Molecularly imprinted photonic crystal film for rapidly detecting lysozyme, and preparation method and application thereof

A photonic crystal and molecular imprinting technology, applied in the field of material chemistry and analysis and detection, can solve the problems of low selectivity, complicated sample pretreatment, time-consuming, etc., achieve low cost, reduce detection cost and operation requirements, and have good reusability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The specific preparation steps of the molecularly imprinted photonic crystal film for rapid detection of lysozyme of the present invention are as follows:

[0047] 1) After ultrasonically cleaning a 1×10×75 mm silicon wafer with deionized water, soak it in piranha solution (mixed solution of 98% concentrated sulfuric acid and 30% hydrogen peroxide, volume ratio 7:3) for 12 hours to remove surface impurities, After that, it was cleaned with deionized water and dried with nitrogen gas for later use;

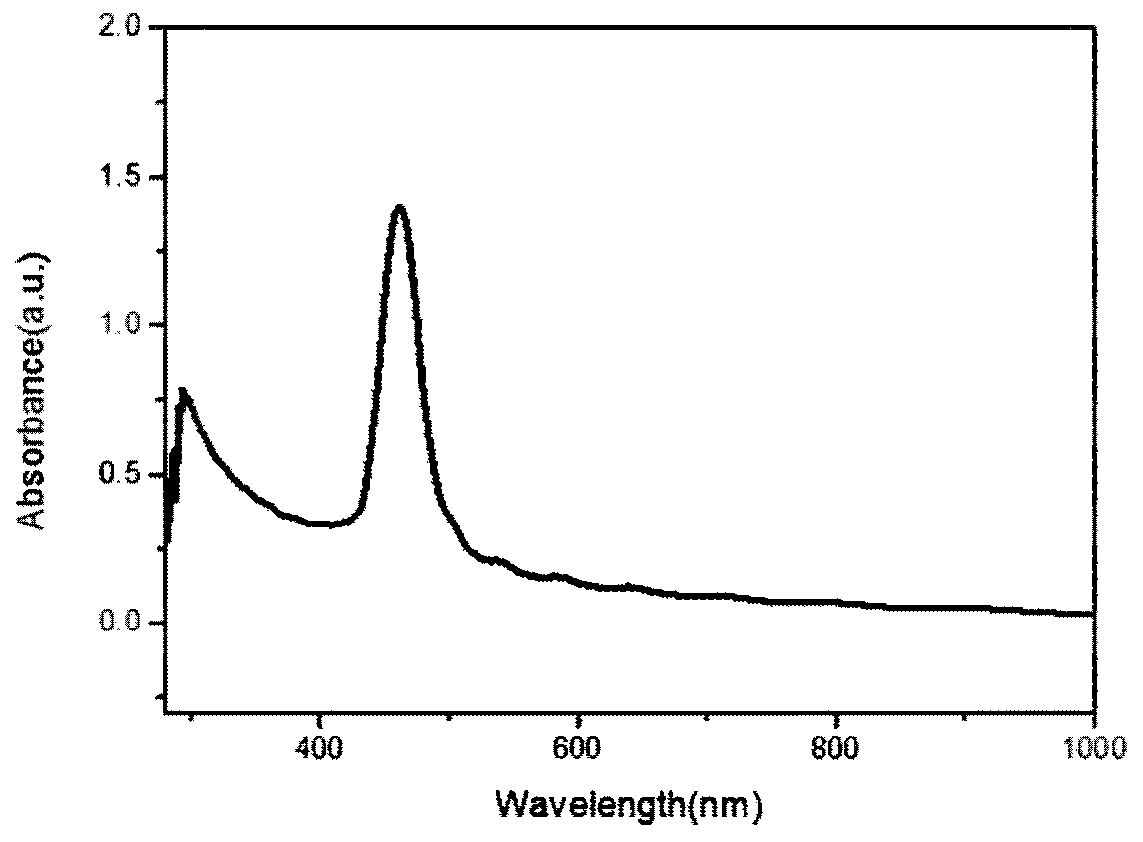

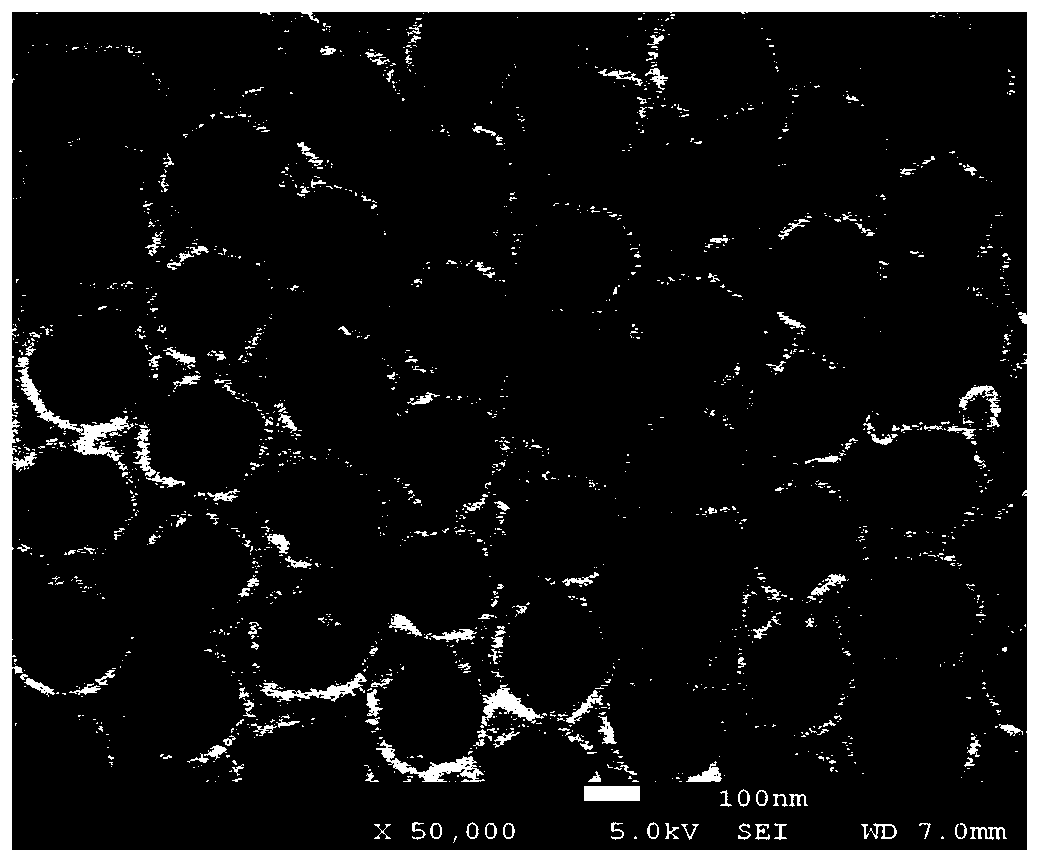

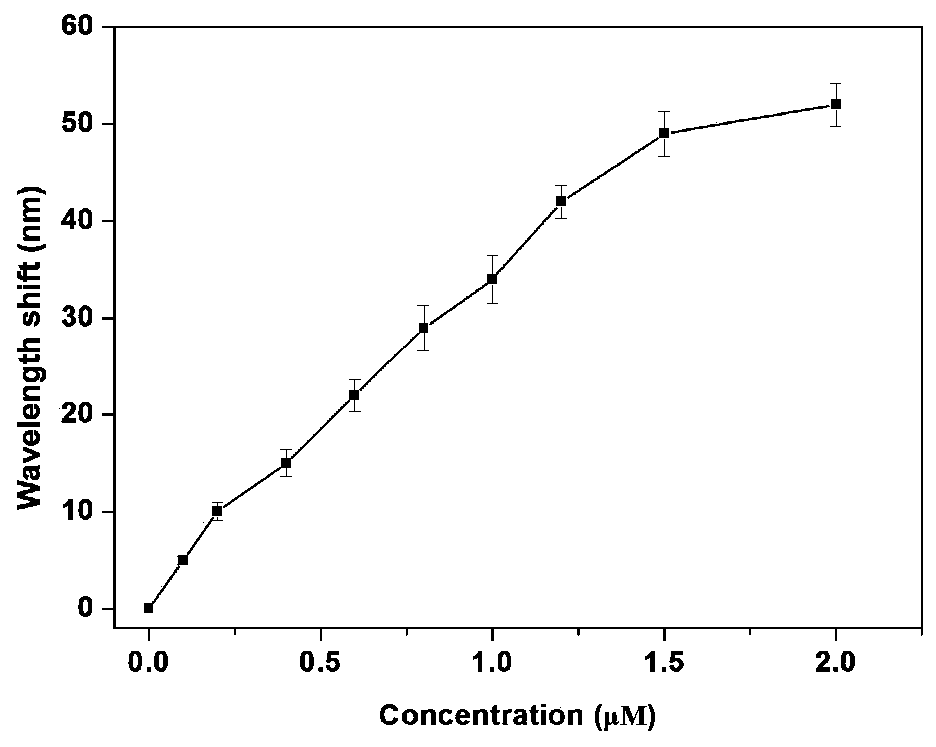

