Waterborne paint for car chassis protection and preparation method thereof

An automotive chassis, water-based technology, used in antifouling/underwater coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve the problems of wear, adhesion and antibacterial properties to be improved, shorten production time, thermal expansion The effect of reducing the coefficient and improving the sterilization performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

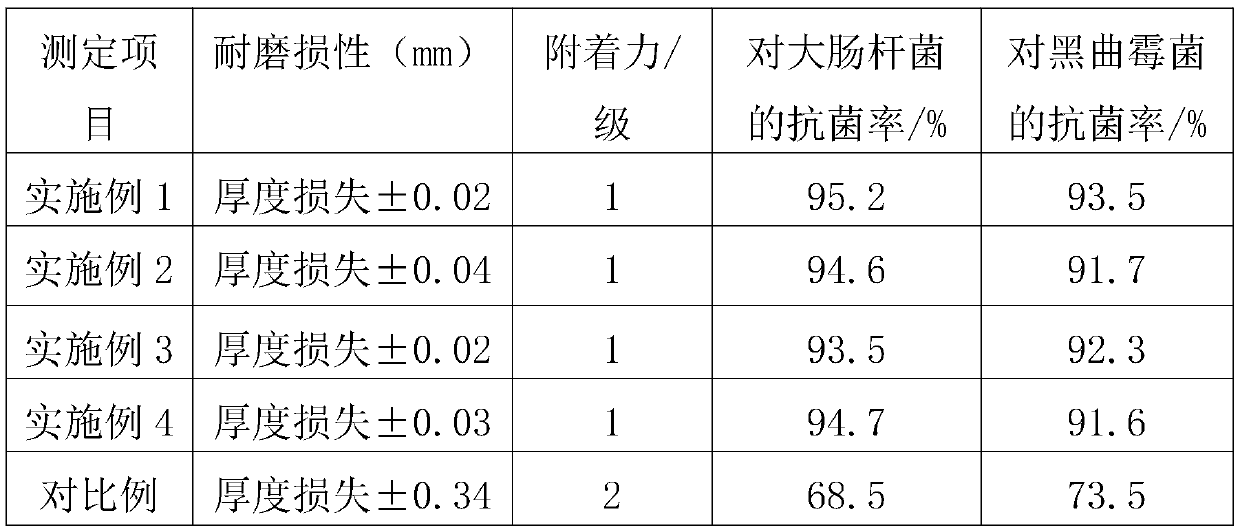

Examples

Embodiment 1

[0025] A water-based coating for automobile chassis protection, which is composed of the following raw material components in parts by mass: 65 parts of water-soluble epoxy acrylic resin, 30 parts of polyacrylate emulsion, 17 parts of zinc isooctanoate, 8 parts of sodium alginate, six sub- 14 parts of methyl diisocyanate, 10 parts of nano-silicon carbide, 17 parts of talc powder, 13 parts of hydroxyethyl methacrylate phosphate, 12 parts of tourmaline powder, 8 parts of negative ion powder, 5.5 parts of anti-rust pigment, 1.5 parts of dispersant , 2.0 parts of film-forming aid, 2.0 parts of leveling agent, 2.0 parts of defoamer and 17 parts of deionized water.

[0026] The antirust pigment is zinc phosphate.

[0027] The dispersant is triethylhexyl phosphoric acid.

[0028] The film-forming aid is selected from propylene glycol methyl ether acetate.

[0029] The leveling agent is ethylene glycol monobutyl ether.

[0030] The defoamer is polyoxypropylene glyceryl ether.

[0...

Embodiment 2

[0039] A water-based coating for automobile chassis protection, which is composed of the following raw material components in parts by mass: 60 parts of water-soluble epoxy acrylic resin, 35 parts of polyacrylate emulsion, 15 parts of zinc isooctanoate, 10 parts of sodium alginate, six sub- 12 parts of methyl diisocyanate, 12 parts of nano-silicon carbide, 15 parts of talc powder, 15 parts of hydroxyethyl methacrylate phosphate, 10 parts of tourmaline powder, 8.5 parts of negative ion powder, 5 parts of antirust pigment, 1.6 parts of dispersant , 1.8 parts of film-forming aid, 2.2 parts of leveling agent, 1.8 parts of defoamer and 20 parts of deionized water.

[0040] Zinc yellow is selected as the anti-rust pigment.

[0041] The dispersant is fatty acid polyethylene glycol ester.

[0042] The film-forming aid is selected from propylene glycol methyl ether acetate.

[0043] The leveling agent is acrylic acid copolymer.

[0044] The defoamer is polyoxyethylene polyoxypropylene...

Embodiment 3

[0053] A water-based coating for automobile chassis protection, which is composed of the following raw material components in parts by mass: 75 parts of water-soluble epoxy acrylic resin, 38 parts of polyacrylate emulsion, 20 parts of zinc isooctanoate, 12 parts of sodium alginate, six sub- 18 parts of methyl diisocyanate, 13 parts of nano-silicon carbide, 20 parts of talcum powder, 17 parts of hydroxyethyl methacrylate phosphate, 15 parts of tourmaline powder, 9 parts of negative ion powder, 7 parts of anti-rust pigment, 1.7 parts of dispersant , 2.4 parts of film-forming aid, 2.4 parts of leveling agent, 2.5 parts of defoamer and 23 parts of deionized water.

[0054] The antirust pigment is zinc phosphate.

[0055] The dispersant is triethylhexyl phosphoric acid.

[0056] The film-forming aid is selected from propylene glycol methyl ether acetate.

[0057] The leveling agent is ethylene glycol monobutyl ether.

[0058] The defoamer is polyoxypropylene glyceryl ether.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com