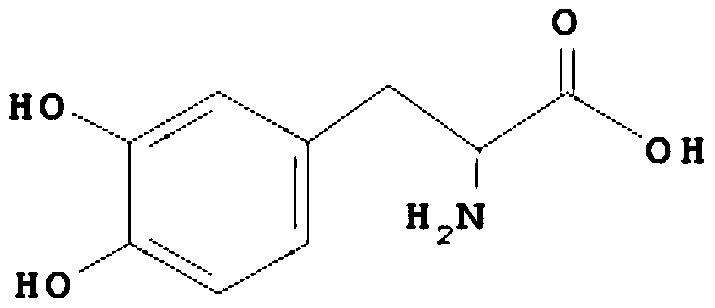

A kind of co-production process and application of pyruvic acid and levodopa

A technology for pyruvic acid and pyruvic acid is applied in the field of fermentation and enzymatic catalysis, which can solve the problems of high conversion rate, high substrate cost, and no industrialized production, and achieve the effects of reducing three wastes and raw material costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0031] Example 1: Obtaining pyruvate by fermentation

[0032] Activation medium (YPD liquid medium): 1% yeast extract, 2% peptone, 2% glucose.

[0033] Seed medium: 10% glucose, 3% fish peptone, 0.1% KH2PO4, 0.05% MgSO4·7H2O, 4 mg / L nicotinic acid, 400 μg / L pyridoxal, 20 μg / L biotin and 4% CaCO3, pH 5.5.

[0034]Fermentation medium: 10% glucose, 0.1% soybean peptone, 0.6% (NH4) 2SO4, 0.1% KH2PO4, 0.05%, MgSO4 7H2O, 8 mg / L niacin, 1 mg / L pyridoxal, 20 μg / L biotin, 20 μg / L Thiamine and 4% CaCO3, pH 5.5.

[0035] Activation culture: Inoculate the strains stored in the -80°C cryopreservation tube into a 30ml screw bottle containing 5ml YPD liquid medium with a pipette tip, and activate the culture at 30°C or 40°C, 220r / min, approx. After 12 hours, the cells were grown to the logarithmic phase for transfer culture.

[0036] Seed culture: inoculate the activated bacterial liquid into a 500ml shake flask with a certain volume (10, 15, 25ml) of seed medium, and cultivate for 24 hou...

example 2

[0040] Example 2: Fermentative production of tyrosine phenol lyase

[0041] LB medium: tryptone 10g / L, yeast extract 0.5g / L, sodium chloride 10g / L, pure water.

[0042] Fermentation medium: tryptone 12g / L, yeast extract 24g / L, glycerin 5g / L, potassium dihydrogen phosphate 2.31g / L, dipotassium hydrogen phosphate trihydrate 16.43g / L, pure water.

[0043] 1) Pick a single colony and inoculate it into a 4ml LB medium test tube, add kanamycin (50mg / L), 37°C, 220rpm, and cultivate for 12h to obtain first-grade seeds;

[0044] 2) The primary seeds were inoculated into 100ml of fermentation medium shake flask, 37°C, 220rpm, cultured for 4h, added IPTG to a final concentration of 1mM, 25°C, 220rpm, cultured for 12h;

[0045] 3) Centrifuge the bacterial liquid in step (2) to collect the bacterial cells, and place in a -20°C refrigerator.

example 3

[0046] Example 3: Extraction of Tyrosine Phenol Lyase

[0047] 1) Add 3 times the volume of water to the bacteria, and break the cells with a high-pressure homogenizer;

[0048] 2) High-speed centrifugation to obtain supernatant enzyme liquid;

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com