Lithium-based negative electrode material for solid-state battery, and preparation method and application thereof

A negative electrode material and solid-state battery technology, applied in battery electrodes, electrolyte storage battery manufacturing, secondary batteries, etc., can solve problems such as difficult large-scale production, difficult promotion, complex process, etc., to achieve wide application, increase the limit current density, promising effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] In a high-purity argon atmosphere, according to the ratio of the mass content of metallic lithium to 60%, the battery-grade pure lithium metal and commercial graphite are mixed together in a high-temperature stirrer, and the metallic lithium is melted after the temperature is heated to 280°C. , control the constant temperature, under the mechanical stirring of the stainless steel stirrer, the rotating speed is 60r / min, and the time is 30min. After the constant temperature stirring is completed, adjust the stirring speed to 5 r / min and stir slowly.

[0040] Heat the lithium lanthanum zirconium oxide thin ceramic sheet to 280°C, and after the temperature reaches 280°C, uniformly coat the stirred lithium-graphite mixture on the ceramic sheet, and cool down to room temperature.

[0041] The amount of coating on the ceramic sheet is 1.5 mg / cm in terms of the coated lithium-graphite composite powder 2 .

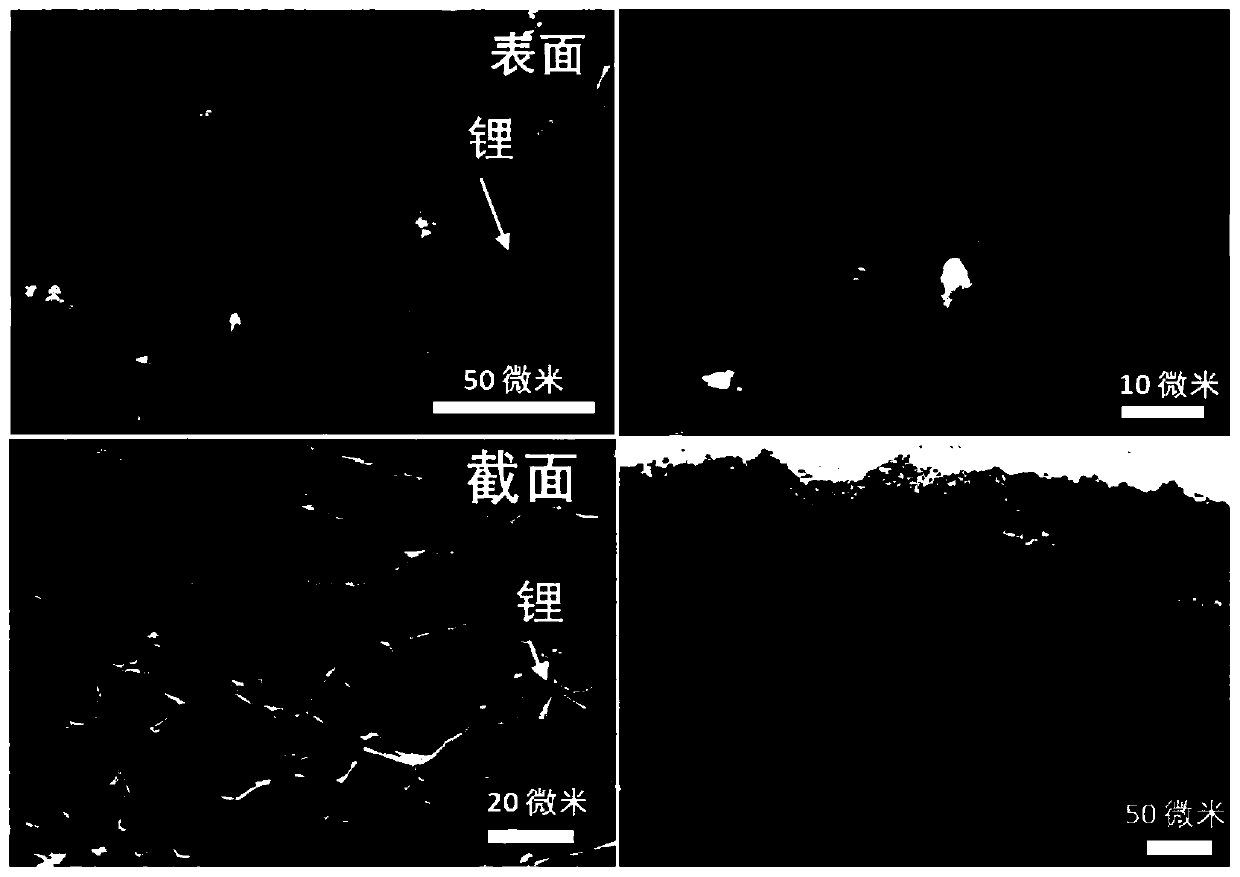

[0042] figure 1 Be the SEM collection of illustrative plates of lith...

Embodiment 2

[0051] In a high-purity argon atmosphere, according to the ratio of the mass content of lithium metal to 90%, lithium metal with battery-grade purity and commercial carbon nanotubes are mixed, placed together in a high-temperature stirrer, and heated to 310°C to make lithium metal After melting, control the constant temperature, under the action of mechanical stirring of the stainless steel stirrer, the rotating speed is 80r / min, and the time is 40min. After the constant temperature stirring is completed, the heat supply of the high temperature stirrer is stopped, so that the lithium composite negative electrode material is gradually cooled to room temperature.

[0052] The composite material is rolled and thinned by a roller press in advance, and then the porous copper foil is used as a metal current collector, and the thinned lithium composite negative electrode material is transferred to the porous copper foil.

[0053] The selected porous copper foil is 200 mesh, the thick...

Embodiment 3

[0056] Commercialized graphite and commercialized carbon nanotubes were mixed according to the mass content of carbon nanotubes at a ratio of 5%, and then placed in a high-energy ball milling tank for mechanical ball milling (rotational speed 300r / min, time 1.5h), and ball milling was completed and taken out for use.

[0057] In a high-purity argon atmosphere, according to the ratio of the mass content of lithium metal to 80%, lithium metal of battery grade purity and the above-mentioned premix of graphite and carbon nanotubes are mixed, placed together in a high-temperature stirrer, and heated to After metal lithium is melted at 350°C, the temperature is controlled, and under the action of mechanical stirring of a stainless steel stirrer, the rotation speed is 100r / min, and the time is 50min. After the constant temperature stirring is completed, adjust the stirring speed to 5 r / min and stir slowly.

[0058] Heat the lithium lanthanum zirconium oxide thin ceramic sheet to 220°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Limiting current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com