Method using liquid drop self-bounce effect to improve atmospheric corrosion protective property of sample

A technology of atmospheric corrosion and protective performance, applied to the device for coating liquid on the surface, pretreatment surface, coating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Preparation of super-hydrophobic surface: In this embodiment, the two-step method of hydrothermal reaction and surface modification is used to prepare two kinds of super-hydrophobic surfaces on zinc flakes by controlling the concentration of reactants.

[0032] (1) Cutting and cleaning of zinc flakes. Cut the zinc sheet into 3×1.5cm 2 The size, followed by ultrasonic cleaning with absolute ethanol and ultrapure water, followed by drying with nitrogen for use.

[0033] (2) Hydrothermal reaction. Method ①: Add 0.10M zinc acetate and equimolar hexamethylenetetramine into 70mL ultrapure water, then add 2.33mL ammonia water drop by drop under vigorous stirring, mix well and transfer to vertical place with zinc flakes in step (1) After sealing, heat at 90°C for 5H. After the reaction kettle is naturally cooled to room temperature, the zinc flakes after the hydrothermal treatment are taken out and washed with ultrapure water and absolute ethanol in sequence, and dried with nitrog...

Embodiment 2

[0037] Condensation experiment:

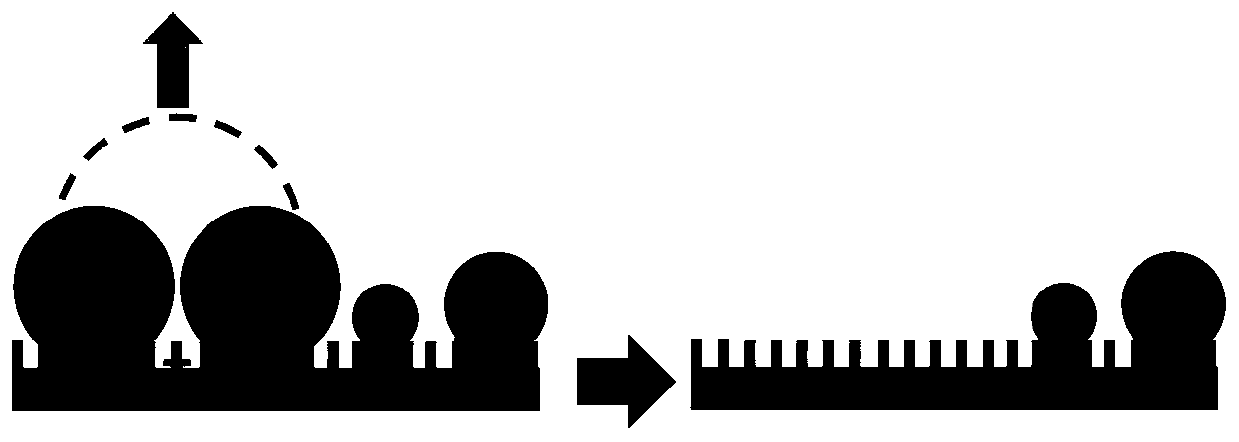

[0038] The condensation experiment was used to simulate the condensation process of the two superhydrophobic surfaces in the atmosphere in Example 1, and the spontaneous bouncing phenomenon of droplets on the superhydrophobic surfaces of different structures was observed with an optical microscope. Specifically: the superhydrophobic surface was placed horizontally On the supercooled copper block (~1℃), adjust the microscope instantly to take a picture of surface condensation every second, and the recording time lasts for 15 minutes. In this process, the relative humidity of the controlled environment is 65±3%, the environment temperature is 21±2°C, which corresponds to the dew point -15°C, and the supersaturation degree -2.6. The experimental results show that the nanostructured superhydrophobic surface droplets can bounce after merging, and the droplets formed on the surface are relatively sparse, while the microstructured superhydrophobic surfa...

Embodiment 3

[0040] Atmospheric corrosion protection mechanism based on the self-bouncing effect of superhydrophobic surface droplets:

[0041] The principle of total reflection of light is used to verify the existence of the air layer before and after the condensation of the superhydrophobic surfaces of the two structures, and the AC impedance and polarization curves are used to evaluate the atmospheric corrosion protection performance of the superhydrophobic surfaces of different structures before and after condensation. The experiment uses a three-electrode system, with Ag / AgCl (3M KCl) electrode as the reference electrode, platinum plate as the counter electrode, the superhydrophobic surface before and after condensation in Example 2 as the working electrode, and 3.5wt.% NaCl solution as the test solution , Carried out at room temperature (see Figure 3-Figure 5 ). Among them, the AC impedance test parameter is set to be measured under open circuit potential, the sine wave amplitude is 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com