[0048] 2) Monodisperse silica (SiO2) with a particle size of 240nm 2 ) Microspheres are ultrasonically dispersed into absolute ethanol to form a colloidal dispersion system, in which SiO 2 With a mass fraction of 2.0%, the hydrophilized matrix prepared in step 1) was inserted into the silica microsphere solution at an angle of 45°, and vertically self-assembled, and left to stand at 35°C under constant temperature and airtight conditions until the ethanol was completely vol...

Embodiment 2

[0055] The specific preparation steps of the molecularly imprinted photonic crystal film for rapid detection of lysozyme of the present invention are as follows:

[0056] 1) After ultrasonically cleaning a 1×10×75 mm silicon wafer with deionized water, soak it in piranha solution (mixed solution of 98% concentrated sulfuric acid and 30% hydrogen peroxide, volume ratio 7:3) for 12 hours to remove surface impurities, Afterwards, it was cleaned with deionized water, and dried with nitrogen gas for subsequent use to obtain a hydrophilic matrix;

[0057] 2) Monodisperse silica (SiO2) with a particle size of 220nm 2 ) Microspheres are ultrasonically dispersed into absolute ethanol to form a colloidal dispersion system, in which SiO 2 The mass fraction is 3.0%, the hydrophilized matrix prepared in step 1) is inserted into the silica microsphere solution at an angle of 90°, and vertical self-assembly is adopted, and it is left to stand at 35°C under a constant temperature and airtigh...

Embodiment 3

[0064] The specific preparation steps of the molecularly imprinted photonic crystal film for rapid detection of lysozyme of the present invention are as follows:

[0065] 1) After ultrasonically cleaning a 1×10×75 mm silicon wafer with deionized water, soak it in piranha solution (mixed solution of 98% concentrated sulfuric acid and 30% hydrogen peroxide, volume ratio 7:3) for 12 hours to remove surface impurities, After that, it was cleaned with deionized water and dried with nitrogen gas for later use;

[0066] 2) Monodisperse silica (SiO2) with a particle size of 220nm 2 ) Microspheres are ultrasonically dispersed into absolute ethanol to form a colloidal dispersion system, in which SiO 2 With a mass fraction of 2.0%, the hydrophilized matrix prepared in step 1) was inserted into the silica microsphere solution at an angle of 45°, and vertically self-assembled, and left to stand at 35°C under constant temperature and airtight conditions until the ethanol was completely vol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com