Indium-arsenic-nitrogen-bismuth semiconductor material, laser using material, detector and preparation method

A technology of indium arsenic bismuth nitrogen and semiconductors, which is applied in the field of semiconductor photoelectric material preparation, can solve the problem of low solubility of N atoms, and achieve the effects of easy control, easy growth, simple structure and operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

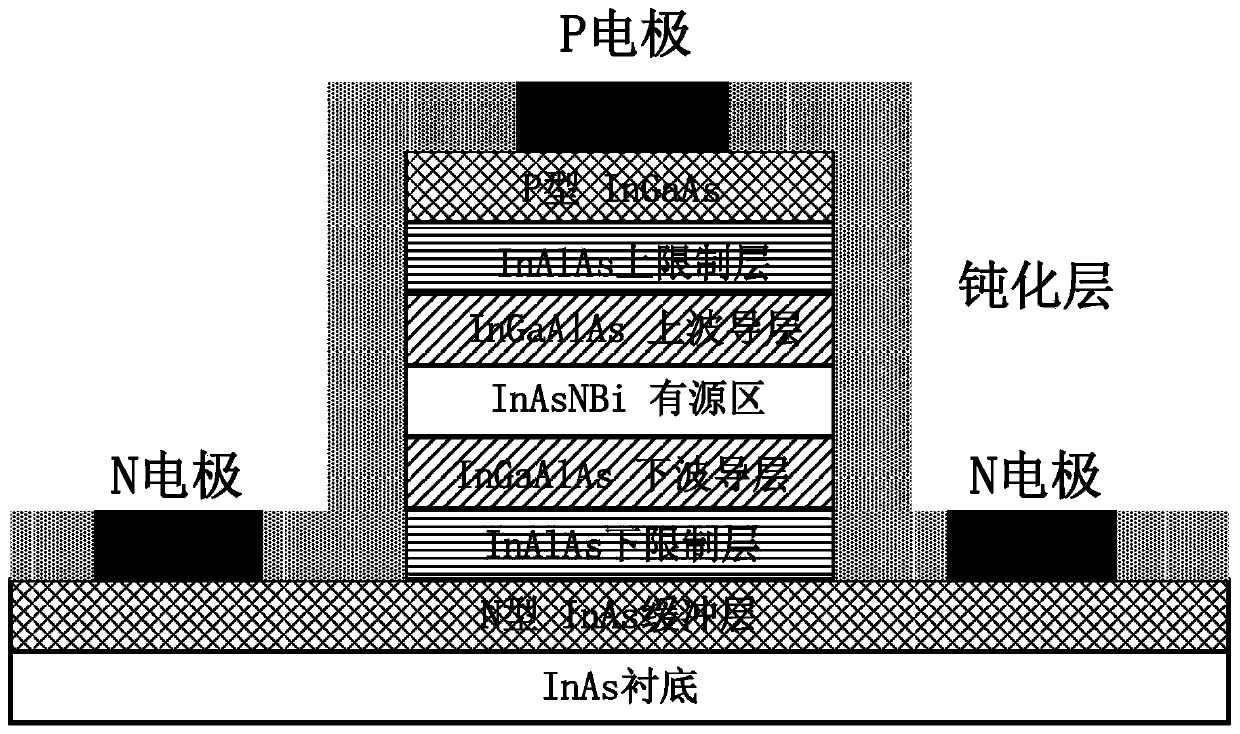

[0065] Example 1: InAsNBi mid-infrared laser

[0066] image 3 is provided according to an embodiment of the present application containing InAs 1-x-y N x Bi y Schematic diagram of the structure of a mid-infrared laser.

[0067] In this embodiment, an InAs buffer layer is epitaxially grown on an InAs substrate or an auxiliary substrate (template) using molecular beam epitaxy (MBE) or metal organic vapor deposition (MOCVD) epitaxial growth tools;

[0068] Epitaxial growth of InAs on the InAs buffer layer 1-x-y N x Bi y Thin films and heterojunction materials.

