Carbon-supported transition metal phosphide electrocatalyst for hydrogen generation and preparation method of carbon-supported transition metal phosphide electrocatalyst

A technology of transition metals and electrocatalysts, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, electrodes, etc., can solve the problems of poor charge transport and stability, complicated preparation process, low industrial adaptability, etc., and achieve high conductivity , good electrical conductivity, simple and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

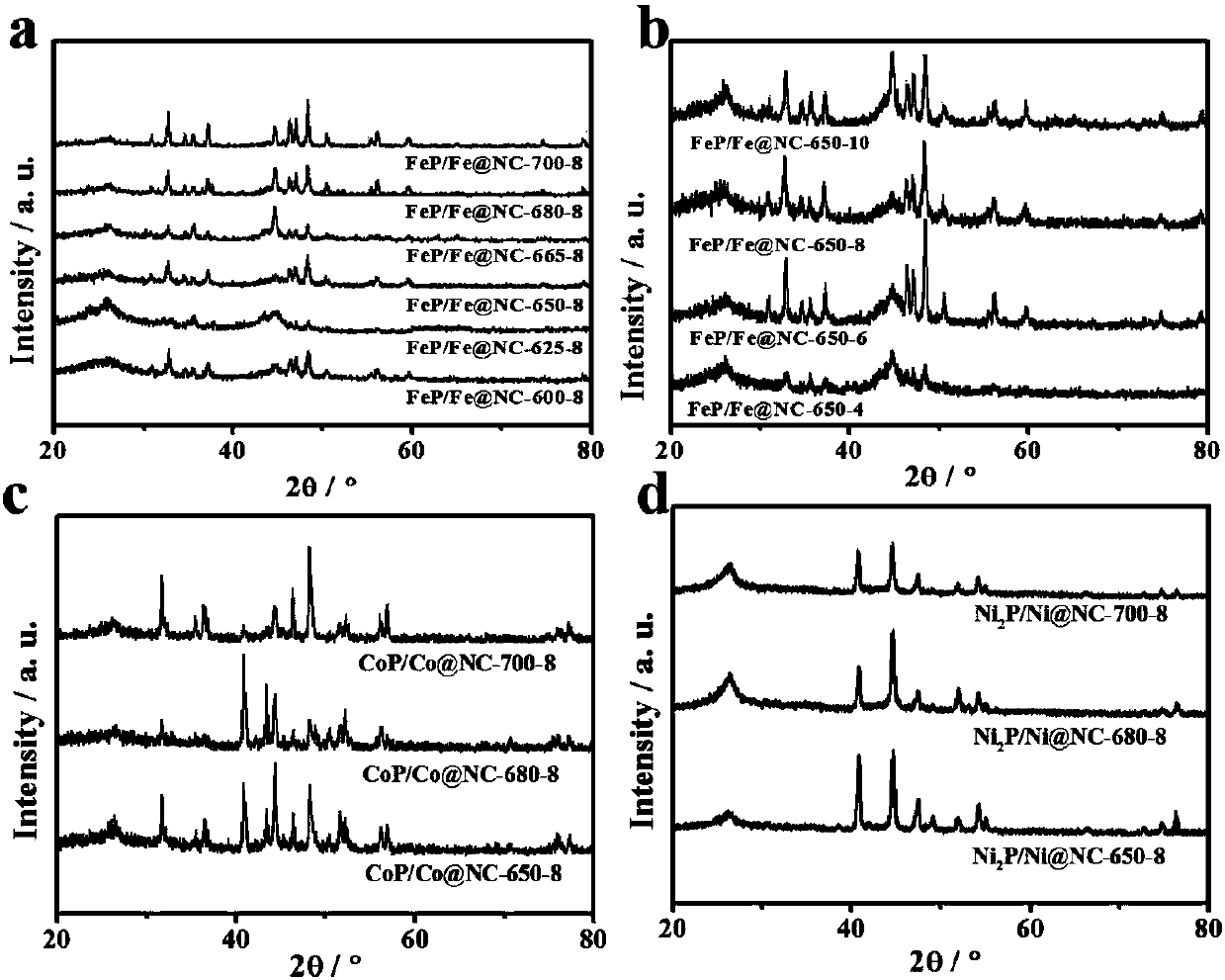

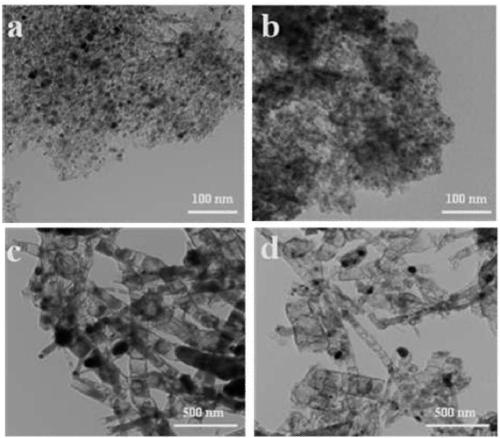

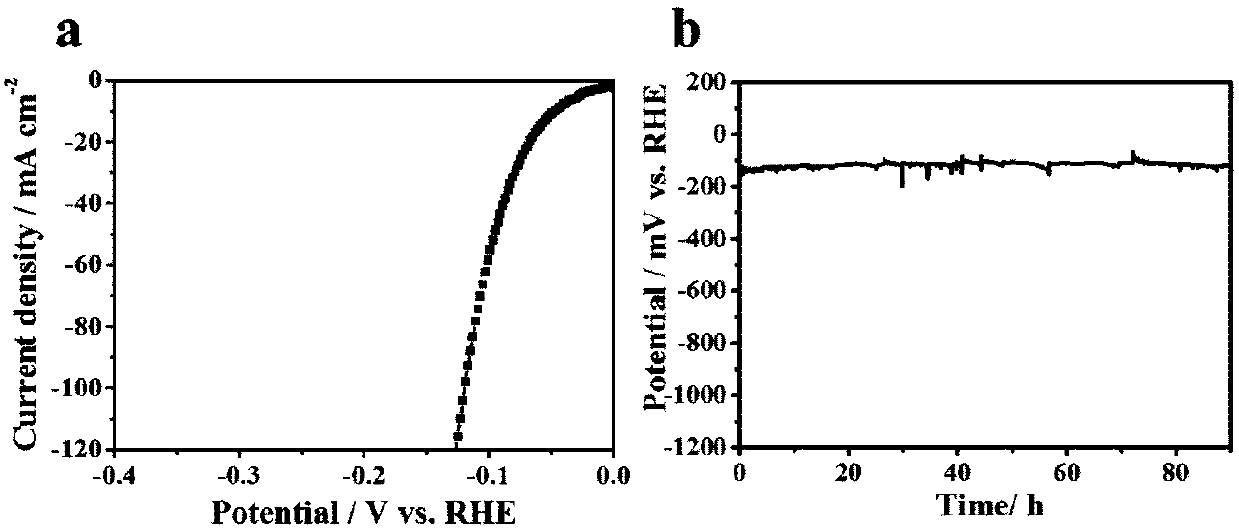

[0030] This embodiment illustrates the preparation of carbon-supported iron phosphide (FeP / Fe@NC) catalyst and the control example of heat treatment temperature (T):

[0031] Adopt ferric ammonium citrate and dicyandiamide as raw material, according to dicyandiamide: the mass ratio of ferric ammonium citrate=8:1 feeds intake, 8.0g dicyandiamide and 1.0g ferric ammonium citrate are dispersed in deionized water, in Stir in a water bath, evaporate to dryness, and grind to obtain a mixed powder. Next, put the mixed powder into a quartz tube, heat it to 600, 625, 650, 665, 680, and 700°C in an argon atmosphere at a heating rate of 10°C / min, react for 2 hours, and cool down to room temperature naturally to obtain a A series of iron-containing carbon precursors (Fe / Fe@NC-T-8) at different heat treatment temperatures;

[0032] Mix the prepared precursor and sodium hypophosphite at the ratio of Fe:P=1:5 (atomic ratio), grind them evenly, put them into a tube furnace and perform phosph...

Embodiment 2

[0037]This embodiment illustrates the control example of the reactant ratio (X) prepared by carbon-supported iron phosphide (FeP / Fe@NC) catalyst:

