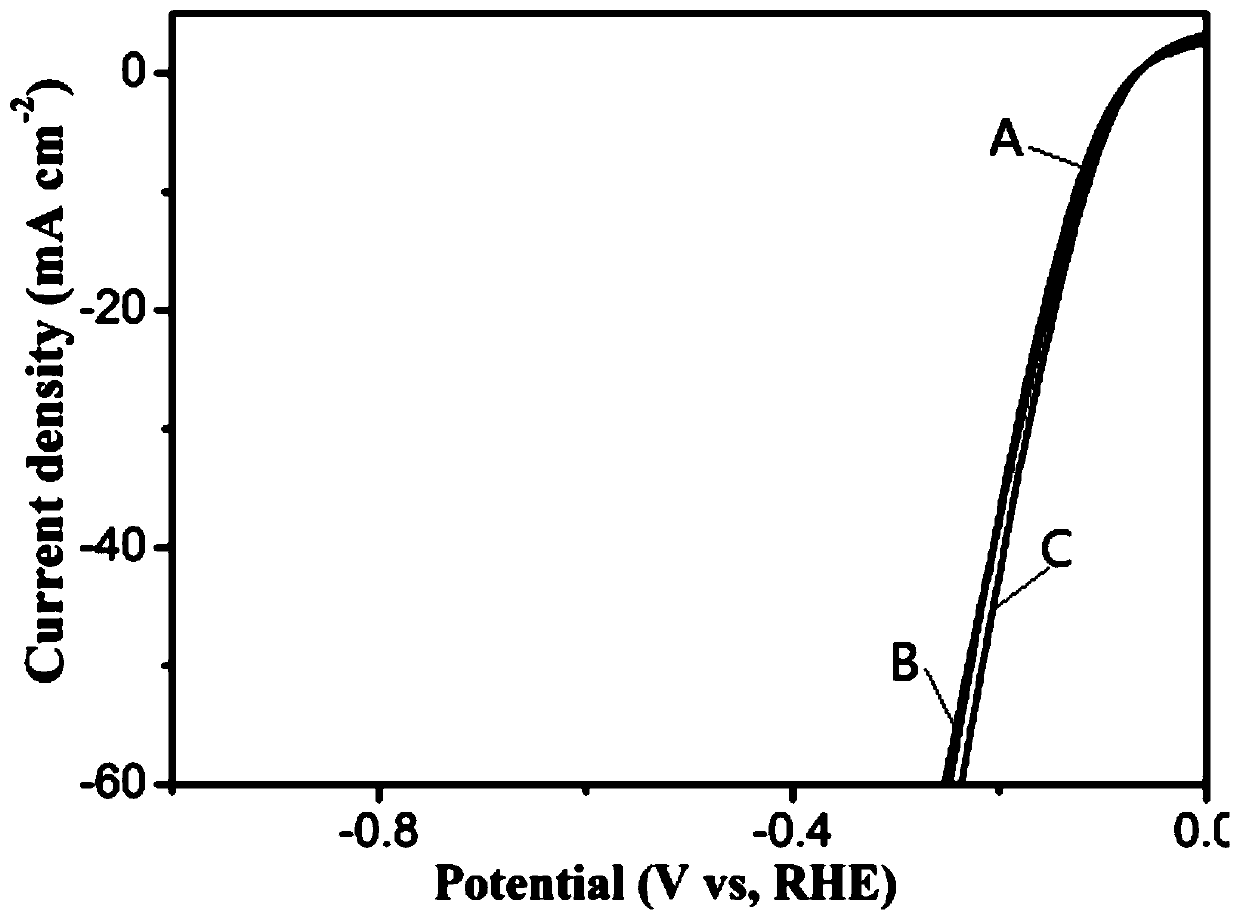

[0017] Specific embodiment one: a kind of preparation method of self-supporting cobalt iron phosphide nano microsphere electrocatalyst of the present embodiment is characterized in that the preparation method comprises the following steps:

[0018] 1. Treatment of foamed nickel: First, cut the foamed nickel into 1×1.5cm, place it in hydrochloric acid solution for ultrasonic treatment, then place it in acetone for ultrasonic treatment, then place it in water for ultrasonic treatment, and then immerse it in ethanol. use;

[0019] 2. Weigh cobalt chloride hexahydrate, ferric chloride hexahydrate, ammonium fluoride and urea, first mix cobalt chloride hexahydrate, ammonium fluoride and urea for 20-40 minutes, then add ferric chloride hexahydrate Stir for 8-12 hours to obtain a mixed reagent, stir at room temperature to obtain a homogeneous solution;

[0020] 3. Immerse the nickel foam treated in step 1 into the homogeneous solution obtained in step 2, and add it to the reaction ke...

specific Embodiment approach 2

[0023] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the molar ratio of sodium hypophosphite to cobalt chloride hexahydrate is 5:1. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0024] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the molar ratio of cobalt chloride hexahydrate, ferric chloride hexahydrate, ammonium fluoride and urea is 1:2:5:10. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com