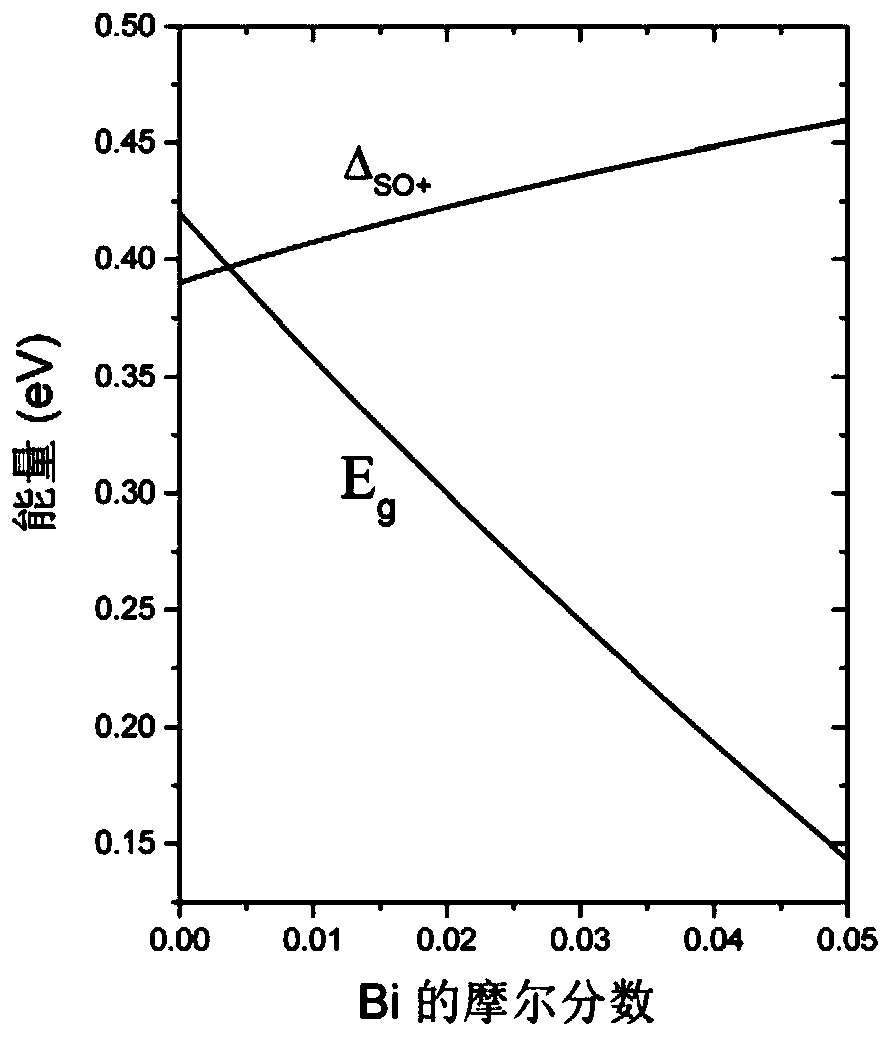

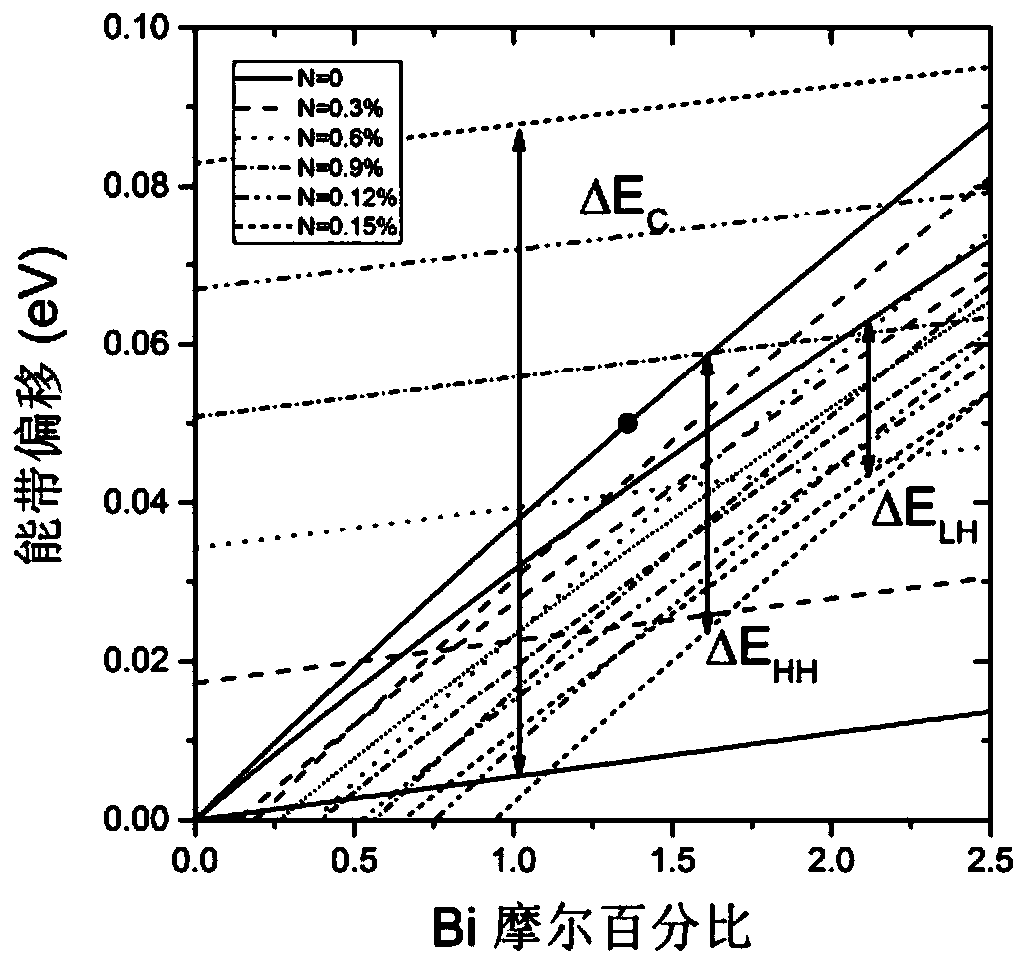

[0069] By controlling the concentration of doped In atoms and Bi atoms, the InAs 1-x-y N x Bi y The band gap of the material, the wavelength range can cover the mid-infrared.

[0070] The laser is a mid-infrared laser, which includes, in order from bottom to top: InAs substrate layer, N-type InAs buffer layer, InAlAs lower confinement layer, InGaAlAs lower waveguide layer, InAs 1-x-y N x Bi y Quantum well a...

Embodiment 2

[0089] Example 2: n-b-i-b-p type InAsNBi mid-infrared detector

[0090] The detector is a mid-infrared detector, which includes in order from bottom to top: InAs substrate, N-type InAs contact layer, N-type InAsNBi hole blocking layer, P-type InAs 1-x-y N x Bi y Absorbing layer, P-type InAsNBi electron blocking layer and P-type InAs contact layer,

[0091] Wherein, the outer surface of the N-type InAs contact layer, the N-type InAsNBi hole blocking layer, the P-type InAsNBi absorbing layer, the P-type InAsNBi electron blocking layer, and the P-type InAs contact layer A passivation layer is deposited,

[0092] An N electrode is photoetched on the N-type InAs contact layer, and a P electrode is photoetched on the P-type InAs contact layer.

[0093] like Figure 4 As shown, the sphalerite-structured InAs 1-x-y N x Bi y The material has a forbidden band width of 0.22eV when N atoms are 4% and Bi atoms are 9.7%, and the corresponding wavelength is 5.64μm, which is located i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com