A kind of positive electrode material of lithium ion battery and preparation method thereof

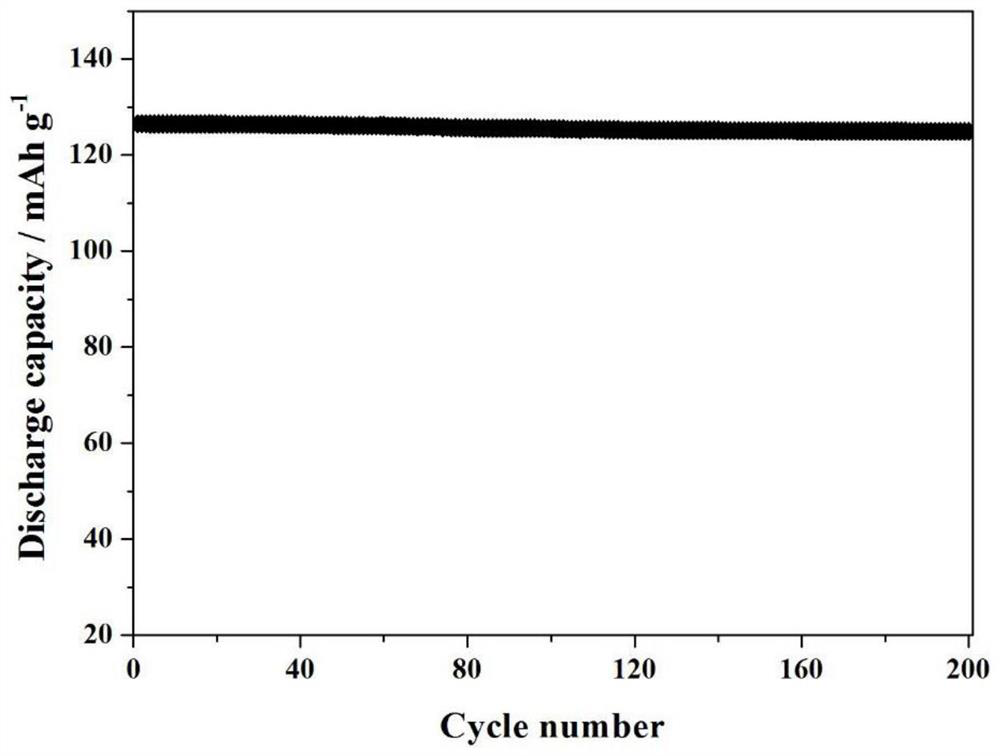

A technology for lithium ion batteries and cathode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of structural stability of lithium ion diffusion, restricting large-scale commercial applications, poor cycle stability, etc., and achieve excellent cycle. Stability, excellent high rate performance, the effect of improving electronic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

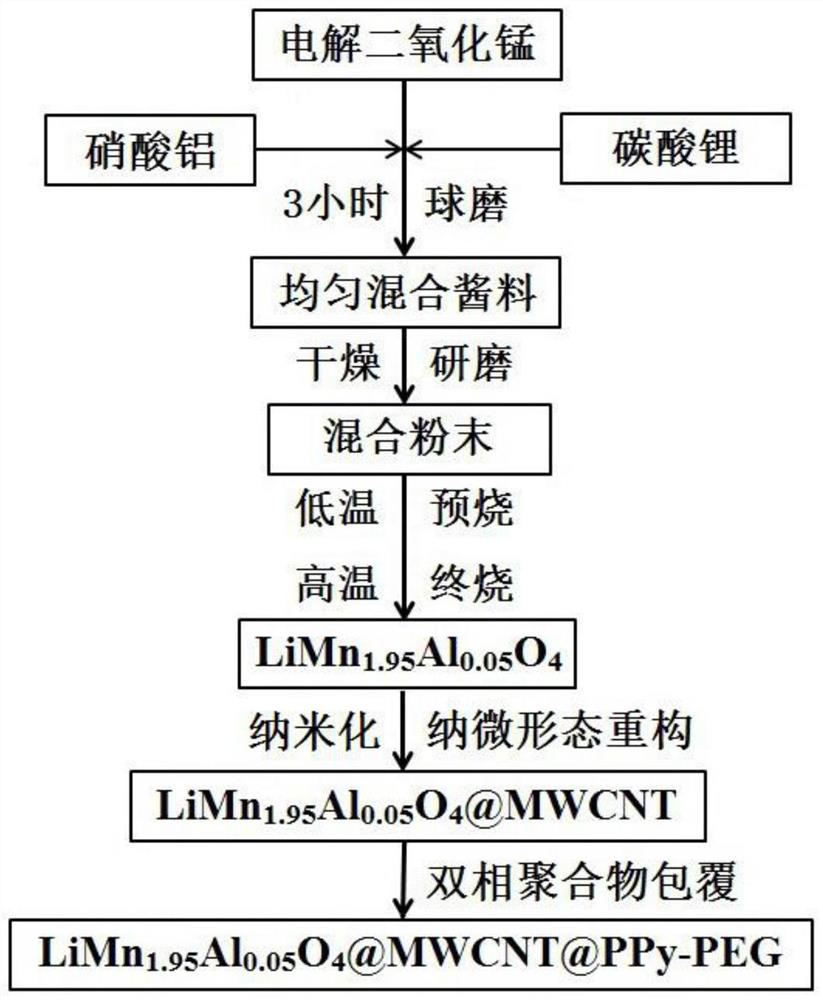

[0034] The present invention also provides a preparation method for the above-mentioned lithium-ion battery cathode material, comprising the following steps:

[0035] (1) Mix Li source, Mn source and dopant according to stoichiometric ratio to obtain mixed slurry; said dopant includes Mg source, Zn source, Cu source, Ni source, Co source, Cr source, Al source , Ga source, In source, Tl source, Ti source, Si source or Zr source;

[0036] The mixed slurry is sequentially dried, pre-calcined and final-calcined to obtain doped modified lithium manganate;

[0037] (2) refine the doped modified lithium manganate obtained in the step (1), to obtain nanoscale doped modified lithium manganate;

[0038] (3) Granulating after mixing the nano-scale doped modified lithium manganese oxide and carbon nanotubes obtained in the step (2), obtaining a micron-scale spherical core based on carbon nanotube three-dimensional contact consolidation;

[0039] (4) Dispersing the conducting polymer mon...

