Preparation method of meteng fruit meal bioactive peptide with uric acid reducing effect

A bioactive peptide, the technology of satoshi fruit, which is applied in the field of preparation of bioactive peptides of satoko fruit meal, can solve the problems of unreported research on bioactive functions, achieve good absorption and utilization efficiency of human body, low production cost, and small molecular weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

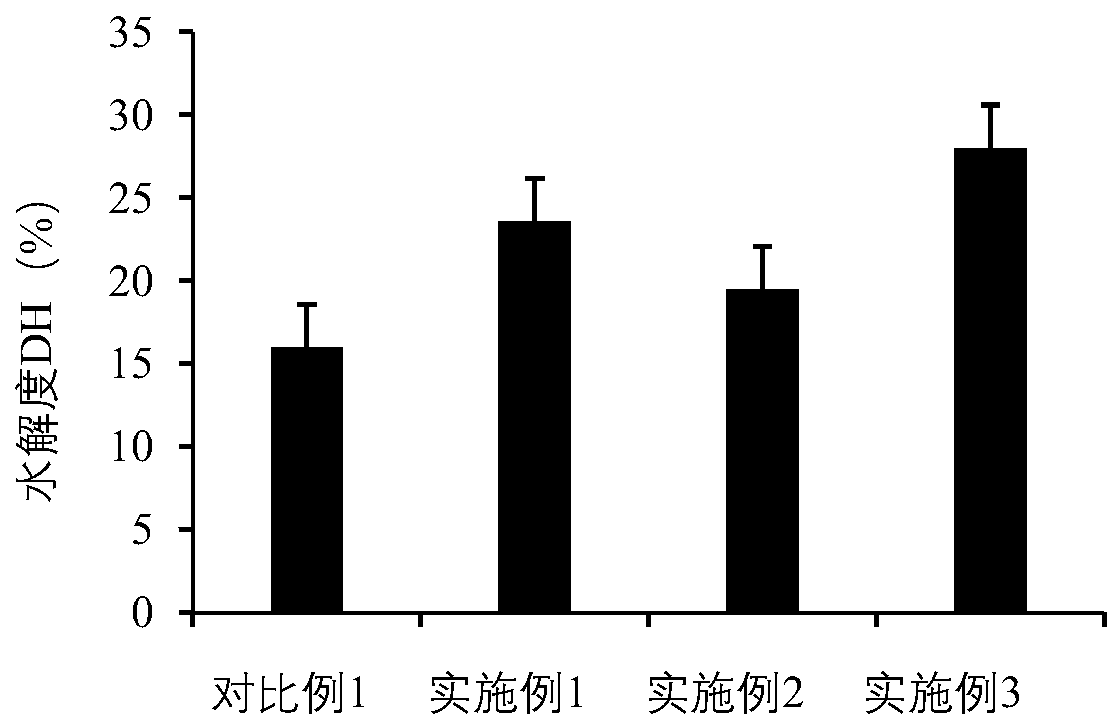

[0043] Example 1: Preparation of bioactive peptides with uric acid-lowering effect of sachaeji fruit meal

[0044] (1) Pre-treatment of satobi pulp

[0045] Pulverize the satoshi fruit cake and pass it through a 40-mesh sieve. After supercritical extraction and degreasing, dry it overnight in an oven until the organic solvent is completely removed. According to the weight ratio of satoshi fruit cake: distilled water = 1:25, add water and soak for 3 hours to obtain Satoko pulp solution;

[0046] (2) Protease hydrolysis

[0047]Using neutral protease to hydrolyze the cane fruit meal to prepare polypeptide. Heat the saiteng fruit meal solution to the optimum temperature of neutral protease hydrolysis at 45°C, use 0.1mol / L hydrochloric acid and sodium hydroxide to adjust the pH of the solution to 7, add 5% neutral protease, hydrolyze for 6 hours, and then set the temperature at 90°C Inactivate the enzyme at high temperature for 15 minutes, centrifuge at 4000 r / min for 10 minute...

Embodiment 2

[0054] Example 2: Preparation of bioactive peptides with uric acid-lowering effect

[0055] (1) Pre-treatment of satobi meal

[0056] Pulverize the satoshi fruit cake and pass it through a 40-mesh sieve. After supercritical extraction and degreasing, dry it overnight in an oven until the organic solvent is completely removed. According to the weight ratio of satoshi fruit cake: distilled water = 1:25, add water and soak for 3 hours to obtain Satoko pulp solution;

[0057] (2) Protease hydrolysis

[0058] Alkaline protease was used to hydrolyze the cane fruit meal to prepare polypeptide. Heat the saiteng fruit pulp solution to the optimum temperature of alkaline protease enzymatic hydrolysis at 50°C, use 0.1mol / L hydrochloric acid or sodium hydroxide to adjust the pH of the solution to 10, add 5% alkaline protease, hydrolyze for 6 hours, and heat at 90°C Inactivate the enzyme at high temperature for 15 minutes, centrifuge at 4000 r / min for 10 minutes, and take the enzymatic ...

Embodiment 3

[0065] Example 3: Preparation of bioactive peptides with uric acid-lowering effect of sachaeji fruit meal

[0066] (1) Pre-treatment of satobi meal

[0067] Pulverize the satoshi fruit cake and pass it through a 40-mesh sieve. After supercritical extraction and degreasing, dry it overnight in an oven until the organic solvent is completely removed. According to the weight ratio of satoshi fruit cake: distilled water = 1:25, add water and soak for 3 hours to obtain Satoko pulp solution;

[0068] (2) Protease hydrolysis

[0069] Trypsin was used to hydrolyze the cane fruit pulp to prepare polypeptides. Heat the saiteng pulp solution to the optimum temperature of trypsin enzymatic hydrolysis at 55°C, use 0.1mol / L hydrochloric acid or sodium hydroxide to adjust the pH of the solution to 9, add 5% trypsin, hydrolyze for 6 hours, and extinguish at 90°C Enzyme for 15 minutes, centrifuge at 4000 r / min for 10 minutes, and take the enzymatic hydrolyzate of cane fruit pulp in the supe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com