Chemical plugging rubber plug, preparation method and application thereof

A chemical and rubber plug technology, applied in the field of oil and gas field exploration and development, can solve the problems of low viscosity of blasthole plugging fluid, limited use range, poor expansion performance and elastic toughness, etc., and achieve excellent corrosion resistance, irreversible plugging, flow good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

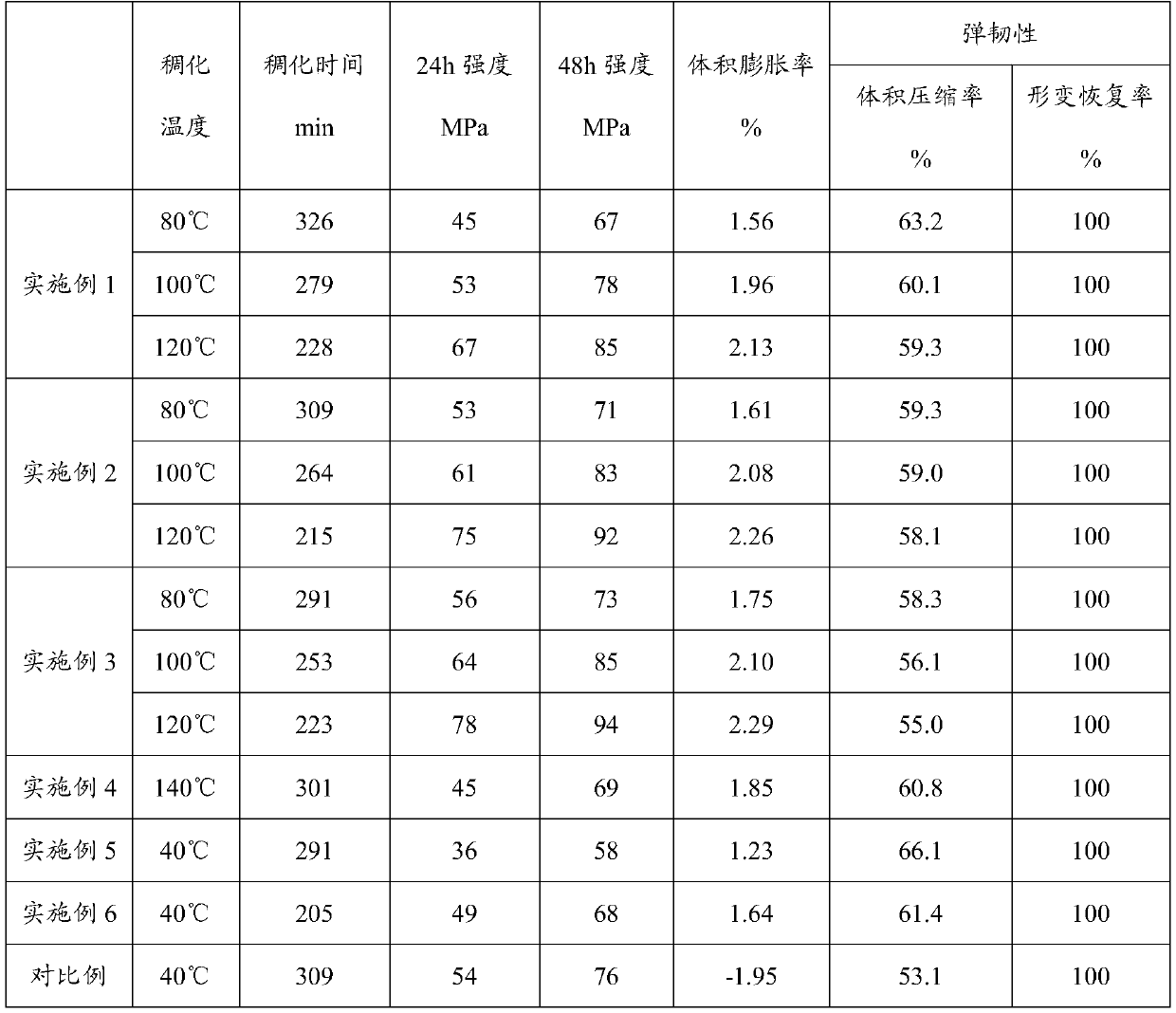

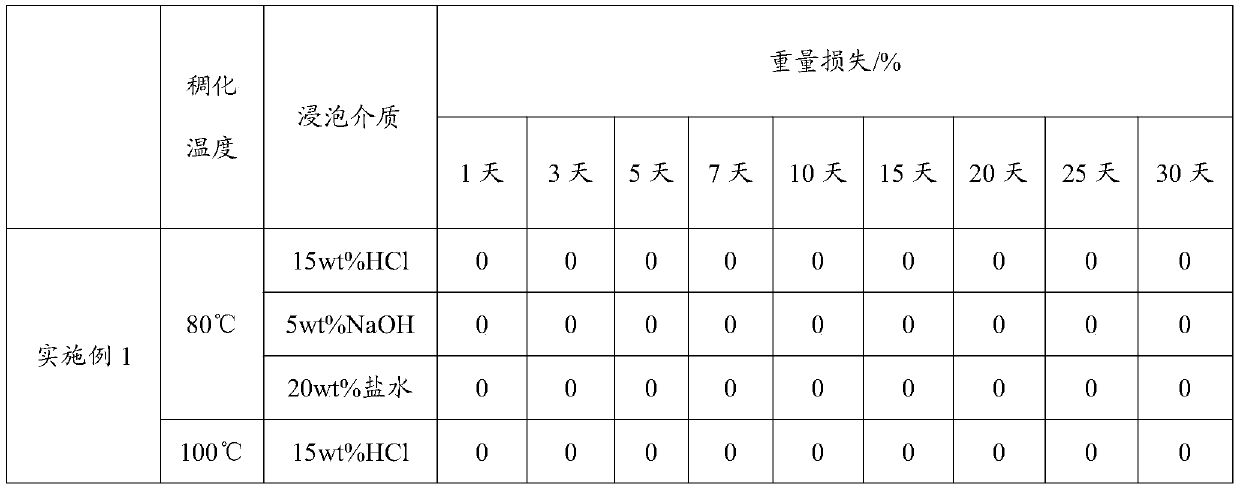

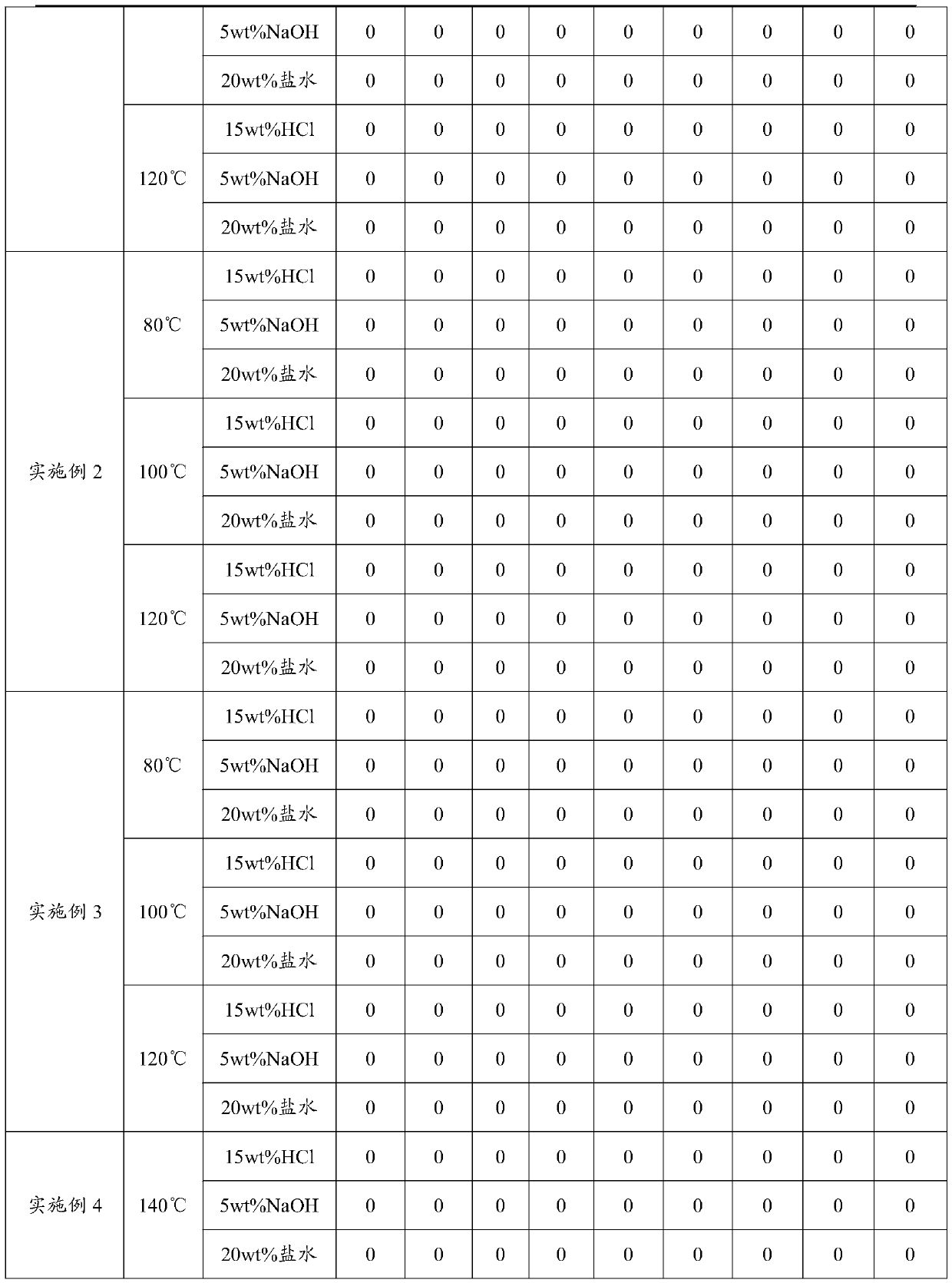

Examples

preparation example Construction

[0032] The present invention provides a method for preparing the chemical plugging rubber plug described in the above technical solution, comprising the following steps: mixing various preparation raw materials for the chemical plugging rubber plug to obtain the chemical plugging rubber plug. In the present invention, the mixing is preferably carried out under stirring conditions, and the stirring speed is preferably 500 r / min.

