Amoxicillin and clavulanate potassium preparations and preparation method thereof

A technology of amoxicillin-clavulanate potassium and clavulanate potassium, which is applied in the direction of pill delivery, pharmaceutical formulations, medical preparations of non-active ingredients, etc., can solve the problem of reducing drug efficacy, reducing the content of amoxicillin active ingredients, shortening the Process and other issues, to achieve rapid effect, high bioavailability, fast absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

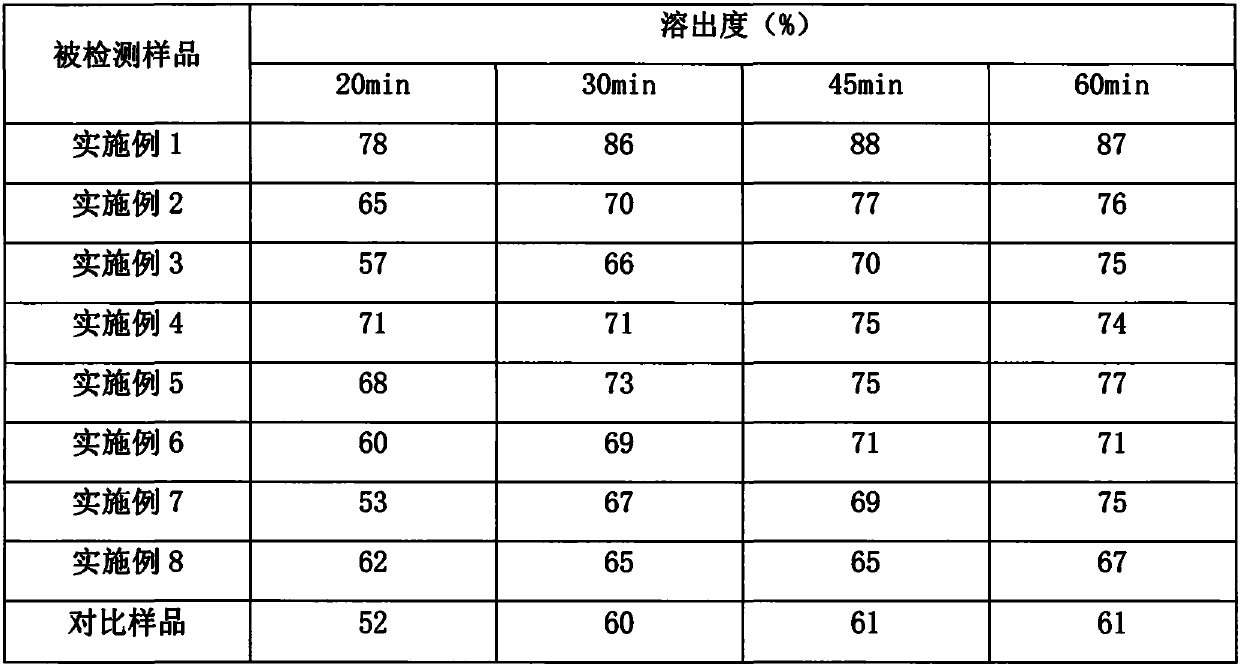

Examples

Embodiment 1

[0041] Embodiment 1 (preparation of dropping pill) (best)

[0042] Prepare according to the preparation method of the dropping pill in the above-mentioned preparation method, take polyethylene glycol 4000 468.75g and put it in the chemical material tank, turn on the heating system of the chemical material tank, adjust the temperature to 55 ° C, after the polyethylene glycol is completely melted, Open the stirring paddle of the chemical material tank, slowly add potassium clavulanate 31.25g and amoxicillin 125g, when the medicinal liquid becomes a molten liquid state, adjust the temperature control system of the dropping pill machine so that the temperature of the dripper of the dropping pill machine is heated and Keep it at 55°C, cool the temperature of the condensing agent and keep it at 3°C, put the medicine liquid in the dripping tank of the dropping pill machine, drop it into the simethicone oil through the dripper, and drop the shrinkage formed drops from the outlet of the...

Embodiment 2

[0044]Prepare according to the preparation method of the dripping pill in the above preparation method, take polyethylene glycol 6000 650g and put it in the chemical material tank, turn on the heating system of the chemical material tank, adjust the temperature to 75 ° C, after the polyethylene glycol is completely melted, turn on the Slowly add 30g of potassium clavulanate and 100g of amoxicillin to the stirring paddle of the chemical material tank. When the medicine liquid becomes a molten liquid state, adjust the temperature control system of the dropping pill machine so that the temperature of the dripper of the dropping pill machine is heated and kept at 75°C, the temperature of the condensing agent is cooled and kept at -1°C, the liquid medicine is placed in the dropping tank of the dropping pill machine, dripped into the simethicone oil through the dripper, and the shrinkage-shaped dropping pills are discharged from the outlet of the dropping pill machine Take it out, re...

Embodiment 3

[0046] Prepare according to the preparation method of the dripping pill in the above preparation method, take 10000765g of polyethylene glycol and put it in the chemical tank, turn on the heating system of the chemical tank, adjust the temperature to 75°C, and turn on the chemical tank after the polyethylene glycol is completely melted. Slowly add 33g of potassium clavulanate and 120g of amoxicillin to the stirring paddle of the material tank. When the liquid medicine is in a molten state, adjust the temperature control system of the dropping pill machine so that the dripper temperature of the dropping pill machine is heated and kept at 65 ℃, the temperature of the condensing agent is cooled and kept at 0 ℃, the liquid medicine is placed in the dripping tank of the dropping pill machine, dripped into the simethicone oil through the dripper, and the shrinkage-shaped dropping pills are taken out from the outlet of the dropping pill machine. Remove the surface condensing agent, dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com