Pollution prevention microcapsules and preparation method and application thereof

A microcapsule and antifouling technology, which is applied in the direction of microcapsule preparation, microsphere preparation, antifouling/underwater coating, etc., can solve the complex process, antifouling microcapsule coating rate and antifouling performance need to be improved, reagents A wide range of drugs and other problems, to achieve the effect of excellent hydrophobic performance and antifouling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

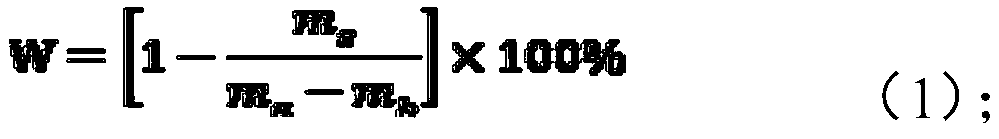

Method used

Image

Examples

preparation example Construction

[0048] The present invention also provides a method for preparing the above-mentioned antifouling microcapsules, comprising the following steps:

[0049] Reacting the coagulation bath and the mixed solution at room temperature to obtain antifouling microcapsules;

[0050] The coagulation bath includes an isocyanate solution;

[0051] The mixed solution includes resin solution containing hydroxyl group, water-absorbing resin, silicone oil and antifouling agent.

[0052] The raw materials used in the preparation of antifouling microcapsules in the present invention are coagulation bath and mixed solution.

[0053]In the present invention, the coagulation bath includes an isocyanate solution. In an embodiment of the present invention, the isocyanates in the isocyanate solution include toluene diisocyanate, isophorone diisocyanate, diphenylmethane diisocyanate, dicyclohexylmethane diisocyanate, hexamethylene diisocyanate and lysine One or more of acidic diisocyanates. The solv...

Embodiment 1

[0109] Weigh 6.2g of polyvinyl alcohol resin into 120g of ethyl acetate, stir and mix at 70°C for 40min to obtain a resin solution containing hydroxyl groups; then weigh 2.5g of simethicone, 3.0g of DCOIT and 5.0g of grafted propylene Add the amide to the resin solution containing hydroxyl groups, use a nano-sand mill at room temperature, and stir at 2000r / min at a high speed for 180min to obtain a mixed solution with a particle size of 1 μm; at the same time, mix 6g of toluene diisocyanate and 50g of ethyl acetate to obtain Coagulation bath (concentration of isocyanate solution is 10.7wt%); the mixed solution is added dropwise into the coagulation bath, reacted at room temperature for 35 minutes, suction filtered and dried to obtain antifouling microcapsules.

[0110] Mix antifouling microcapsules, epoxy polysiloxane resin, yellow-green energy storage fluorescent powder and toluene to prepare a bionic antifouling coating. In the bionic antifouling coating, the content of antif...

Embodiment 2

[0113] Weigh 5.6g of phenolic resin and add it to 100g of dimethyl sulfoxide, stir and react at 75°C for 35min to obtain a resin solution containing hydroxyl groups; then weigh 2.8g of hydroxyl silicone oil, 2.8g of tannic acid and 5.2g of high degree of substitution Add cross-linked carboxymethyl cellulose to the resin solution containing hydroxyl groups, use a nano sand mill at room temperature, and stir at a high speed of 2000r / min for 150min to obtain a mixed solution with a particle size of 1.5μm; at the same time, add 5g of isophorone Diisocyanate and 50g dimethyl sulfoxide are mixed to obtain a coagulation bath (the concentration of the isocyanate solution is 9.1wt%); the mixed liquid is added dropwise in the coagulation bath, reacted at room temperature for 26min, and after suction filtration and drying, the obtained Anti-fouling microcapsules.

[0114] Mix antifouling microcapsules, fluorine-modified polyester resin, rare earth long-lasting fluorescent powder and xyle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com