A kind of visible light alkali generator and preparation method thereof

An alkali generator and visible light technology, applied in the chemical industry, can solve the problems of increasing the degree of conjugation, enhancing the alkalinity, increasing the long-wavelength absorption range of the photosensitizer, etc., and achieving the increase of the degree of conjugation, strong alkalinity, and simple synthesis method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

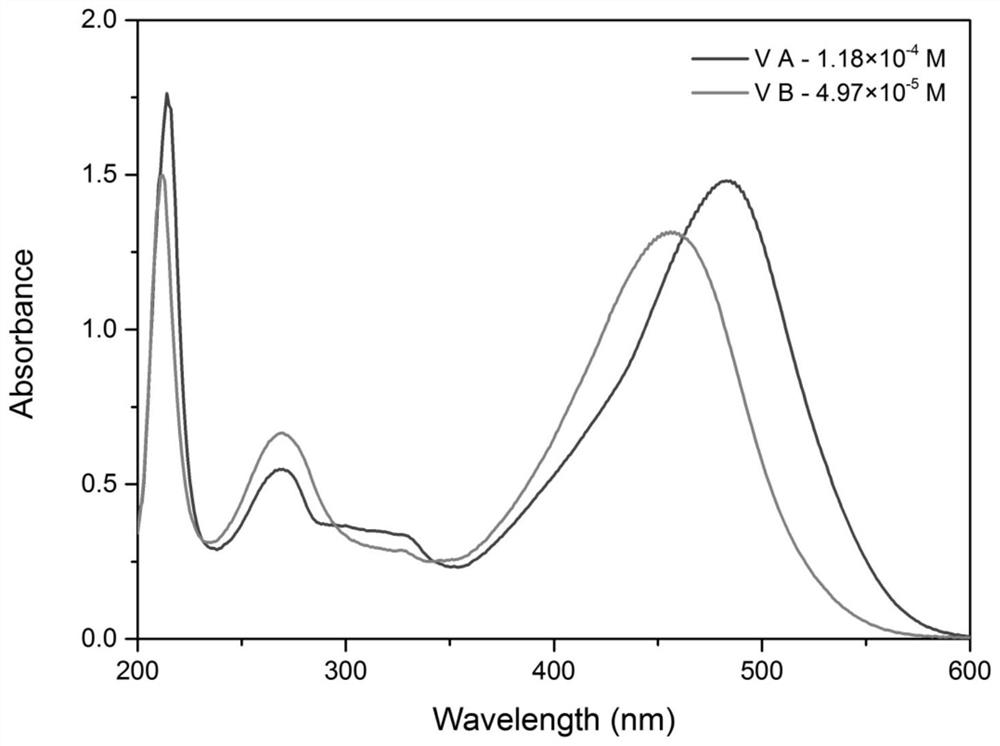

[0050]Add 30mL of ethanol to a 100mL one-necked flask, stir and add 1.04g of N-(4-formylphenyl)-N-methylglycine methyl ester, after fully dissolved, add 0.20g of cyclopentanone and 1.02g of sodium hydroxide , heated to 50°C for 18h. The reaction solution was slowly added dropwise with hydrochloric acid to precipitate a red-black precipitate, which was then filtered and dried by column chromatography. The eluent was a 20:1 mixed solvent of dichloromethane-methanol to obtain 0.40 g of the product with a yield of 36.8%. Disperse 0.24g of the product in 10mL of methanol, dropwise add 0.12g of TBD methanol solution, react in a 50mL single-necked flask at 30°C for 1h, evaporate the methanol under reduced pressure, and obtain 0.34g of visible light base generator (yield: 94.4%). The ultraviolet-visible light absorption spectrum of gained base generator is as figure 1 (Denoted by V A).

[0051] 1 H NMR (400MHz, Chloroform-d) δ7.51(d, J=8.6Hz, 6H), 6.76(d, J=8.9Hz, 4H), 3.97(s, 4H),...

Embodiment 2

[0055] Add 30mL of methanol into a 100mL single-necked flask, stir and add 1.03g of N-(4-formylphenyl)-N-methylglycine methyl ester, after fully dissolving, add 0.24g of 4-methylcyclohexanone and 1.11 g potassium hydroxide, heated to 40 ° C for 24 hours. The reaction solution was slowly added dropwise with sulfuric acid to precipitate a black precipitate, which was filtered and dried by column chromatography, and the eluent was a 20:1 mixed solvent of dichloromethane-methanol to obtain 0.29 g of the product with a yield of 28.6%. Disperse 0.29g of the product in 10mL of methanol, dropwise add 0.14g of TBD methanol solution, react in a 50mL single-necked flask at 20°C for 12h, evaporate the methanol under reduced pressure, and obtain 0.41g of visible light base generator (95.3% yield). The ultraviolet-visible light absorption spectrum of gained base generator is as figure 1 (Denoted by VB).

[0056] 1 H NMR (400MHz, Chloroform-d) δ7.74(s, 2H), 7.41(d, J=8.8Hz, 4H), 6.73(d, J...

Embodiment 3

[0060] Add 30mL of ethanol to a 100mL single-necked flask, stir and add 1.6g of N-(4-formylphenyl)-N-methylglycine methyl ester, after fully dissolved, add 0.3g of cyclopentanone and 0.86g of potassium hydroxide , warming up to 60°C for 4h. The reaction solution was slowly added dropwise with nitric acid to precipitate a red-black precipitate, which was then filtered and dried by column chromatography. The eluent was a 20:1 mixed solvent of dichloromethane-methanol to obtain 0.35 g of the product with a yield of 21.6%. Disperse 0.3g of the product in 10mL N,N-dimethylformamide, add dropwise DBU methanol solution containing 0.15g, react in a 50mL single-necked flask at 60°C for 5h, evaporate N,N-dimethylformamide under reduced pressure , to obtain 0.42g visible light base generator (yield 93.3%).

[0061] 1 H NMR (400MHz, Chloroform-d) δ7.50(d, J=8.6Hz, 6H), 6.79(d, J=8.9Hz, 4H), 4.01(s, 4H), 3.57-3.31(m, 6H) ,3.23(q,J=5.6Hz,20H),2.73(d,J=2.2Hz,3H),1.92-1.79(m,2H),1.45-1.72(...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com