[0038] Ferric ammonium citrate and dicyandiamide are used as raw materials, and the feeding ratio of the two is adjusted to dicyandiamide: ferric ammonium citrate=4:1, 6:1, 8:1, 10:1 (mass ratio). The feeding amount of fixed dicyandiamide was 8.0g, and the corresponding mass of ferric ammonium citrate was added, and then the mixture was dispersed in deionized water, stirred and evaporated to dryness in a water bath, and mixed powder was obtained after grinding. Next, put the mixed powder into a quartz tube, heat up to 650°C at a rate of 10°C / min in an argon atmosphere, and cool down to room temperature naturally to obtain a series of iron-containing carbon precursors with different reactant ratios (Fe / Fe@NC-650-X);

[0039] Mix the prepared precursor and sodium hypophosphite at the ratio of Fe:P=1:5 (atomic ratio), grind them eve...

Embodiment 3

[0042] This embodiment illustrates the preparation of carbon-supported cobalt phosphide (CoP / Co@NC) catalyst and the control example of heat treatment temperature (T):

[0043] Adopting cobalt acetate and dicyandiamide as raw material, according to dicyandiamide: the mass ratio of cobalt acetate=8:1 feeds intake, 8.0g dicyanamide and 1.0g cobalt acetate are dispersed in deionized water, stirred and evaporated to dryness in a water bath, Grind to obtain a mixed powder. Next, put the mixed powder into a quartz tube, raise the temperature to 650, 680, and 700°C at a rate of 10°C / min in an argon atmosphere, and cool down to room temperature naturally to obtain a cobalt-containing carbon precursor (Co / Co@ NC-T-8);

[0044] Mix the prepared precursor and sodium hypophosphite in the ratio of Co:P=1:5 (atomic ratio), grind them evenly, put them into a tube furnace and perform phosphating treatment in an argon atmosphere at 5°C / min The heating rate was raised to 500 °C and kept for 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com