[0033] In the present invention, when no accelerator is included in the preparation raw materials of the chemical plugging plug, it is preferable to sequentially add a flow regulator, a liquid phase expansion agent, a thickener and a solid phase expansion agent into the resin base liquid Mix to obtain a chemical plugging rubber stopper. In the present invention, the stirring time after mixing the resin base liquid with the flow regulator is preferably 30-60 minutes; the stirring time after mixing with the liquid phase expansion agent is preferably 5 m...

Embodiment 1

[0039] (1) In parts by weight, 40 parts of flow regulators are added to 60 parts of resin base liquid, and stirred for 40 min at a speed of 500 r / min; the resin base liquid consists of 55 parts of epoxy resin and 5 parts of hydantoin Epoxy resin composition; The flow regulator is 1,4-butanediol diglycidyl ether;

[0040] (2) Add 1.8 parts of liquid-phase expansion agent and stir for 5min at a speed of 500r / min; the preparation method of the liquid-phase expansion agent is to add sodium hydroxide to water, add monobutyl ether after fully dissolving, and the water , the mass ratio of monobutyl ether and sodium hydroxide is 100:50:5;

[0041] (3) Add 16 parts of thickening agent and stir for 5 minutes at a speed of 500r / min; the thickening agent is dihydroxyethylethylenediamine;

