Feed for improving butter-fat percentage of ruminant and preparation method thereof

A technology for ruminants and feeds, which is applied in the field of feeds for improving the milk fat ratio of ruminants, can solve problems such as poor digestion and absorption, and achieve the effects of less loss of nutrients, easy absorption and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

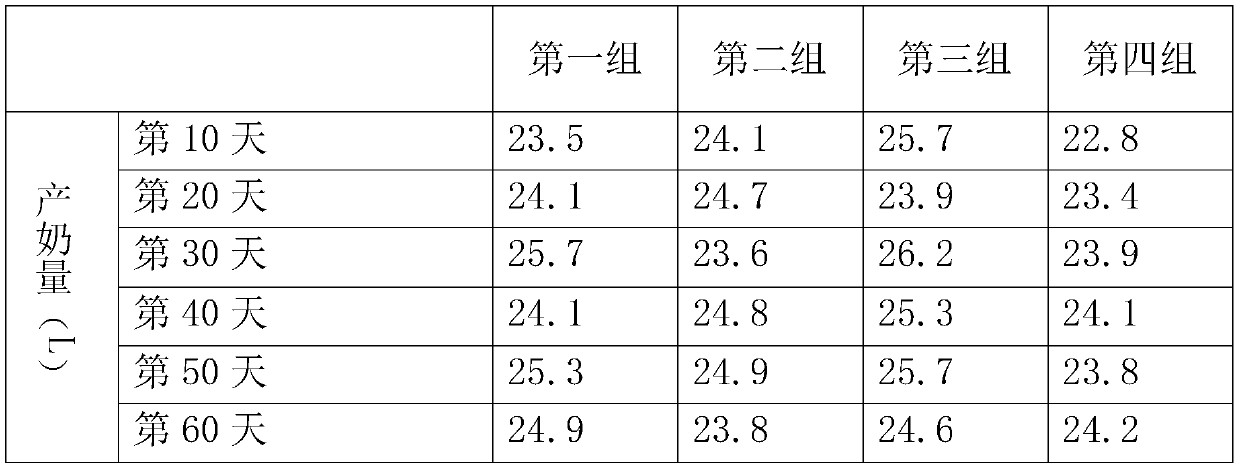

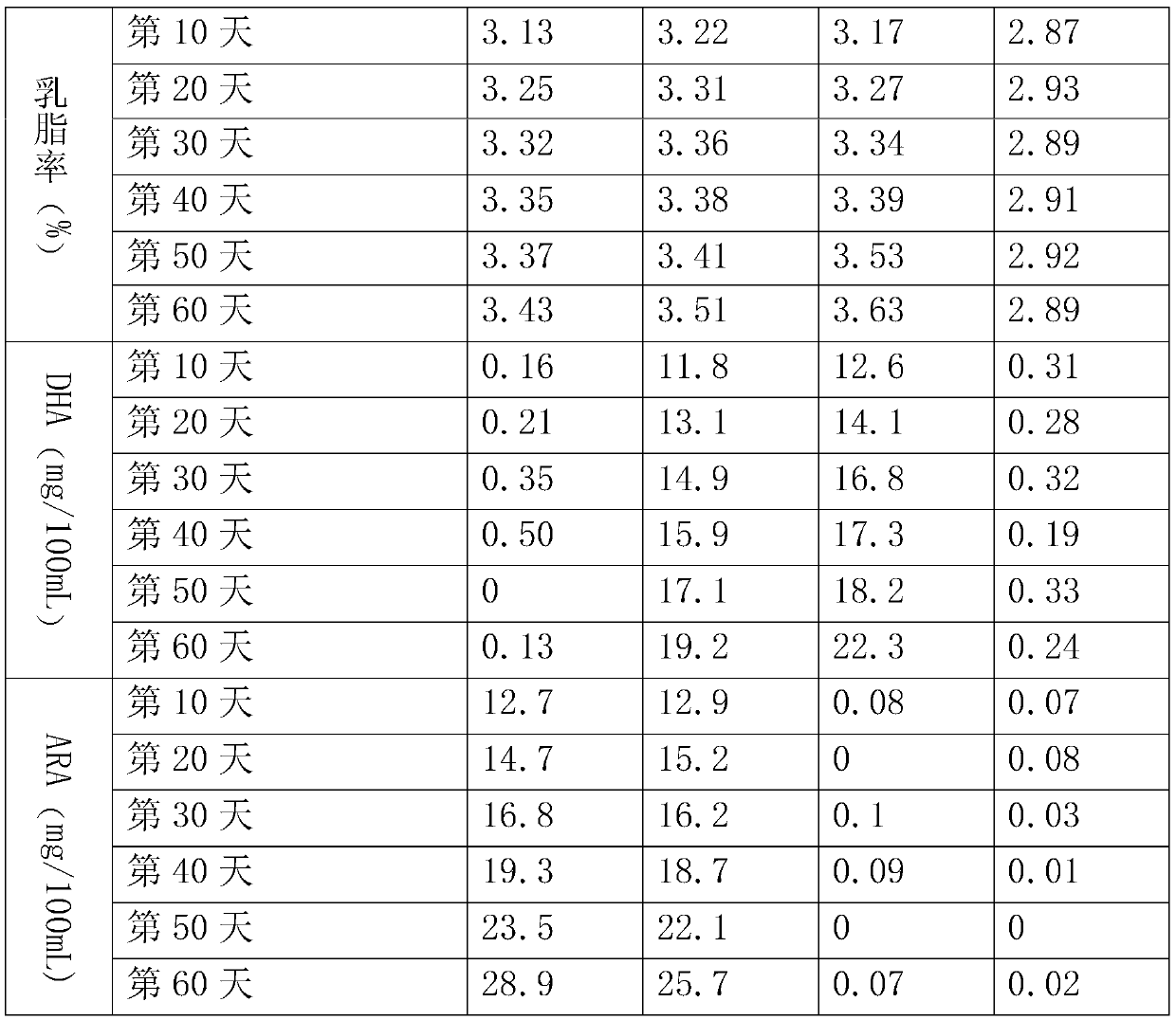

Examples

Embodiment 1

[0029] 1) The fermented broth of the alpine fermented mold is filtered with a plate and frame filter press to obtain wet cells with a water content of 57.8%. Take 100Kg of wet cells of Mortierella alpina, and use a sand mill to break the wall. The grinding medium uses zirconium beads. After the cells are ground, they flow out of the sand mill to obtain bacteria sludge with a particle size of 1-10 μm.

[0030] 2) Add 20Kg of maltodextrin, 12kg of sodium caseinate, 1.7kg of ascorbyl palmitate, 0.65kg of vitamin E and 50Kg of water for every 100Kg of wet bacteria. , ascorbyl palmitate, vitamin E and purified water, stirred evenly, and then ground with a sand mill to obtain the bacterial liquid.

[0031] 3) Spray-dry the bacteria solution prepared in the second step by using a pressure spray dryer, the feed pressure is 10-18 MPa, and the hot air temperature of the dryer is 150-185° C. to obtain bacteria powder.

[0032] 4) add thallus powder in the fluidized bed, take shellac acc...

Embodiment 2

[0034] 1) Take 50Kg of Mortierella alpina wet mycelium and 50Kg of Schizochytrium wet mycelium (filter the Schizochytrium fermentation liquid with a centrifuge), and use a sand mill to break the wall. The grinding medium uses zirconium beads. After the body is ground, it flows out of the sand mill to obtain the bacteria slime with a particle size of 1-10 μm.

