An automatic chip removal device for cutting equipment

A cutting equipment, automatic cleaning technology, applied in the direction of metal processing equipment, manufacturing tools, metal processing machinery parts, etc., can solve the problems of insufficient automaticity and inconvenient cleaning, and achieve the effects of cost saving, prolonging service life and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

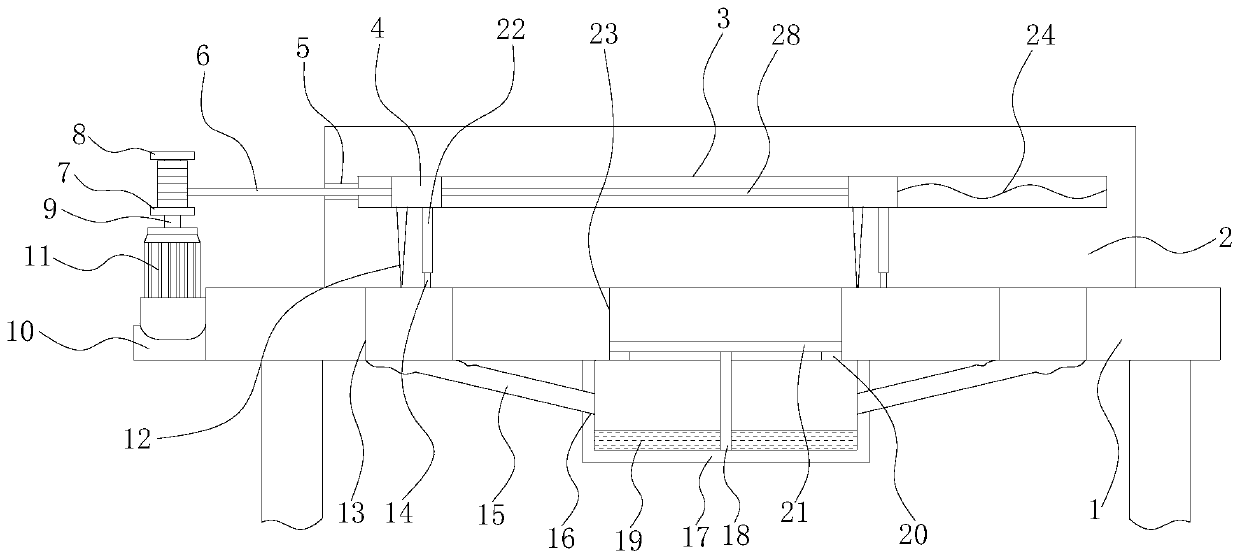

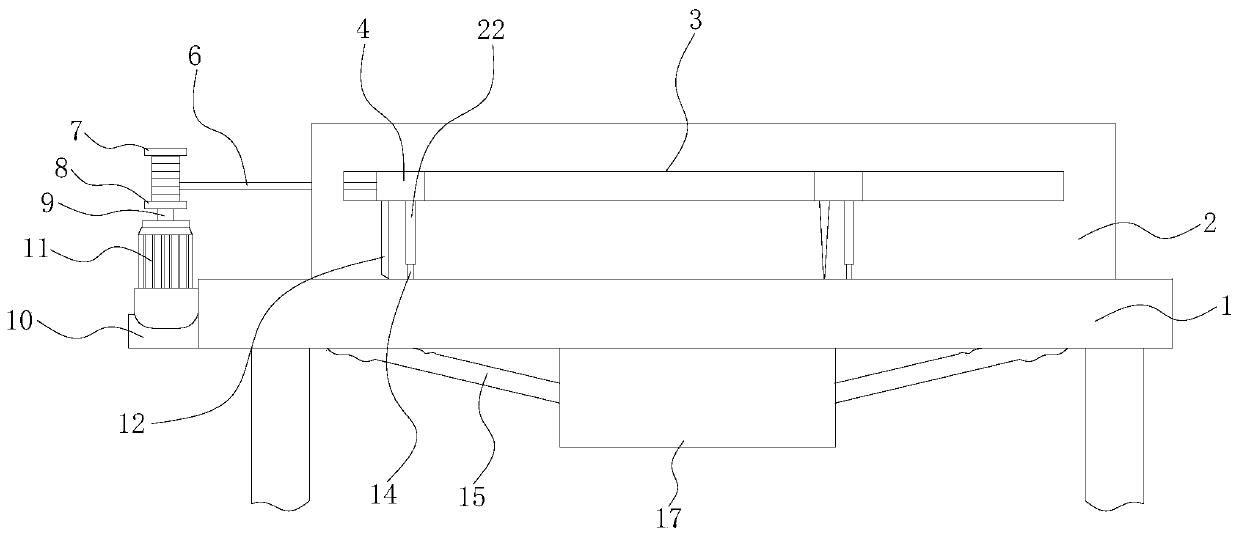

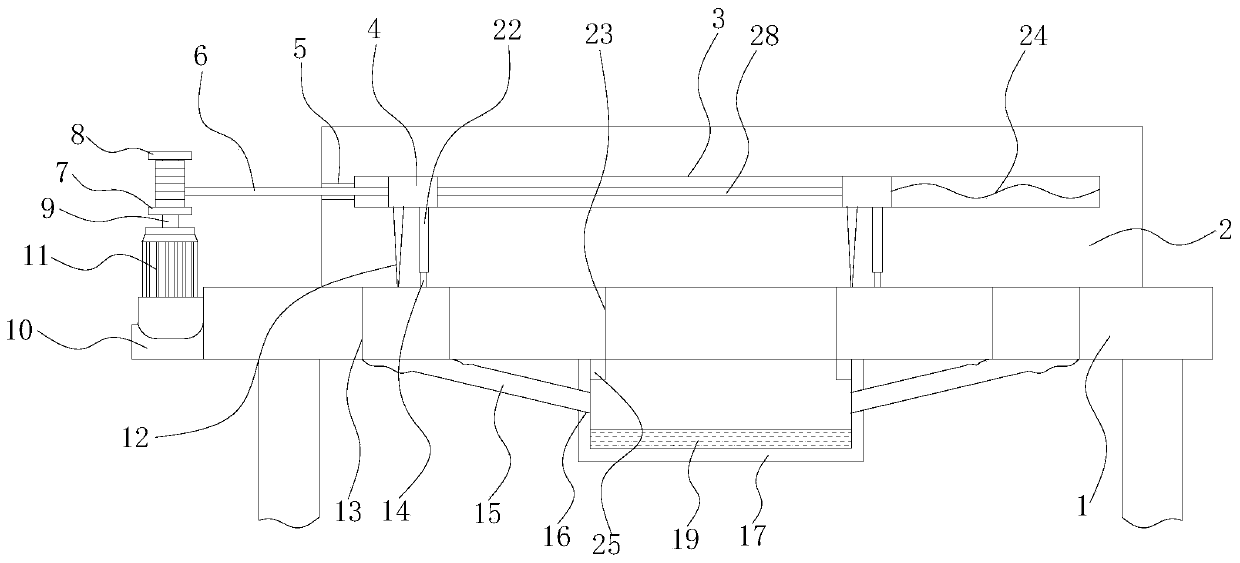

[0038] Such as Figure 1-2As shown, an automatic chip removal device for cutting equipment includes a cutting table 1, and a chip removal hole 13 penetrating the cutting table 1 is opened on the cutting table 1, and auxiliary holes 23 are symmetrically opened on both sides of the chip removal hole 13; the cutting table The upper surface of 1 is fixed with a backplane 2, and the front of the backplane 2 is provided with a moving groove 3 along the length direction of the backplane 2, and two sliding rods 4 are slidably connected in the moving groove 3, and the two sliding rods 4 extend out of the moving groove 3. The lower surface of the back is connected with a scraper 12 and a vertical plate 22 arranged side by side. The two side walls of the scraper 12 are inclined from top to bottom to the center of the scraper 12 to form two symmetrical cleaning surfaces. There are anti-scratch pieces; the bottom of the riser 22 is bonded with bristles 14; the two slide bars 4 are connecte...

Embodiment 2

[0047] A preparation method of a scraper, the preparation method of the scraper mainly includes the following steps:

