Soil remediation agent with tea heavy metal content reducing function and use method of soil remediation agent

A soil remediation agent and heavy metal technology, which is applied in the field of tea soil, can solve problems affecting the quality of tea, reduce the concentration of heavy metals in the soil, improve the quality, and optimize the soil structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

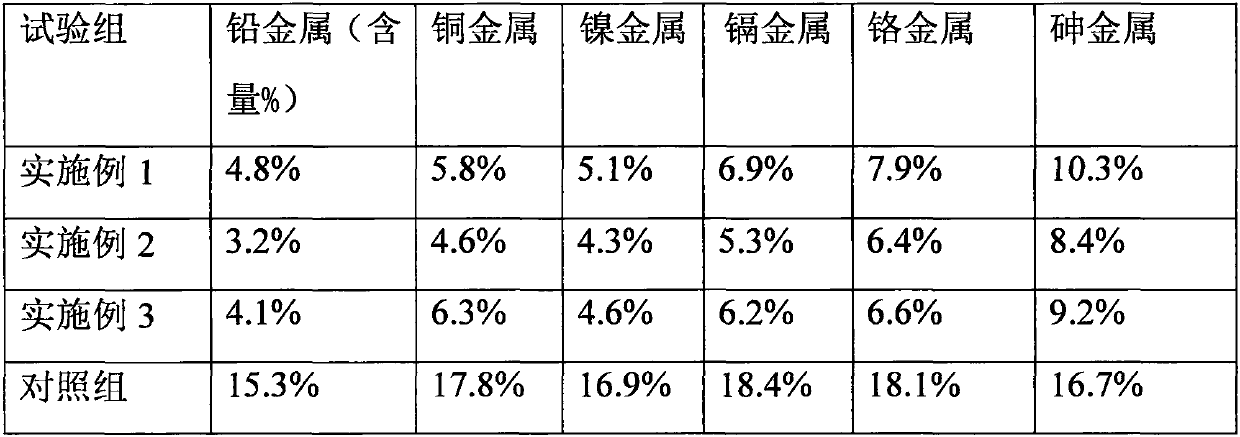

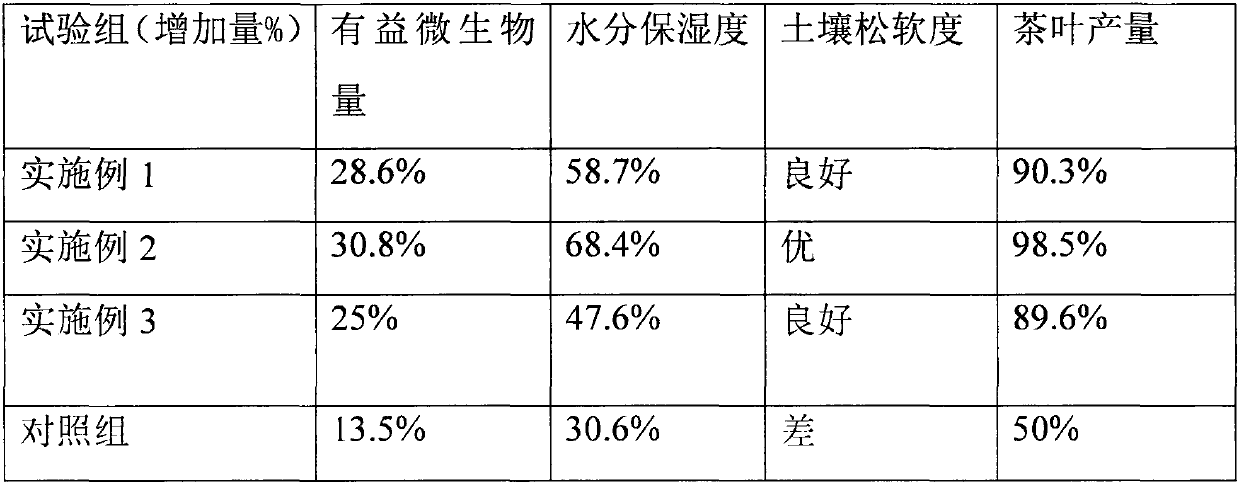

Examples

preparation example Construction

[0030] A method for preparing soil remediation agent for reducing heavy metal content in tea leaves, characterized in that: the specific steps are as follows;

[0031] Step 1: Select and mix materials, select slaked lime, sodium bentonite, magnesium carbonate, ferric sulfate and blast furnace slag, put them in a mixer and stir for 20 minutes to make them fully mixed, then put them into a grinder for four times of grinding to get powdery particles and put them into Carry out heating and heating in the reactor for 30 minutes, the temperature is 30-45 degrees Celsius;

[0032] Step 2: Add an appropriate amount of deionized water to the reaction kettle, stir at high speed for 30 minutes, then add polyvinyl chloride, humic acid, stabilizer, citric acid and pH regulator in turn, stir for 20 minutes, then raise the temperature to 50 degrees Celsius to keep warm 30 minutes;

[0033] Step 3: When the temperature of the reaction kettle drops to normal temperature, add organic fertilize...

Embodiment 1

[0036] Raw material formula: including 8 parts of slaked lime, 8 parts of sodium bentonite, 6 parts of polyvinyl chloride, 1 part of magnesium carbonate, 1 part of pH regulator, 6 parts of Bacillus subtilis, 1 part of photosynthetic bacteria, 1 part of humic acid, stabilizer Agent 8, 1 part of high iron sulfate, 1 part of blast furnace slag, 1 part of citric acid, 5 parts of soil conditioner and 5 parts of organic fertilizer compound.

[0037] Specific steps are as follows:

[0038] Step 1: Select and mix materials, select slaked lime, sodium bentonite, magnesium carbonate, ferric sulfate and blast furnace slag, put them in a mixer and stir for 20 minutes to make them fully mixed, then put them into a grinder for four times of grinding to get powdery particles and put them into Carry out heating and heating in the reactor for 30 minutes, the temperature is 30-45 degrees Celsius;

[0039] Step 2: Add an appropriate amount of deionized water to the reaction kettle, stir at high...

Embodiment 2

[0043] Raw material formula: including 9 parts of slaked lime, 10 parts of sodium bentonite, 7 parts of polyvinyl chloride, 3 parts of magnesium carbonate, 3 parts of pH regulator, 7 parts of Bacillus subtilis, 1.5 parts of photosynthetic bacteria, 3 parts of humic acid, stabilizer 9. 3 parts of high iron sulfate, 3 parts of blast furnace slag, 3 parts of citric acid, 6 parts of soil conditioner and 7 parts of organic fertilizer compound.

[0044] Specific steps are as follows:

[0045] Step 1: Select and mix materials, select slaked lime, sodium bentonite, magnesium carbonate, ferric sulfate and blast furnace slag, put them in a mixer and stir for 20 minutes to make them fully mixed, then put them into a grinder for four times of grinding to get powdery particles and put them into Carry out heating and heating in the reactor for 30 minutes, the temperature is 30-45 degrees Celsius;

[0046] Step 2: Add an appropriate amount of deionized water to the reaction kettle, stir at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com