[0035] 2) Add 18Kg of modified starch, 8Kg of lactose, 7Kg of maltodextrin, 10Kg of sodium ascorbate and 53Kg of water for every 100Kg of wet bacteria. The homogenizer performs homogenization on the bacterial liquid.

[0036] 3) Dry the bacterial liquid obtained in the second step by using an airflow spray dryer, first put 10 kg of maltodextrin into the material trolley of the airflow spray dryer, and heat the air at a temperature of 113-135° C. to obtain bacterial powder.

[0037] 4) Add bacterial cell powder into the material trolley of the coating drying tower, and add acrylic resin No. II as a rumen-passing protecti...

Embodiment 3

[0039] 1) Take 100Kg of wet bacterium of Wukenia, use a homogenizer to break the wall, the homogenization pressure is 35-62MPa, and the temperature of the feed liquid is kept at 65-72°C. The bacteria sludge with a particle size of 1-10 μm is obtained.

[0040] 2) Add sodium caseinate, solid corn syrup, phospholipids and purified water to the bacteria slime at a ratio of 1kg of sodium caseinate, 1kg of solid corn syrup, 0.5Kg of phospholipid, and 55Kg of water for every 100Kg of wet bacteria, and stir After uniformity, use a high-pressure homogenizer for homogenization.

[0041] 3) Dry the bacteria solution prepared in the second step by using a drum dryer, using 0.15-0.25 MPa steam during drying, and the temperature of the outer wall of the drum at 110-135° C. to obtain bacteria powder.

[0042] 4) Take polyvinyl alcohol acetate phthalate at a ratio of 20 parts by weight per 100 parts by weight of wet bacteria, and dissolve the polyvinyl alcohol acetate phthalate with water a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com