Preparation method for WO3/CuWO4/NiFe LDH ternary composite photoelectrode film

A ternary composite, photoelectrode technology, applied in electrodes, electrolysis process, electrolysis components, etc., can solve problems such as poor stability, and achieve the effect of reducing energy barrier, slowing attenuation, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A kind of WO 3 / CuWO 4 / NiFe LDH ternary composite photoelectrode thin film preparation method, the specific steps are as follows:

[0018] Prepare 15ml of sodium tungstate solution with a concentration of 25mmol / L, and add 5ml of hydrochloric acid (3mol / L) dropwise; prepare 15ml of an aqueous ammonium oxalate solution with a concentration of 55mmol / L, slowly add it to the sodium tungstate solution, and stir for 30min; transfer the mixture To the lining of the hydrothermal reactor, the FTO glass is washed with water, ethanol and acetone, N 2 Flow down and blow dry, place the FTO with the conductive side facing down, and place it in the inner lining of the reaction kettle, and conduct a hydrothermal reaction at 140°C for 6 hours; take it out, wash it with water three times, dry it at 25°C, and place it in a muffle furnace for calcination at 500°C for 2 hours ; Dissolve copper nitrate in acetic acid solution with a concentration of 50 mmol / L, pipette 100 μL of the solut...

Embodiment 2

[0021] A kind of WO 3 / CuWO 4 / NiFe LDH ternary composite photoelectrode film preparation method, the experimental steps are the same as in Example 1, changing the copper nitrate concentration to 20mmol / L, pipetting 100 μL of this solution with a pipette, and adding it dropwise to WO 3 On the membrane electrode, repeat this operation 3 times; Configuration 50ml concentration is the ferric nitrate of 5mmol / L and concentration is the nickel nitrate solution of 2mmol / L, the WO 3 / CuWO 4 As a working electrode, deposit at -1.1V potential for 30s, take out the working electrode, wash with water, and dry in the air to obtain WO 3 / CuWO 4 / NiFeLDH ternary composite photoelectrode.

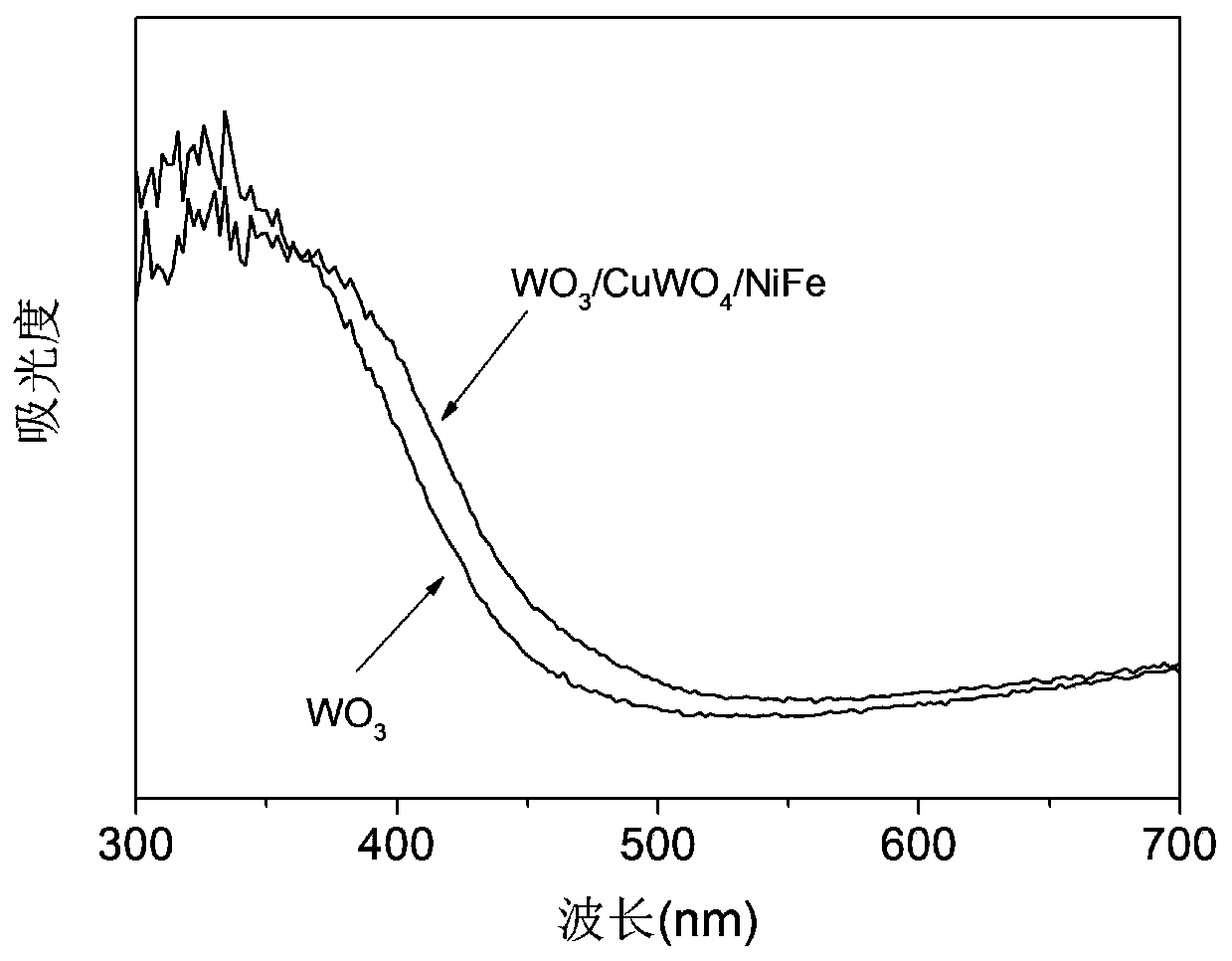

[0022] figure 2 for WO 3 and WO 3 / CuWO 4 / NiFe LDH thin-film electrode UV-Vis diffuse reflectance map for pure phase WO 3 , its band-edge absorption position appears at 450nm, and the calculated band gap is about 2.65eV. in WO 3 After the introduction of copper tungstate and NiFe LDH on the e...

