Sulfur-containing flue gas biochemical desulfurizing and sulfur recycling method

A sulfur recovery and flue gas technology, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of circulation path, process efficiency reduction, disadvantages and other problems that have not been mentioned in the biochemical treatment of effluent, and achieve material cost and operation Low cost, significant environmental benefits, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

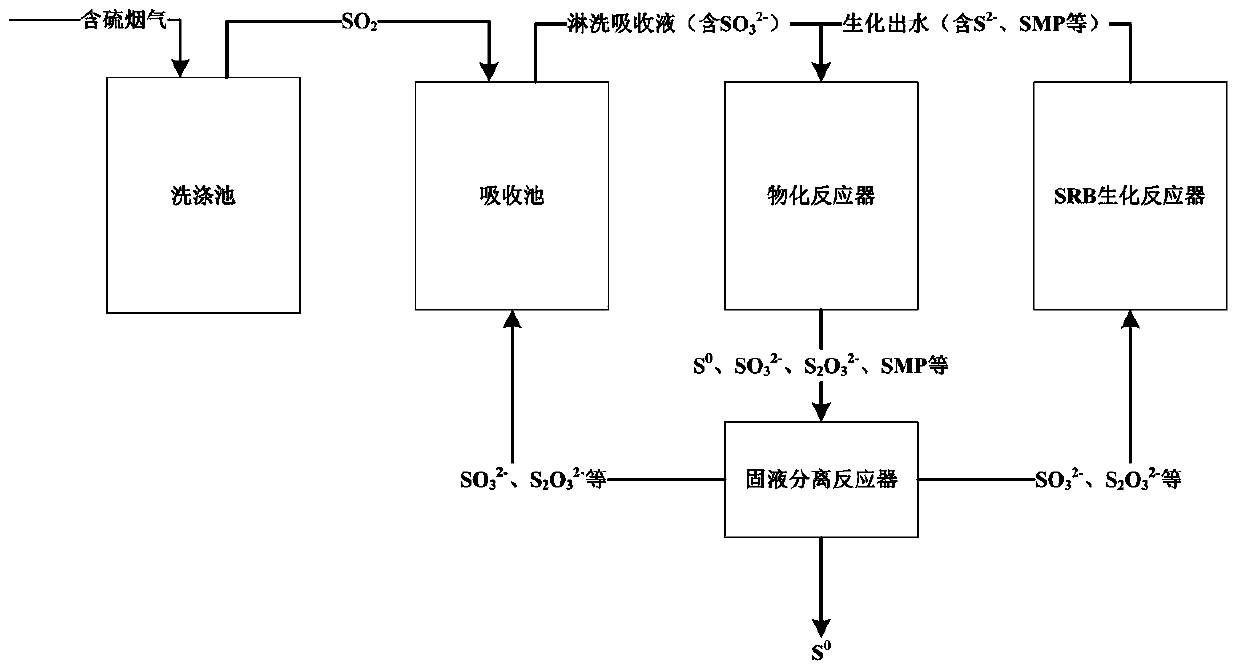

Method used

Image

Examples

Embodiment 1

[0042] Sulfur-containing flue gas produced by burning coal in a thermal power plant. Utilize the method of the present invention, the liquid-gas ratio of water leaching in the washing tank is 1, and the liquid-gas ratio of water rinsing in the absorption tank is 10, and the pH of sulfurous acid absorption liquid is 1~2.5 in the treatment process, and redox potential is 130~300mV; SRB biochemical treatment effluent pH is 5~6, redox potential is -400~-250mV; sulfur production conditions are controlled at pH 1~4, redox potential is -100~250mV, SO 3 2- / S 2- The molar ratio is 6:1 ~ 3:1; the method of sulfur separation adopts the air flotation method; the microorganisms used in the SRB biochemical reactor are 70% Desulfurization Enterobacter ( Desulfotomaculum ), 30% of Desulfomonas ( Desulfomonus ) composed of mixed flora. Under these conditions, the yield of sulfur was 42%, and the recovery rate of sulfur after air flotation separation was 85%.

Embodiment 2

[0044] Sulfur-containing flue gas produced by burning coal in a thermal power plant. Utilize the method of the present invention, the liquid-gas ratio of water leaching in the washing tank is 1, and the liquid-gas ratio of water rinsing in the absorption tank is 10, and the pH of sulfurous acid absorption liquid is 1~2.5 in the treatment process, and redox potential is 130~300mV; SRB biochemical treatment effluent pH is 5~6, redox potential is -400~-250mV; sulfur production conditions are controlled at pH 1~4, redox potential is -100~250mV, SO 3 2- / S 2- The molar ratio is 6:1 ~ 3:1; the method of sulfur separation adopts the air flotation method; the microorganisms used in the SRB biochemical reactor are 30% Desulfurization Enterobacter ( Desulfotomaculum ), 70% of Desulfomonas ( Desulfomonus ) composed of mixed flora. Under this condition, the yield of sulfur is 40%, and the recovery rate of sulfur after air flotation separation is 85%.

Embodiment 3

[0046] Sulfur-containing flue gas from a steel plant. Utilize the method of the present invention, the liquid-gas ratio of water leaching in the washing tank is 3, and the liquid-gas ratio of water rinsing in the absorption tank is 13, and the pH of sulfurous acid absorption liquid is 2~4 in the treatment process, and redox potential is 100~200mV; SRB biochemical treatment effluent pH is 6~7, redox potential is -300~-100mV; sulfur production conditions are controlled at pH 2~6, redox potential is -200~150mV, SO 3 2- / S 2- The molar ratio is 3:1~1:1; the method of sulfur separation adopts centrifugation; the microorganisms used in the SRB biochemical reactor are 20% Desulfovibrio ( Desulfovibrio ), 10% of Desulfoenterobacteriaceae ( Desulfotomaculum ), 50% of Desulfomonas ( Desulfomonus ), 10% of Desulfolobus ( Desulfobulbus ) composed of mixed flora. Under this condition, the yield of sulfur is 50%, and the recovery rate of sulfur after centrifugation is 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com