[0042] (4) Add 0.1 part of accelerator and stir for 5min at a speed of 500r / min; the model of the accelerator is DMP-30;

[0043] (5) Add 0.2 part of solid-phase expansion agent and stir for 5 minutes...

Embodiment 2

[0045] (1) In parts by weight, 40 parts of flow regulators are added to 60 parts of resin base liquid, and stirred for 40 min at a speed of 500 r / min; the resin base liquid consists of 55 parts of epoxy resin and 5 parts of hydantoin Epoxy resin composition; The flow regulator is 1,4-butanediol diglycidyl ether;

[0046] (2) Add 1.8 parts of liquid-phase expansion agent and stir for 5min at a speed of 500r / min; the preparation method of the liquid-phase expansion agent is to add sodium hydroxide to water, add monobutyl ether after fully dissolving, and the water , the mass ratio of monobutyl ether and sodium hydroxide is 100:50:5;

[0047] (3) Add 18 parts of thickening agent and stir for 5 minutes at a speed of 500r / min; the thickening agent is dihydroxyethylethylenediamine;

[0048] (4) Add 0.1 part of accelerator and stir for 5min at a speed of 500r / min; the model of the accelerator is DMP-30;

[0049] (5) Add 0.2 part of solid-phase expansion agent and stir for 5 minutes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com