Embodiment 3

[0024] A kind of WO 3 / CuWO 4 / NiFe LDH ternary composite photoelectrode film preparation method, the experimental steps are the same as in Example 1, changing the copper nitrate concentration to 60mmol / L, pipetting 100 μL of this solution with a pipette, and adding it dropwise to WO 3 On the membrane electrode, repeat this operation 2 times; Configuration 50ml concentration is the ferric nitrate of 3mmol / L and concentration is the nickel nitrate solution of 10mmol / L, the WO 3 / CuWO 4 As a working electrode, deposit at -1.2V potential for 30s, take out the working electrode, wash with water, and dry in the air to obtain WO 3 / CuWO 4 / NiFeLDH ternary composite photoelectrode.

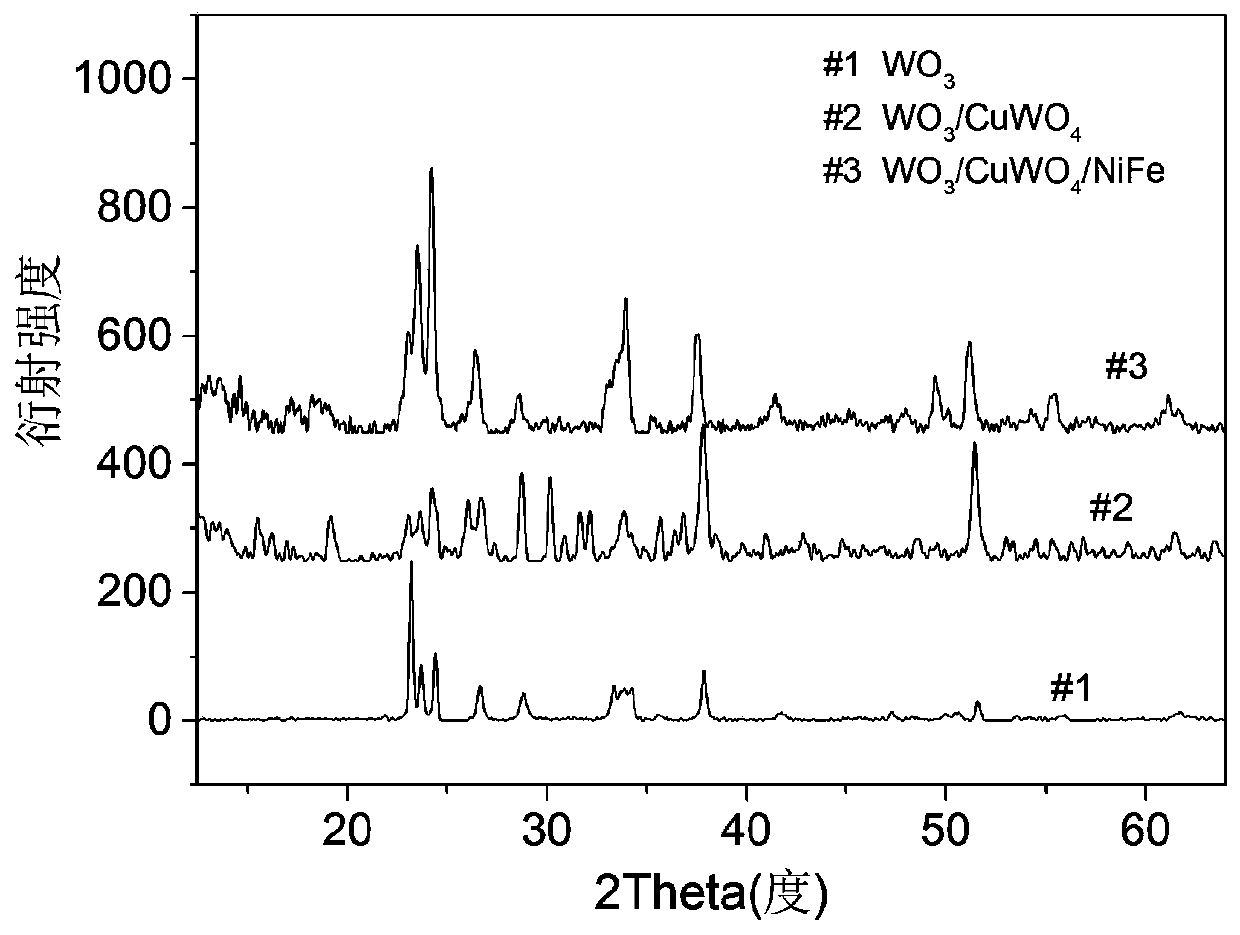

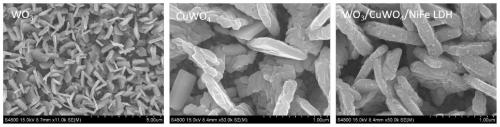

[0025] image 3 for WO 3 、WO 3 / CuWO 4 and WO 3 / CuWO 4 / NiFe LDH three electrode scanning electron microscope images, it can be seen that the morphology of the three electrodes is plate-like, but after calcining with the addition of copper ions, the surface of the plate-like structure becomes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com