[0048] Step 1: Mix butyl rubber, calcium oxide, stearic acid, clay, coal tar pitch, silicon dioxide, glass fiber, iron oxide and aluminum oxide in the following parts by weight: 60-100 parts of butyl rubber, calcium oxide 2 to 7 parts, 1 to 3 parts of stearic acid, 4 to 8 parts of clay, 8 to 18 parts of coal tar pitch, 3 to 7 parts of silicon dioxide, 2 to 3 parts of iron oxide and 5 to 13 parts of aluminum oxide;

[0049] Step 2: Put the mixed raw material obtained in Step 1 into a smelting furnace for smelting. The smelting temperature of the smelting furnace is 130-180° C.; the smelting is carried out in two stages, and the first stage is carried out at 130-160° C. For the first smelting, the smelting time is 10-15 minutes. After the first smelting is completed, cool to room temperature and then perform the second smelting. The second smelting is smelting a...

Embodiment 3

[0055] A preparation method of a scraper, the preparation method of the scraper mainly includes the following steps:

[0056] Step 1: Mix butyl rubber, calcium oxide, stearic acid, clay, coal tar pitch, silicon dioxide, glass fiber, iron oxide and aluminum oxide in the following parts by weight: 60 parts of butyl rubber, 2 parts of calcium oxide , 1 part of stearic acid, 4 parts of clay, 8 parts of coal tar pitch, 3 parts of silicon dioxide, 2 parts of iron oxide and 5 parts of aluminum oxide;

[0057] Step 2: Put the mixed raw material obtained in Step 1 into the melting furnace for smelting. The smelting is carried out in two stages. In the first stage, the first smelting is carried out under the condition of 130°C. The smelting time is 10 minutes, and the first smelting is completed. After cooling to room temperature, the second smelting is carried out, and the second smelting is smelted at 160°C for 35 minutes; after the second smelting is completed, the temperature is kep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com