Self-cleaning circulating water paint capable of capturing haze

A circulating water, self-cleaning technology, applied in the field of water paint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

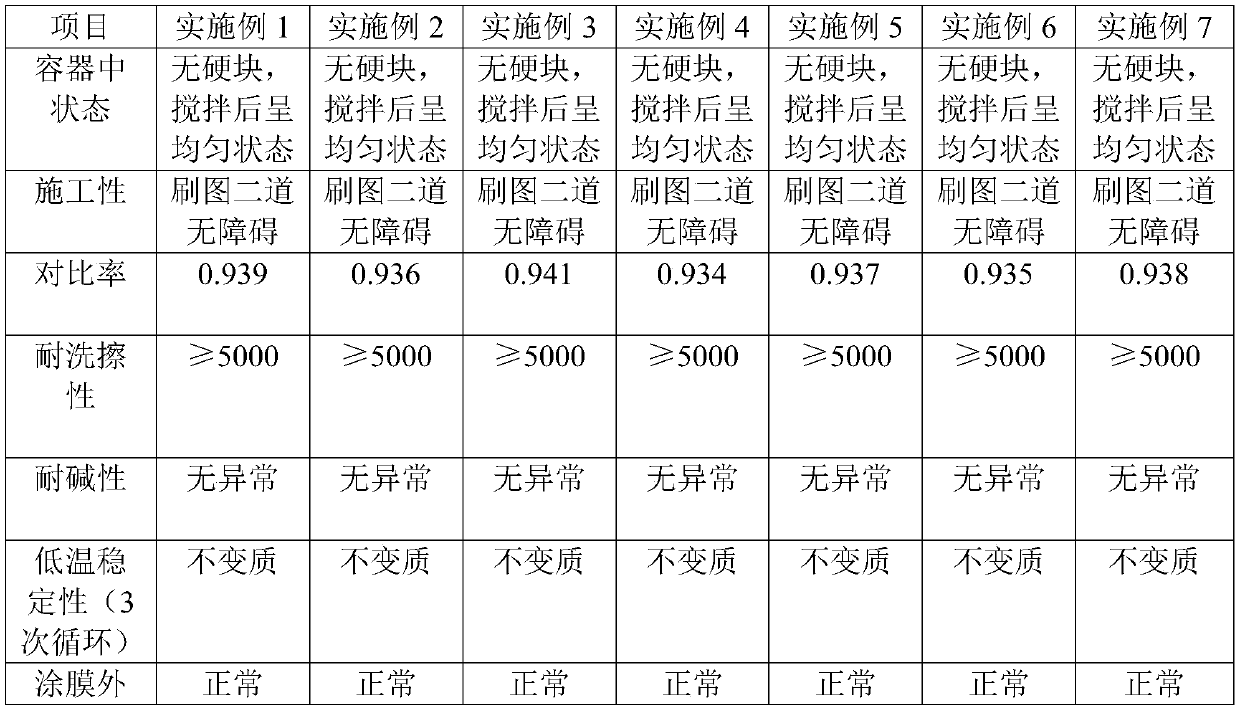

Examples

Embodiment 1

[0025] Polyacrylic acid emulsion: in parts by weight, including 110 parts of water, 55 parts of styrene, 45 parts of methyl methacrylate, 18 parts of isooctyl acrylate, 32 parts of butyl acrylate, 1 part of acrylic acid, and 2 parts of methacrylic acid , 1 part of acrylamide, 3 parts of methacrylamide, 10 parts of sodium dodecylbenzenesulfonate, 2 parts of ethylene glycol dimethacrylate, 0.2 parts of ammonium persulfate, 0.1 part of hydrogen peroxide, and 0.3 parts of sodium sulfite .

[0026] Described polyacrylic acid emulsion is prepared by following method, comprises the following steps:

[0027] (1) Preparation: prepare raw materials according to the above parts by weight, and set aside;

[0028] (2) Pre-emulsification: under normal temperature and pressure, mix 3 parts of sodium dodecylbenzenesulfonate and 20 parts of water, stir and dissolve, then add acrylic acid, methacrylic acid, acrylamide, methacrylamide, phenylethyl ether Dilute, butyl acrylate, isooctyl acrylat...

Embodiment 2

[0037] Polyacrylic acid emulsion: in parts by weight, including 120 parts of water, 60 parts of styrene, 55 parts of methyl methacrylate, 19 parts of isooctyl acrylate, 40 parts of butyl acrylate, 2 parts of acrylic acid, and 3 parts of methacrylic acid , 3 parts of acrylamide, 1 part of methacrylamide, 18 parts of sodium lauryl sulfate, 3 parts of alkenyltrimethoxysilane, 0.5 parts of potassium persulfate, 0.2 parts of hydrogen peroxide, and 0.4 parts of sodium bisulfite.

[0038] Described polyacrylic acid emulsion is prepared by following method, comprises the following steps:

[0039] (1) Preparation: prepare raw materials according to the above parts by weight, and set aside;

[0040] (2) Pre-emulsification: under normal temperature and pressure, mix 5 parts of sodium lauryl sulfate and 30 parts of water, stir and dissolve, then add acrylic acid, methacrylic acid, acrylamide, methacrylamide, styrene, Butyl acrylate, isooctyl acrylate, methyl methacrylate, and stirred for 3...

Embodiment 3

[0049] Polyacrylic acid emulsion: in parts by weight, including 130 parts of water, 65 parts of styrene, 50 parts of methyl methacrylate, 20 parts of isooctyl acrylate, 50 parts of butyl acrylate, 3 parts of acrylic acid, and 4 parts of methacrylic acid , 2 parts of acrylamide, 2 parts of methacrylamide, 15 parts of alkylphenol ethoxylate ammonium sulfate, 4 parts of alkenyltrimethoxysilane, 0.9 parts of potassium persulfate, 0.3 parts of hydrogen peroxide, sodium thiosulfate 0.5 servings.

[0050] Described polyacrylic acid emulsion is prepared by following method, comprises the following steps:

[0051] (1) Preparation: prepare raw materials according to the above parts by weight, and set aside;

[0052] (2) Pre-emulsification: under normal temperature and pressure, mix 7 parts of alkylphenol ethoxylate ammonium sulfate and 40 parts of water, stir and dissolve, then add acrylic acid, methacrylic acid, acrylamide, methacrylamide, benzene Ethylene, butyl acrylate, isooctyl a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com