Embodiment 1

[0054] Embodiment 1 prepares the flow chart of lithium-ion battery cathode material as figure 1 shown, according to figure 1 The method shown prepares the positive electrode material of lithium ion battery.

[0055] Aluminum nitrate, electrolytic manganese dioxide and lithium carbonate were mixed according to the molar ratio of Li, Mn and Al of 1.05:1.95:0.05, and wet ball milled for 3 hours under the action of anhydrous ethanol grinding aid. After ball milling, the obtained mixed slurry was transferred to an evaporating dish for drying. Finally, grind the dried mixture evenly and place it in a muffle furnace for pre-calcination at 450°C for 4h, then grind it again and place it in a muffle furnace for final firing at 800°C for 12h to obtain LiMn 1.95 al 0.05 o 4 .

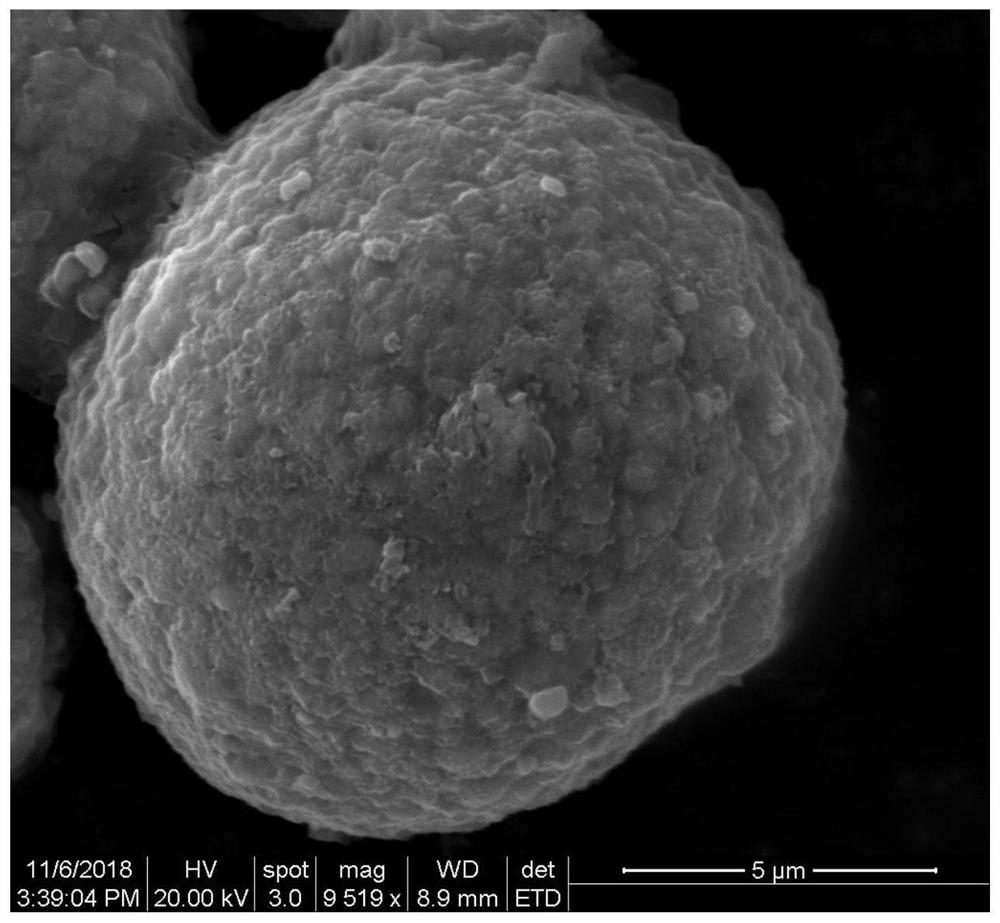

[0056] LiMn prepared by ball milling 1.95 al 0.05 o 4 Grinding into nano-sized particles, the dispersant is absolute ethanol, the rotating speed is 300r / min, and the time is 10h. Then 10 g of the obtained ...

Embodiment 2

[0061] Mix magnesium nitrate, trimanganese tetraoxide and lithium hydroxide according to the molar ratio of Li, Mn and Mg of 1.05:1.95:0.05, and wet ball mill for 3 hours under the action of absolute ethanol grinding aid. After ball milling, the obtained mixed slurry was transferred to an evaporating dish for drying. Finally, the dried mixture was ground evenly and placed in a muffle furnace for pre-calcination at 400°C for 6 hours, and then ground again and placed in a muffle furnace for final firing at 780°C for 15 hours to obtain LiMn 1.95 Mg 0.05 o 4 .

[0062] LiMn prepared by ball milling 1.95 Mg 0.05 o 4 Grinding into nano-sized particles, the dispersant is absolute ethanol, the rotating speed is 300r / min, and the time is 10h. Then 12 g of the obtained nanoparticles and 1 g of MWCNT were mixed, 15 mL of deionized water was added, and the resulting solution was spray-dried at 180 ° C to obtain the core LiMn 1.95 Mg 0.05 o 4 @MWCNT, and dried at 150°C.

[0063] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com