High-performance polycarboxylic acid water reducing agent and preparation method thereof

A high-performance, polycarboxylic acid technology, used in the field of concrete admixtures in the construction industry, can solve the problems of poor adaptability of water reducer and concrete, large water absorption of modified mineral powder, large adsorption capacity of water reducer, etc. Excellent performance, high reinforced strength growth rate, good slump retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

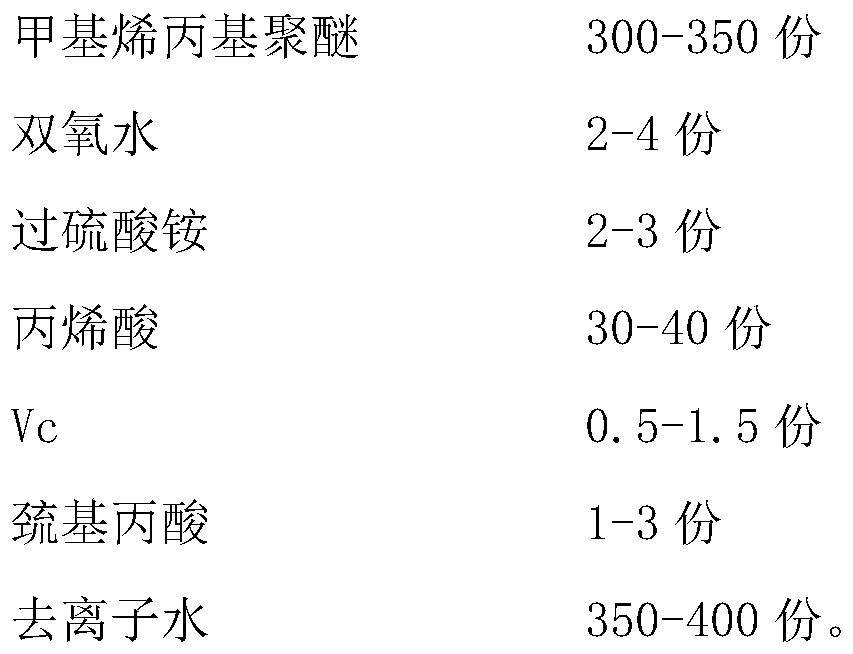

[0040] Raw material selection:

[0041] 1. Polymerized monomer: acrylic acid, methallyl polyoxyethylene ether (TPEG) monomer;

[0042] 2. Polymerization initiator: persulfate, hydrogen peroxide;

[0043] 3. Molecular weight regulator: mercaptopropionic acid, Vc;

[0044] Brief description of laboratory synthesis process: add 264 parts of bottom water (weight fraction, the same below) to the reactor, add 300 parts of TPEG at room temperature to dissolve, add 3 parts of hydrogen peroxide, 2.2 parts of ammonium persulfate, and drop acrylic acid And the mixed solution of mercaptopropionic acid and Vc (acrylic acid: Vc: mercaptopropionic acid: water = 33.3: 0.95: 2: 124), slowly and control the rate of addition, drop over one hour, the synthesis process is carried out at room temperature, synthesis Self-exothermic, the temperature at the end of the reaction rises to 30-40°C, and the temperature is kept for one hour. Adjust pH 6-7 as needed. A colorless viscous liquid polycarbox...

Embodiment 2

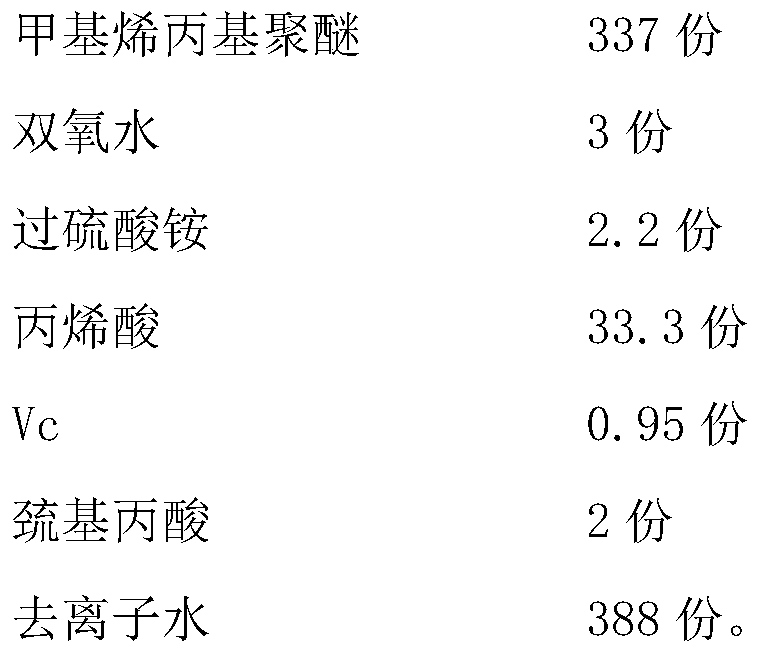

[0046] Add 264 parts of bottom water (weight fraction, the same below) in the reaction kettle, add 337 parts of TPEG to dissolve at room temperature, add 2 parts of hydrogen peroxide, 2 parts of ammonium persulfate after dissolving, add dropwise acrylic acid, mercaptopropionic acid and Vc Mix the solution (acrylic acid: Vc: mercaptopropionic acid: water = 33.3: 0.95: 2: 124), slowly and control the rate of addition, drop over one hour, the synthesis process is carried out at room temperature, the synthesis itself exothermic, the reaction end temperature Rise to 30-40°C and keep warm for one hour. Adjust pH 6-7 as needed. A colorless viscous liquid polycarboxylate high-performance water reducer with a weight average molecular weight of 27980 was obtained.

Embodiment 3

[0048] Add 264 parts of bottom water (weight fraction, the same below) in the reaction kettle, add 350 parts of TPEG to dissolve at room temperature, add 4 parts of hydrogen peroxide, 3 parts of ammonium persulfate after dissolving, add dropwise acrylic acid, mercaptopropionic acid and Vc Mix the solution (acrylic acid: Vc: mercaptopropionic acid: water = 33.3: 0.95: 2: 124), slowly and control the rate of addition, drop over one hour, the synthesis process is carried out at room temperature, the synthesis itself exothermic, the reaction end temperature Rise to 30-40°C and keep warm for one hour. Adjust pH 6-7 as needed. A colorless viscous liquid polycarboxylate high-performance water reducer with a weight average molecular weight of 28530 was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com