Dry-and-wet combined preparation method of instant corn nutrition snowflake tablets

A snow flakes, combined technology, applied in the field of preparation of instant corn nutritional snow flakes, can solve the problems of reducing the content of reducing sugar and free amino acids, affecting the gelatinization characteristics of starch, affecting the brewability of products, etc., to improve the brewability , retain nutrients and flavor substances, easy to control the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] In the present embodiment, the process steps of preparing instant corn nutritional snow flakes are as follows:

[0038] (1) Dry puffing powder making

[0039] The dry corn grits are crushed with a pulverizer and passed through a 20-mesh sieve, and then the corn flour obtained by sieving is prepared by adding tap water to moisten the corn flour. The amount of tap water added is 3.5% of the weight of the corn flour, and then the prepared corn flour The corn flour is fed into the twin-screw extrusion extruder, extruded and expanded at 180°C and 0.8MPa, and then the extruded and expanded product is pulverized with a pulverizer, passed through a 20-mesh sieve, and the expanded corn obtained by sieving The flour is subjected to magnetic separation to obtain puffed corn flour that meets the requirements;

[0040] (2) Soak dried corn grits

[0041] Measure 50 parts by weight of dry corn grits that have no mildew, no peculiar smell, no insects, and normal color, put them into ...

Embodiment 2

[0055] In the present embodiment, the process steps of preparing instant corn nutritional snow flakes are as follows:

[0056] (1) Dry puffing powder making

[0057] The dry corn grits are crushed with a pulverizer and passed through a 20-mesh sieve, and then the corn flour obtained by sieving is prepared by adding distilled water to moisten the corn flour. The amount of distilled water added is 3.6% of the weight of the corn flour, and then the prepared corn flour The corn flour is fed into the twin-screw extrusion extruder, extruded and expanded at 160°C and 0.9 MPa, and then the extruded and expanded product is pulverized with a pulverizer, passed through a 20-mesh sieve, and the expanded corn obtained by sieving The flour is subjected to magnetic separation to obtain puffed corn flour that meets the requirements;

[0058] (2) Soak dried corn grits

[0059] Measure 70 parts by weight of dry corn grits without mildew, no peculiar smell, no insects, and normal color, put it...

Embodiment 3

[0073] In the present embodiment, the process steps of preparing instant corn nutritional snow flakes are as follows:

[0074] (1) Dry puffing powder making

[0075] Add dry corn grits with 4% of its weight in tap water, and expand it with an air-flow expander under a pressure of 0.8 MPa, then grind the expanded product with a pulverizer, pass through a 20-mesh sieve, and perform the puffing of the expanded corn flour obtained by sieving. Magnetic separation to obtain puffed corn flour that meets the requirements;

[0076] (2) Soak dried corn grits

[0077] Measure 60 parts by weight of dry corn grits without mildew, no peculiar smell, no insects, and normal color, put it into a jacketed pot, add 120 parts by weight of tap water at 30°C to soak for 4 hours, and then remove the soaking water;

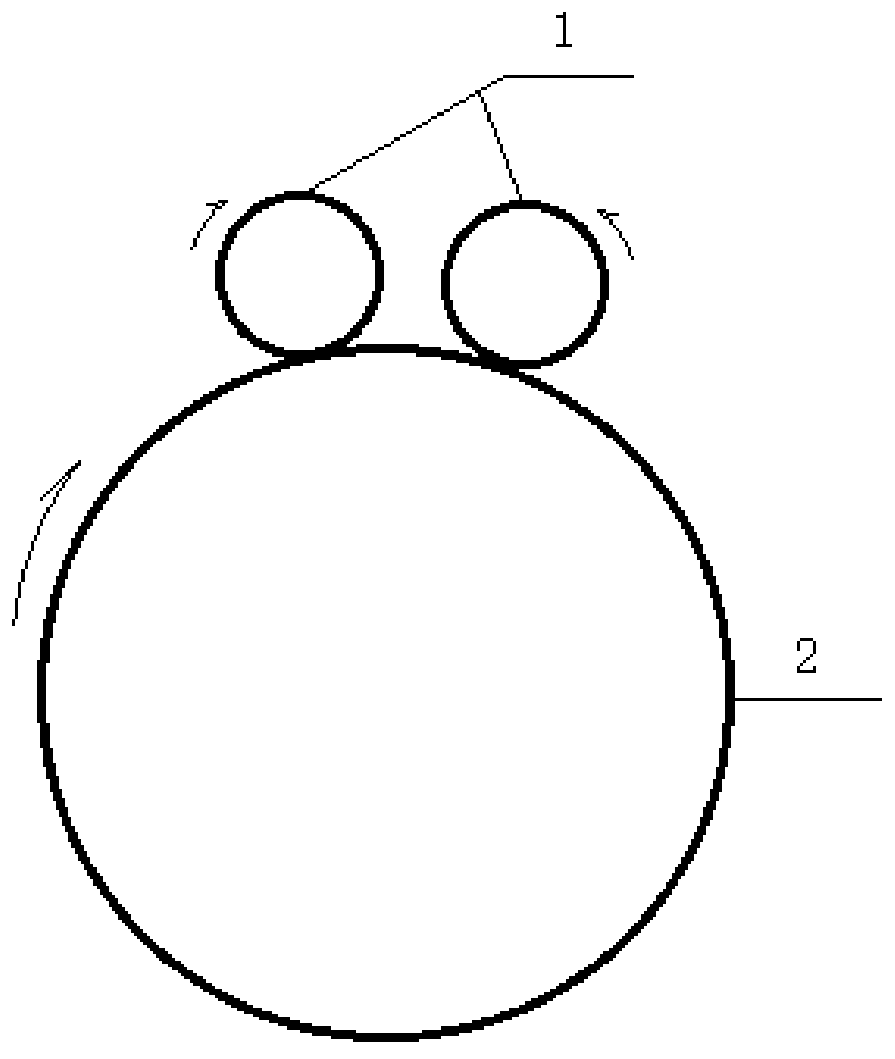

[0078] (3) Refining

[0079] Measure 40 parts by weight of the puffed corn flour prepared in step (1), send it to the colloid mill feeding hopper together with the corn grits soaked i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap